Chapter 5 – Product Flow Control

Firmware Version 3/4.31.37

Whenever the flush component is being delivered outside of the flush stage, the minimum flush requirement on

the Status screen will return to zero, as the Line Flush Minimum Volume is achieved. This register immediately

increases to the Line Flush Minimum Volume value as soon as any non-flush component is delivered into the line.

Consider the example of a sequential blend where component #1 is the flush component but the load is aborted

during component #1 delivery; component #2 nor the Flush is delivered. Although technically the flush never

occurred, the Flush feature will not alarm since it knows that the line is filled with component #1, which happens to

be the flush component. The alarm will not activate, provided that the minimum flush requirement was met during

component #1 loading.

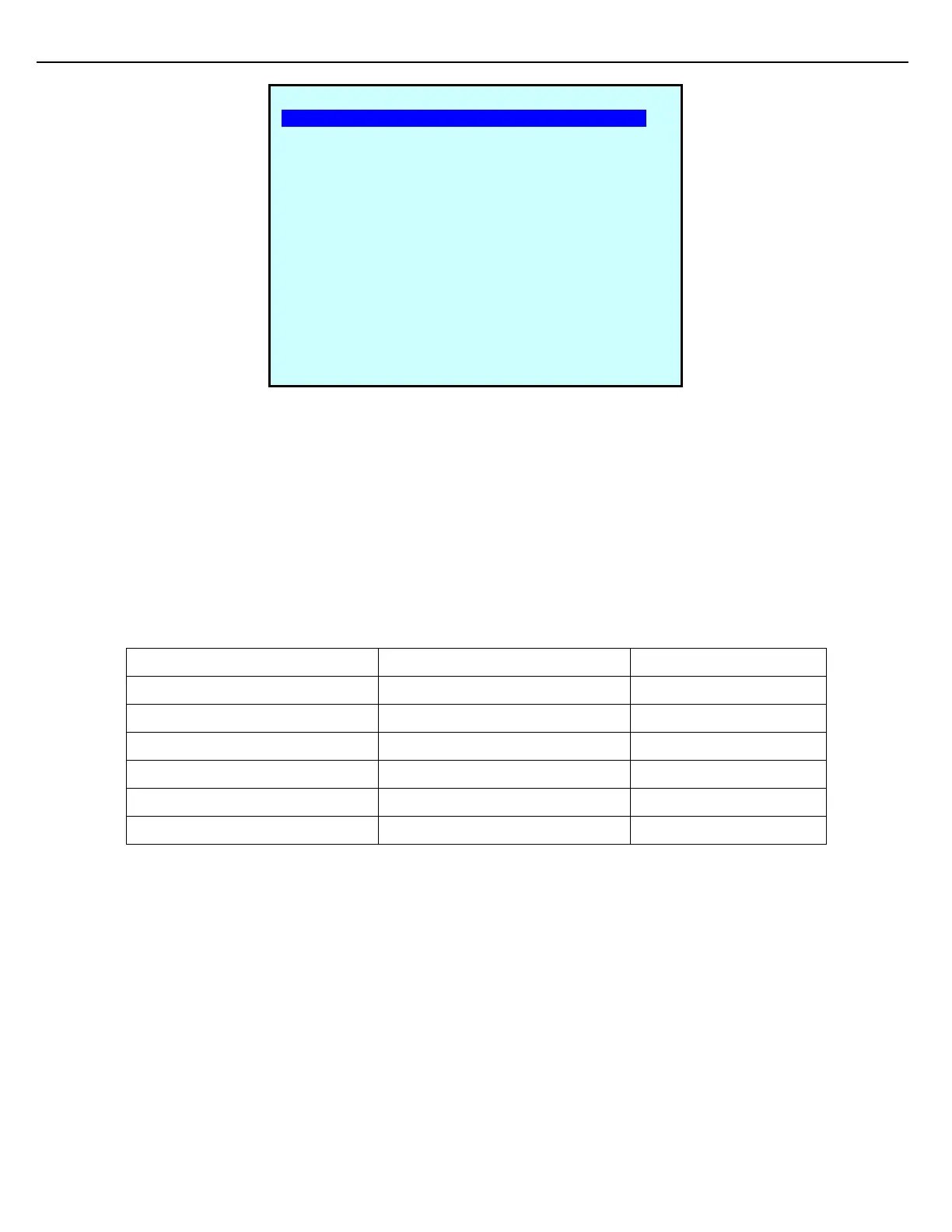

To deactivate the Line Flush feature, set the values of the first three parameters in the table below to zero. The

remaining flush parameters are related to blending.

Line Flush Minimum Volume

0 (no component selected)

Take Line Flush From Match

Take Line Flush From First

Take Line Flush From Last

Line Flush and Blending

When blending multiple components through a load arm, one of the product components will have to be shorted

by a volume equal to the Line Flush Volume. There are three Line Flush parameters that can be configured to

determine which component is shorted. The MultiLoad will consider each parameter in the order that it is listed in

the table above. If the conditions of the first parameter do not resolve the question of which parameter to short,

the parameter that follows the first will be considered, and so on.

The first decision parameter is Take Line Flush From Match. This parameter, if enabled, will instruct the

MultiLoad to determine if the flush component is used in the product. If the Flush Component is used in the

product, it will short that component by the Line Flush Volume amount. The deficit will be made up during the

Line Flush stage. If the flush component is not used in the product recipe or if the parameter is disabled, the

MultiLoad will look to the next parameter for instruction.

The second decision parameter is Take Line Flush From First. This decision will be considered if the previous

parameter is disabled or if the previous decision was not resolved. If this parameter is enabled, the MultiLoad will

PRE #1 (Preset 001) SETUP

Line Flush Vol: 0

Line Flush Min Vol: 0

Line Flush Comp#: 0

Take L.F. from Match: ENABLED

Take L.F. from First: DISABLD

Take L.F. from Last: DISABLD

Alf. High Delay: 0

Stop Start Delay: 0

Blnd Chk Start Vol: 60

Blnd Chk Restart Vol: 10

Blnd Chk Alarm %: %5.00

Blnd Chk Alarm Vol: 25

Blnd Chk Alarm Time: 10

Blnd On Lead Comp: DISABLD

Next Prev Exit Enter

Loading...

Loading...