POWERHEAD - 4B-990-824052R3 JUNE 2002

Water Pump Cleaning and Inspection

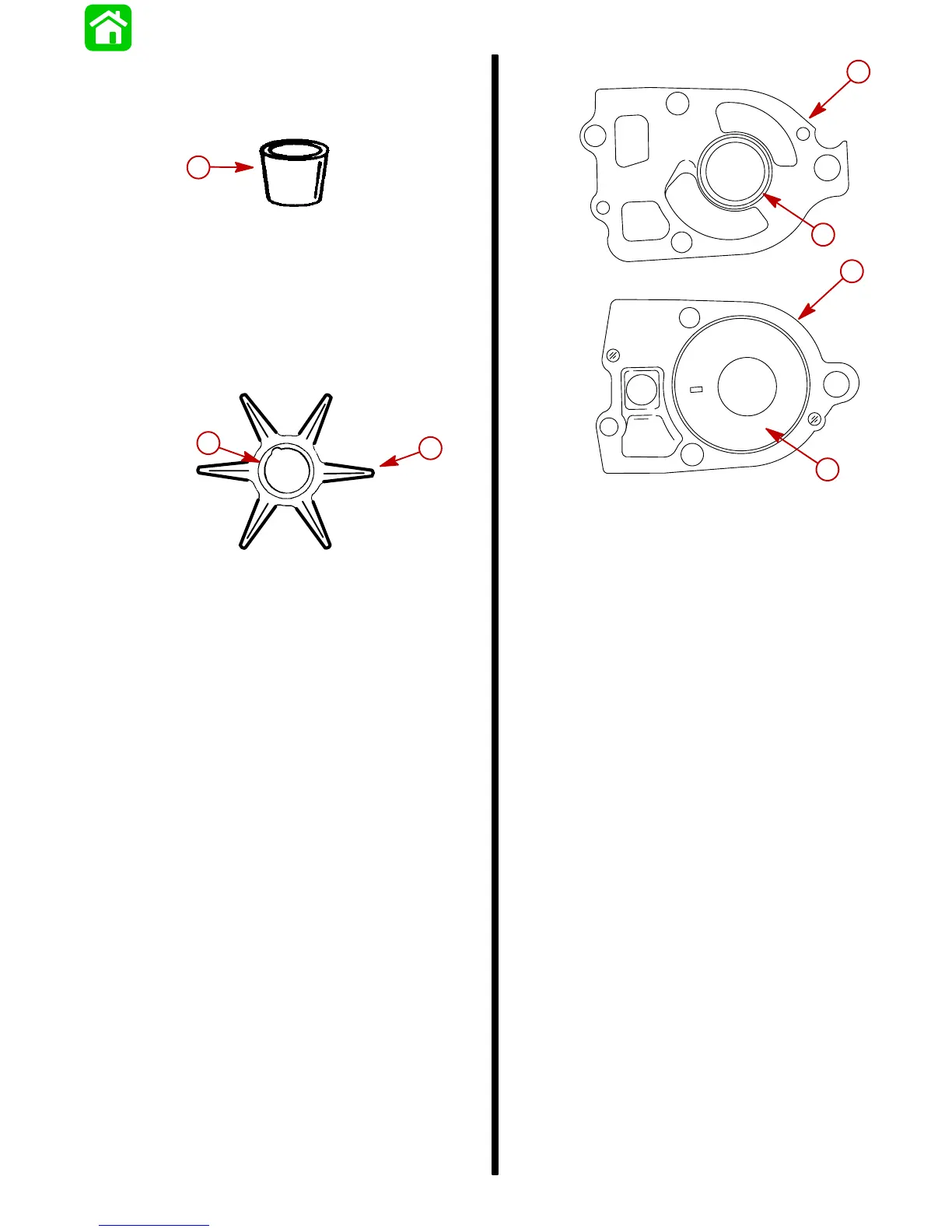

1. Inspect the water tube coupling for wear or dam-

age. If necessary replace..

a

a-Water Tube Coupling

2. Inspect the water pump impeller for wear on the

end, top and bottom of the impeller blades. Re-

place the impeller if this condition is found.

3. Inspect for proper bonding between the hub and

the impeller. Replace the impeller if improper

bonding is found.

a

b

a-Hub

b-Impeller

4. Inspect the impeller blades to see if they are

cracked, burnt, hard or deformed. Replace the

impeller if the blades are in this condition.

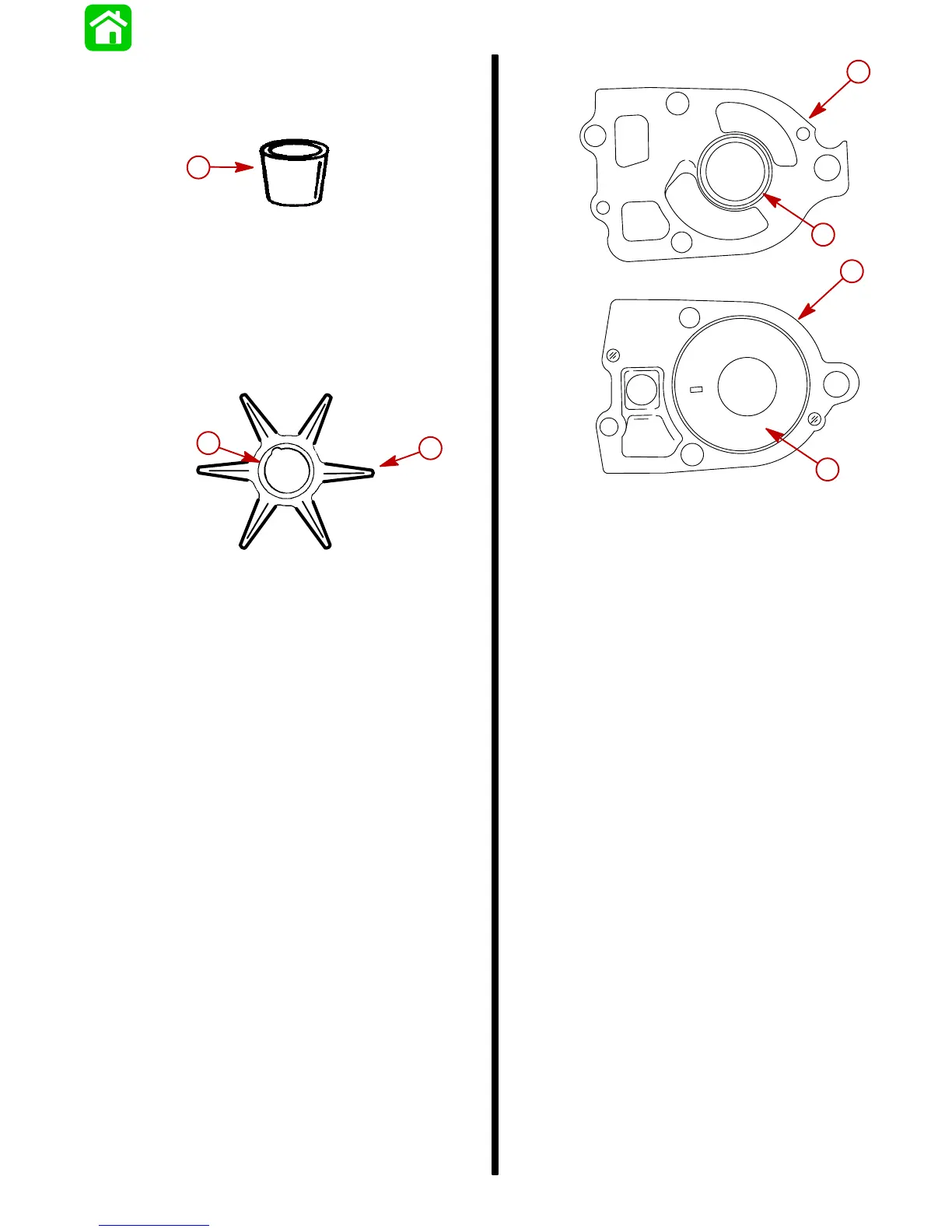

IMPORTANT: The circular groove formed by the

impeller sealing bead should be disregarded

when inspecting cover and plate. The depth of

the groove will not affect water pump output.

5. Replace cover if plastic is melted from excessive

heat (lack of water). Replace stainless insert and/

or face plate if grooves (other than impeller seal-

ing bead groove) are more than 0.010 in. (0.254

mm) deep.

57408

a

b

c

d

a-Water Pump Face Plate

b-Sealing Groove (disregard)

c-Water Pump Cover

d-Stainless Insert [discard if grooves exceed

0.010 in. (0.254 mm)]

IMPORTANT: It is recommended that all seals and

gaskets be replaced (as a normal repair proce-

dure) to assure effective repair.

IMPORTANT: It is recommended that the water

pump impeller be replaced whenever the gear-

case is removed for maintenance. However, if it

is necessary to re-use the impeller, DO NOT

install in reverse to original rotation as premature

impeller failure will occur.

Loading...

Loading...