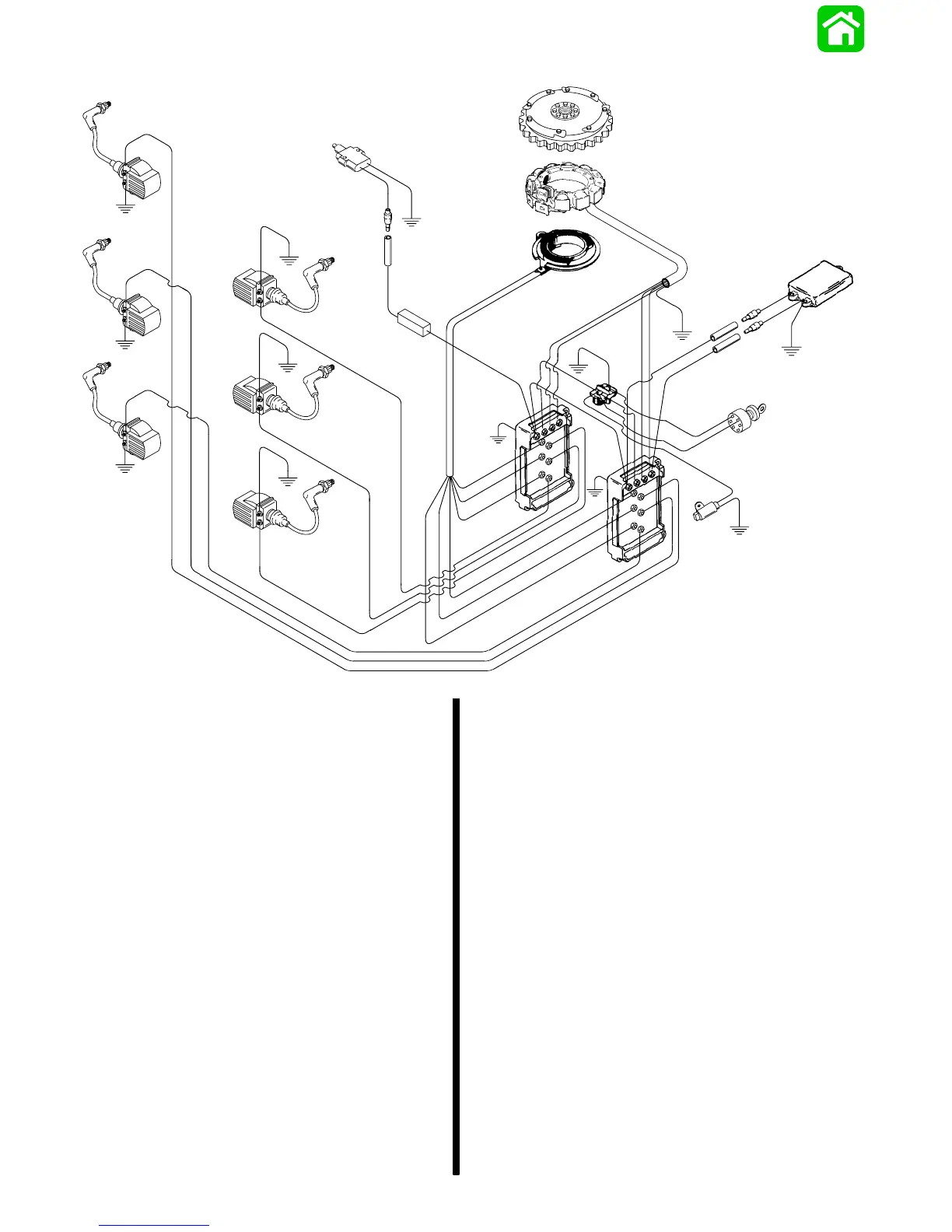

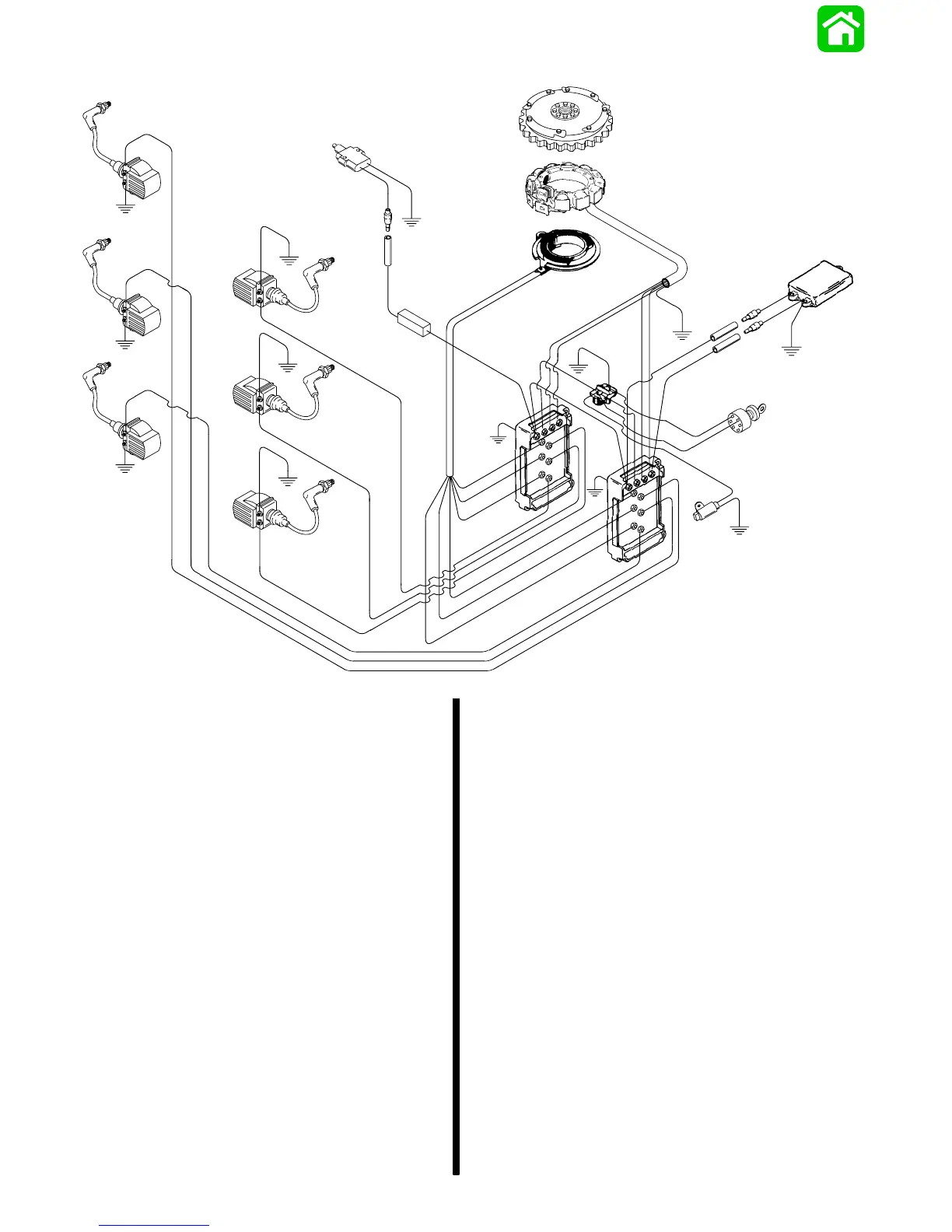

#2 Coil

#4 Coil

#6 Coil

#1 Coil

#3 Coil

#5 Coil

Flywheel

Stator

Trigger

Inner

Switch Box

Ignition Key Switch

Mercury

(Tilt)

Switch

Outer

Switch Box

Shift Interrupt Switch

Diode

Idle Stabilizer

2A-10 - ELECTRICAL 90-824052R3 JUNE 2002

Theory of Operation

Description

The V-6 outboard ignition system is alternator-driven

with distributor-less capacitor discharge. Major

components of the system are the flywheel, stator

assembly, trigger assembly, 2 switch boxes, 6

ignition coils and 6 spark plugs.

The stator assembly is mounted below the flywheel

and has 4 capacitor charging coils. The 4 capacitor

charging coils are composed of 2 high speed and 2

low speed coils-1 high speed and1 low speed coil for

each switch box. The low speed coils provide primary

voltage for the switch boxes from idle to approximate-

ly 2500 RPM. The high speed coils provide primary

voltage from 2000 RPM to the maximum RPM the

outboard is capable of achieving.

The flywheel is fitted with permanent magnets inside

the outer rim. As the flywheel rotates, the permanent

magnets pass the capacitor charging coils producing

AC voltage. The AC voltage is conducted to the

switch boxes where it is rectified and stored in a

capacitor.

The trigger assembly (also mounted under the fly-

wheel) has 3 coils. Each coil controls the spark to 2

cylinders -1 cylinder each bank. The flywheel also

has a second set of permanent magnets located

around the center hub. As the flywheel rotates, the

magnets pass the trigger coils producing AC voltage.

The AC voltage is conducted to an electronic switch

(SCR) in the switch box. The switch discharges the

capacitor voltage into the ignition coil at the correct

time and in firing order sequence.

Capacitor voltage is conducted to primary side of ig-

nition coil. As this voltage goes to ground through the

primary circuit of the coil, it induces a voltage rise in

the secondary side of the ignition coil. This voltage

can increase to approximately 40000 volts before

bridging the spark plug gap and returning to ground.

The preceding sequence occurs once per engine

revolution for each cylinder.

Spark timing is advanced or retarded by the move-

ment of the trigger assembly attached to the throttle/

spark arm.

Loading...

Loading...