Chapter 4 – General Configuration

Firmware Version 3/4.31.37

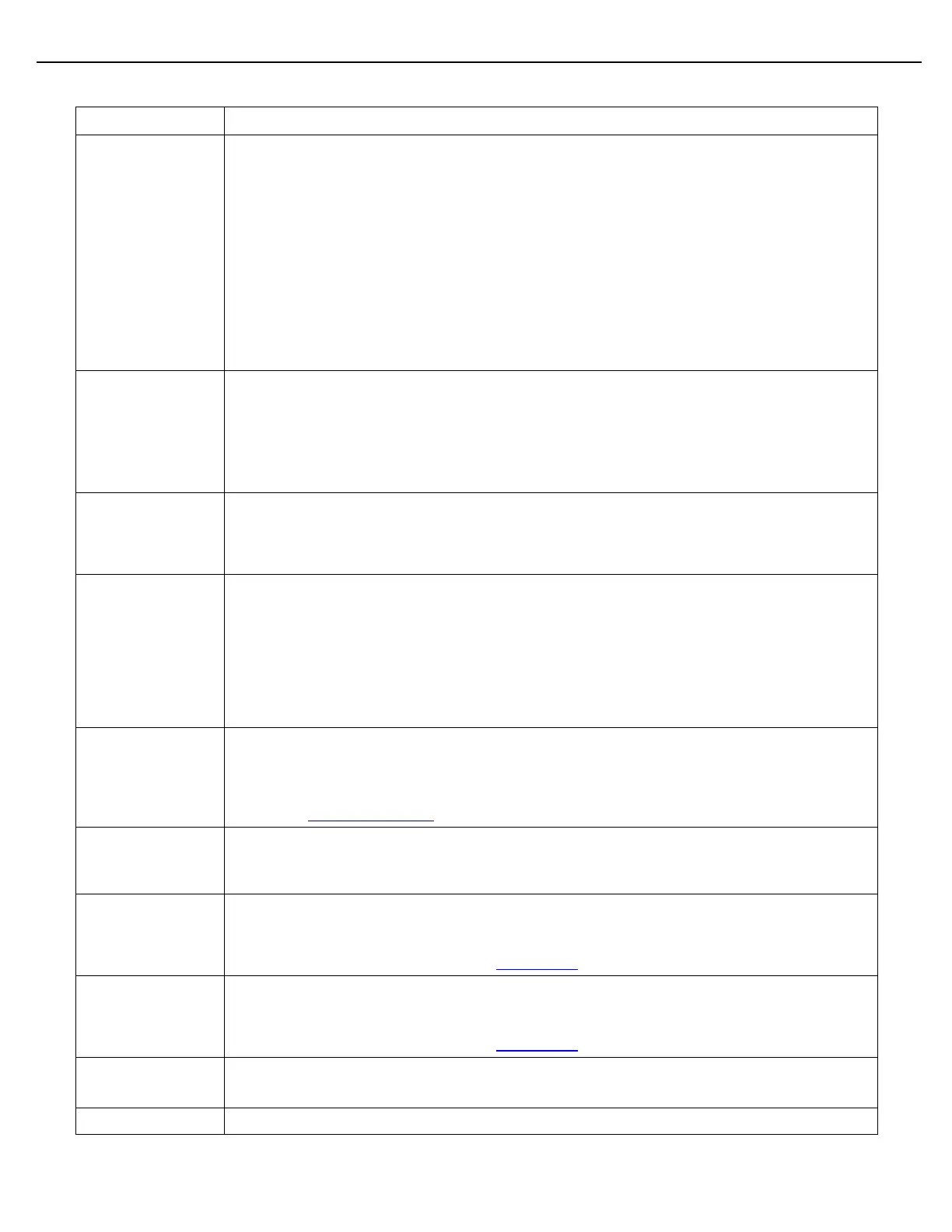

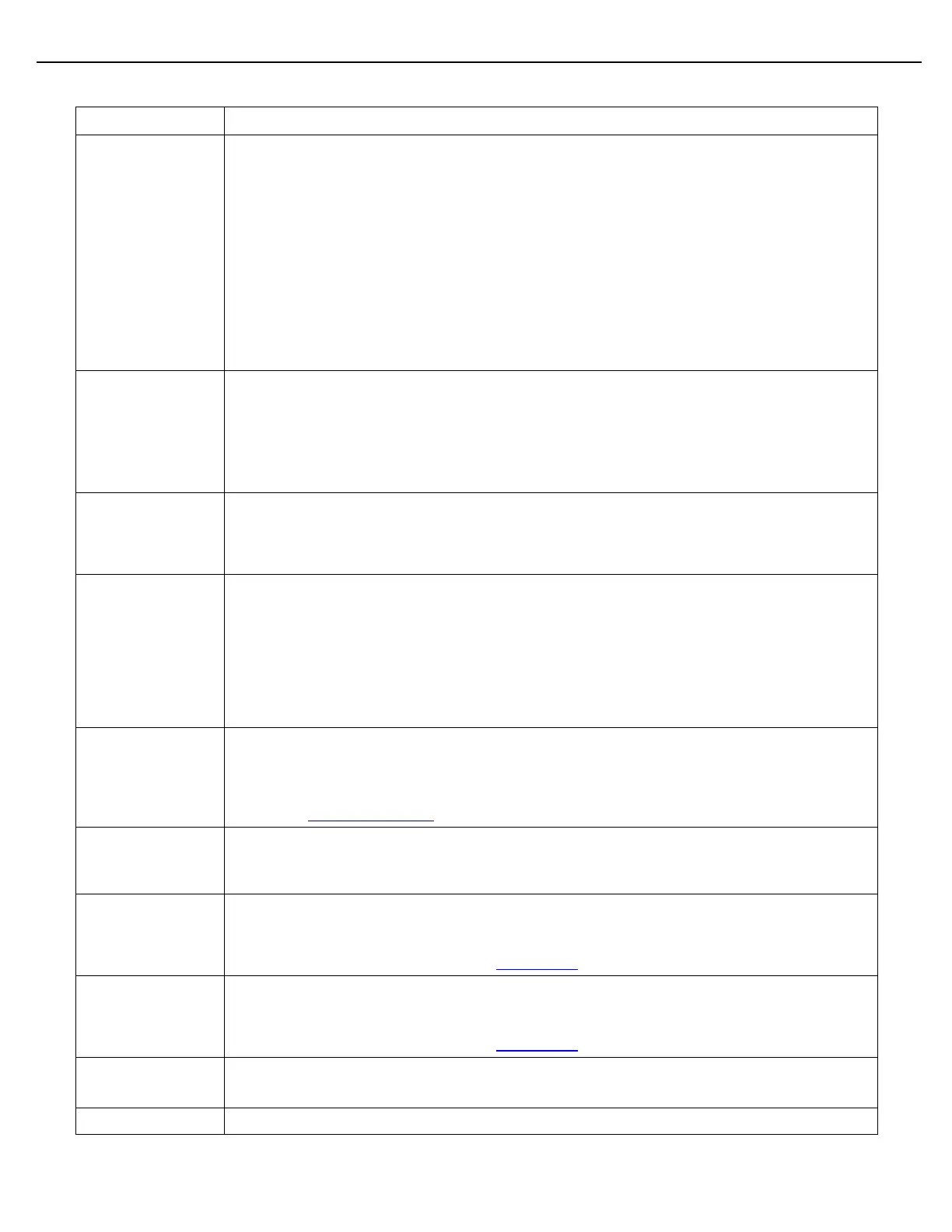

Quadrature Encoder error, also known as pulse security error. This alarm applies to flow

meters that use dual-channel pulsers. One of the pulser channels has failed or is failing

intermittently. This alarm occurs in new installations when pulser channel A is wired to

pulser channel B and vice versa. This alarm will also be raised if reverse flow is detected.

1. Verify that meter pulsers or pre-amps are receiving power.

2. Verify pulser connections to the I/O board.

3. Ensure that channel A and channel B pulsers are not wired in reverse.

4. Check for evidence of reverse flow by viewing the meter totalizer (backflow

gross).

This alarm indicates that the value measured by the Density or Relative Density Sensor has

deviated from the range specified by Alarm Low Density and Alarm High Density or Alarm

Low Relative Density and Alarm High Relative Density parameters.

Other potential causes include a disconnected sensor or an inappropriate value in the

Default Density or Default Relative Density field. Go to program mode menu Views &

Inquiries -> Density or Relative Density to observe the current density reading.

This alarm indicates that the temperature measured by the RTD has deviated from the

range established by the Alarm Low Temp and Alarm High Temp parameters. Other causes

include a disconnected sensor or misconfigured Temp Module Type parameter. Go to

program mode menu Views & Inquiries ->Temperature for further diagnostic messages.

Valve Control error-This alarm indicates that the control valve was unable to maintain flow

within the Dead Band (DB) Rates prescribed in the Meter menu. This alarm may indicate a

need for valve maintenance or that insufficient pressure is available to control the valve.

Use the Component Status screen to determine if the valve is able to achieve target flow

rates specified by High Flow Rate, Low Flow Rate and the 1

st

and 2

nd

Trip Rates. If valve is

operating in a wide open position and cannot achieve flow targets, the valve is vulnerable to

control problems, due to weak differential pressure. If this is the case, reduce flow rate

targets to achievable values or enable the Fallback feature in the Component menu.

This alarm indicates that volume has passed through the flow meter while the valve was not

commanded to open. It may be an indication of a small leak or it may indicate that

erroneous flow signals have been noted by the system. The amount of volume that triggers

the alarm is configured in the Meter Creep Alarm Volume parameter. Also consider the

parameter Creep Reset Time.

This alarm indicates that the pressure measured by the pressure transmitter has deviated

from the range established by the Alarm Low Pressure and Alarm High Pressure

parameters. Verify transmitter operation.

This alarm message indicates that pulses from the referenced meter’s A channel pulser is

not being received at port 4 of the FCM or they are being received intermittently. If this

alarm is received along with QUAD CHB alarm, the meter channels are either wired in

reverse or backflow is occurring. See QUAD ENC alarm.

This alarm message indicates that pulses from the referenced meter’s B channel pulser are

not being received at port 5 of the FCM or they are being received intermittently. If this

alarm is received along with QUAD CHA alarm, the meter channels are either wired in

reverse or backflow is occurring. See QUAD ENC alarm.

No communication with Meter that is connected via a communication line

This alarm indicates that the value measured by the BSW Sensor has deviated from the

Loading...

Loading...