Chapter 4 – General Configuration

Firmware Version 3/4.31.37

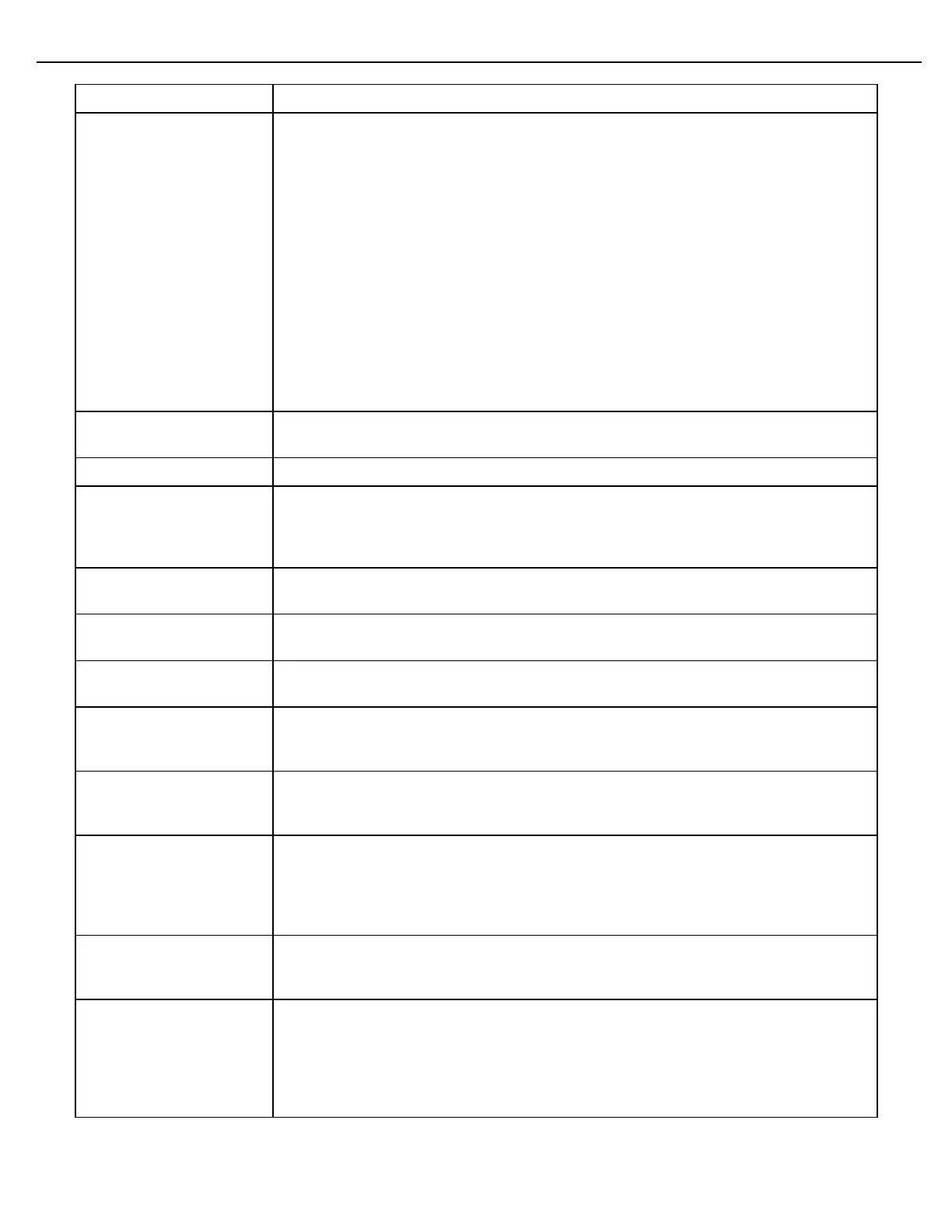

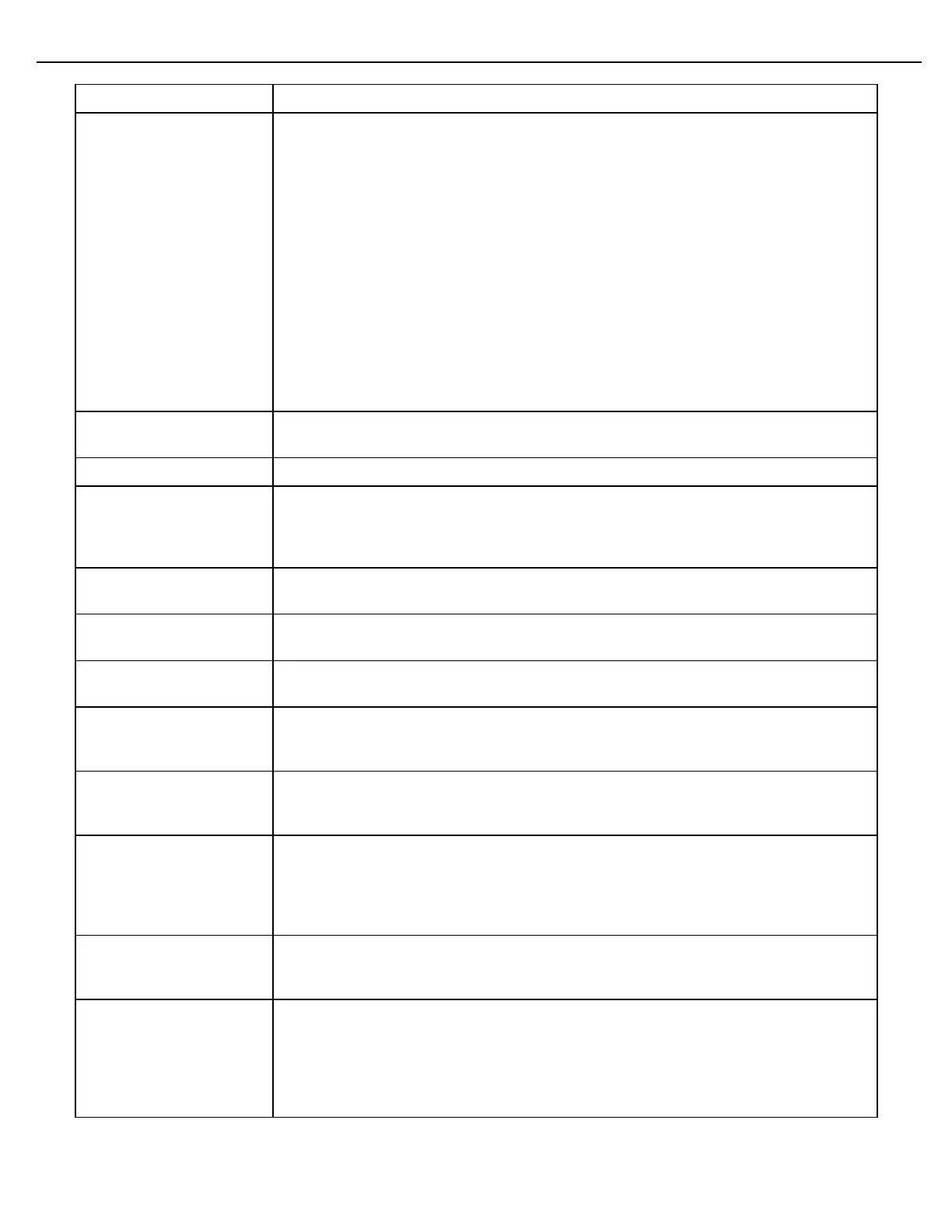

Blending Type

(Excluding SMP & SCS)

Possible modes:

RATIO:

Enables Ratio Blending. Multiple flow meters and control valves are required for ratio

blending. Enable this parameter if multiple flow meters and control valves are

assigned to the load arm and Ratio Blending is desired.

SEQ:

Enables Sequential Blending. Enable this parameter if using one flow meter in the

preset, with multiple components. For single component loading through a single

flow meter, this parameter can be disabled.

RAT+SEQ:

Enables both options as above described.

WATERCT:

This mode will calculate the amount of oil and water. Need to have 2 components

setup and bsw sensors or default bsw is needed.

Enables select blending and recipe parameters for this preset to be under W&M

control.

Enter the target flow rate that will be used during the proving run.

This parameter defines the flow rate that will trigger the Excess Flow Rate Alarm. A

flow rate is considered excessive if it exceeds the absolute maximum rate that the

load arm is rated for. The value of this parameter should be higher than the High

Flow Rate parameter in the Preset Menu.

Defines the volume of overrun that will trigger the Overrun Volume Alarm. The

overrun volume is the volume of product delivered that exceeds the preset quantity.

After the initial start of a batch, the flow rate will be maintained at the Low Flow Start

target flow rate until the Low Flow Start Volume has been delivered.

When restarting an interrupted batch, the flow rate will be maintained at the Low Flow

Start flow rate until the Low Flow Restart volume has been delivered.

This rate specifies the Low Flow target flow rate. This rate will be maintained until the

Low Flow Start Volume has been delivered. This rate will also be used for the Low

Flow Restart stage.

This parameter specifies the High Flow target flow rate. Maximum flow through the

load arm is determined by this rate. This rate will be maintained until the 1

st

Stage

Trip Volume has been reached.

During the proving process, delivery into a proving vessel will begin at a Low Flow

Rate, until the value specified by this parameter has been delivered. Enter a value

that will determine how much volume will be delivered at the Low Flow Rate.

Typically the required Low Flow Start Volume for a proving delivery is less than the

Low Flow Start Volume of a normal delivery.

Line Flush Vol

(Excluding SMP & SCS)

Specify the volume of product required to flush the pipe segment that lies between

the flow meter and the end of the load arm. When this parameter is set to zero, the

Line Flush feature is disabled.

Line Flush Min Vol

(Excluding SMP & SCS)

Specify the volume of line flush that will be acceptable if the actual Line Flush

Volume is not reached. If the Line Flush Minimum Volume fails to be delivered, the

line flush alarm will activate. This parameter is intended to prevent nuisance alarms

due to small, acceptable deviations from the Line Flush Volume. The Minimum Line

Flush Volume will be the Flush value displayed on the status screen and that value

will decrement as the line is flushed.

Loading...

Loading...