6E-26 - LOWER UNIT

90-824052R3 JUNE 2002

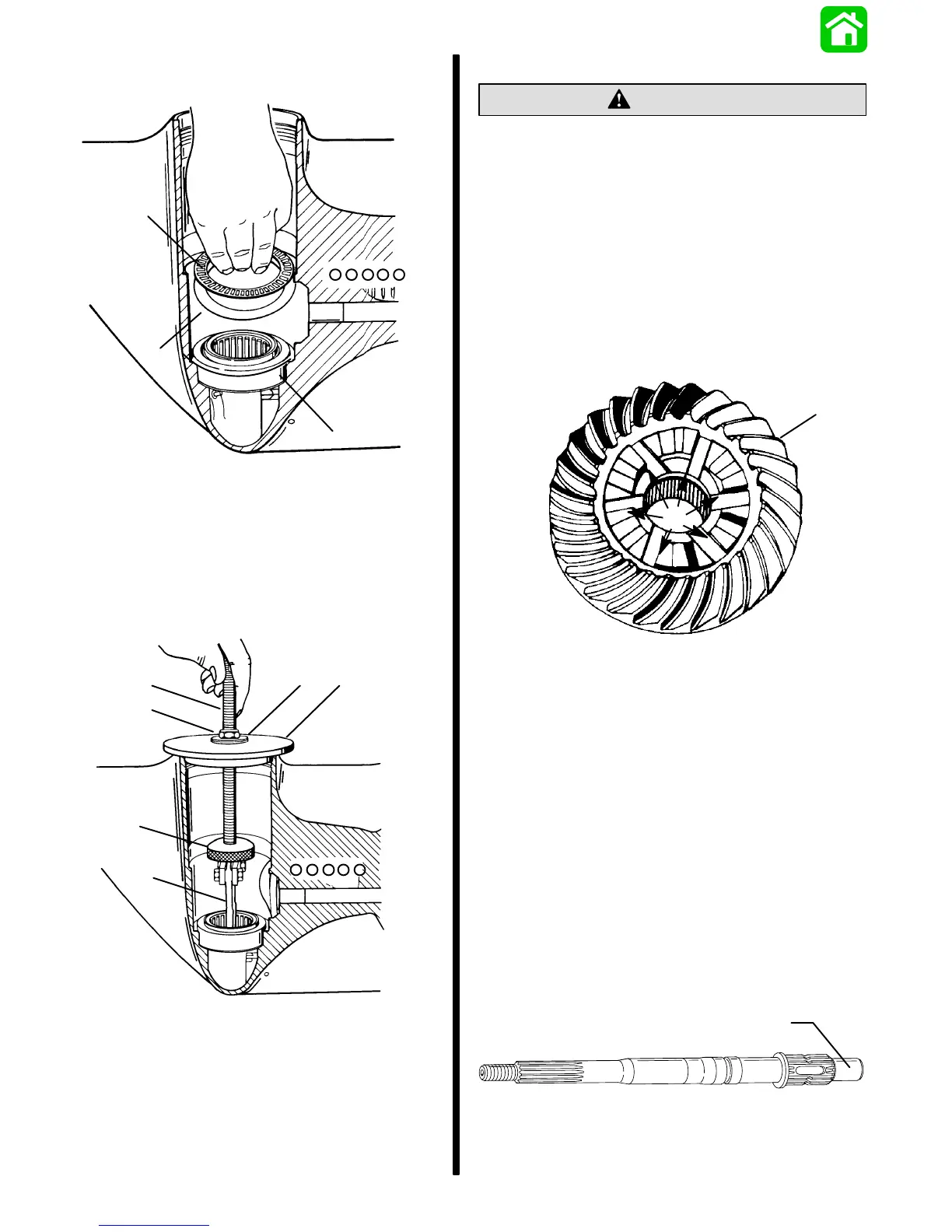

2. Remove thrust bearing and thrust washer from

reverse gear bearing cup.

50882

a

b

c

a - Thrust Bearing

b - Thrust Washer

c - Reverse Gear Bearing Adaptor

3. Remove reverse gear bearing adaptor. Remove,

measure and make note of the shim thickness

and discard (DO NOT reuse) the shims.

50780

a

b

c

d

e

f

a - Bolt (91-31229)

b - Nut (91-11-24156)

c - Guide Plate (91-816243)

d - Washer (91-34961)

e - Puller Head (from Slide Hammer Puller Kit 91-34569A1)

f - Jaws (91-816242)

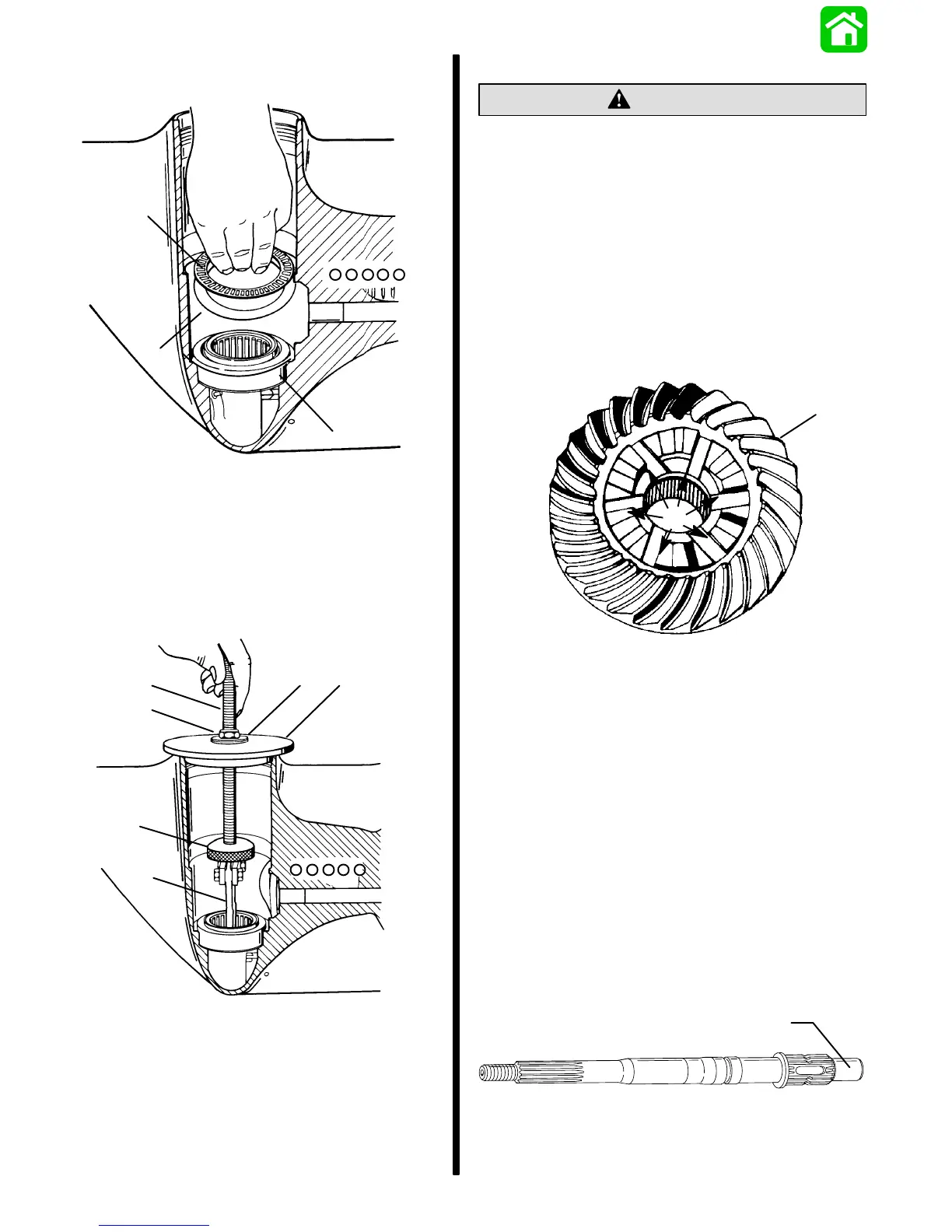

CLEANING AND INSPECTION

CAUTION

DO NOT spin bearings dry with compressed air,

as this could cause bearing to score.

1. Clean reverse gear and bearing with solvent and

dry with compressed air. DO NOT spin the

bearing.

2. Inspect gear teeth for pitting, grooves, scoring,

uneven wear and for discoloration (from over-

heating). Replace gear if any of these conditions

are found.

3. Check clutch jaws on reverse gear for damage.

Replace reverse gear if damage is found.

23351

b

a

a - Reverse Gear Teeth

b - Clutch Jaws

NOTE: The needle bearings in the reverse gear

should not be removed unless damage has been

found. Inspect to ensure that all of the needles are

present and in position. Needles that have been

dislodged may be snapped back into place as long as

no damage has occurred to the bearing cage.

4. Inspect the needle bearings on the inside of the

reverse gear and the bearing surface on the

propeller shaft. If either the needle bearings or

the bearing surface of the propeller shaft is pitted

grooved, worn unevenly, discolored from

overheating or has embedded particles, replace

the propeller shaft and needle bearing in the

reverse gear.

a

a - Reverse Gear Needle Bearing Contact Area

Loading...

Loading...