Ground drive and Rear Axle Service 9980 Self-Propelled Peanut Combine

Install Front Wheels – Dual Wheels

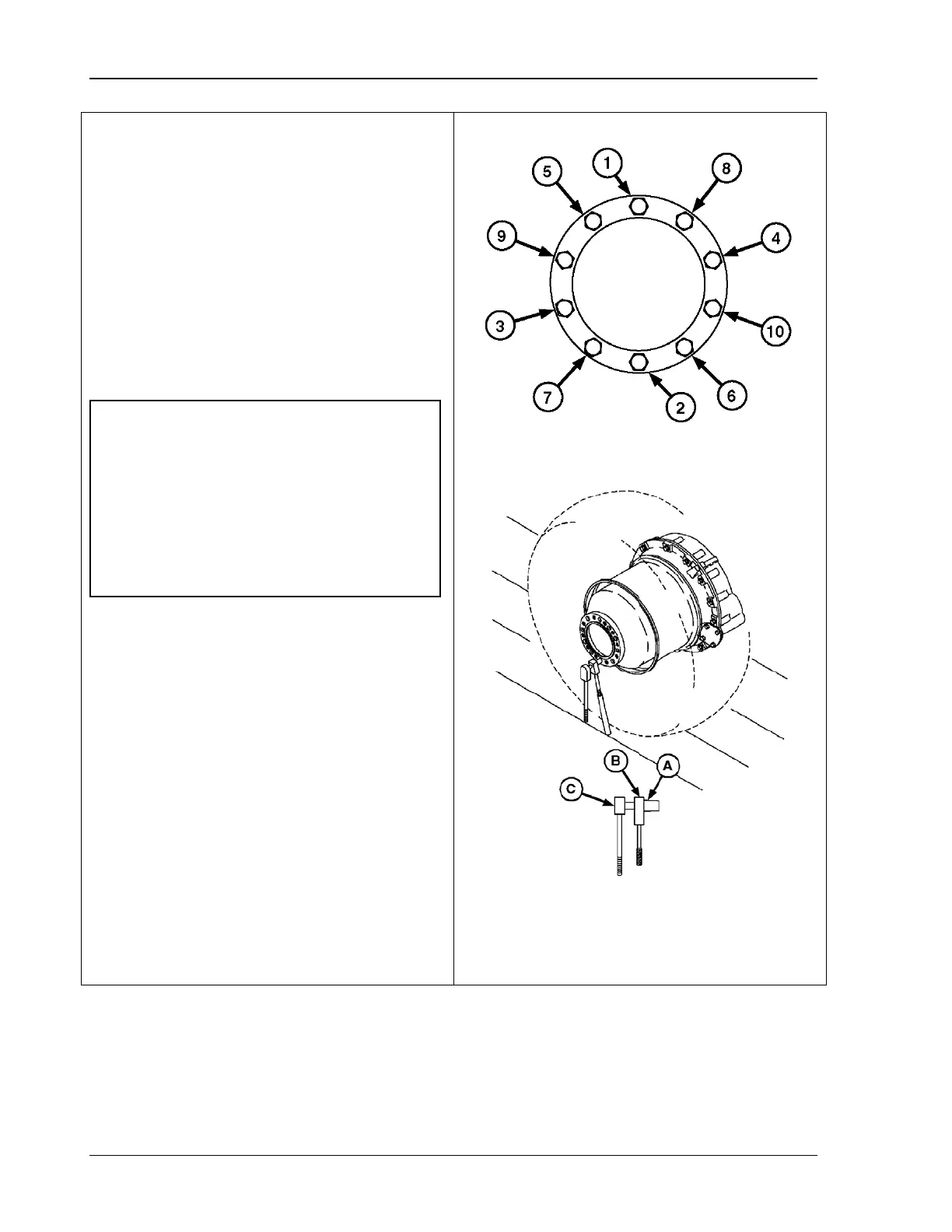

5.

Torque the wheel bolts to the following

specification for the initial wheel bolt

torque. Use a criss/cross pattern as

shown in the sketch to eve

wheel tightly against the hub.

Torque = 200 Nm (150 lb-ft)

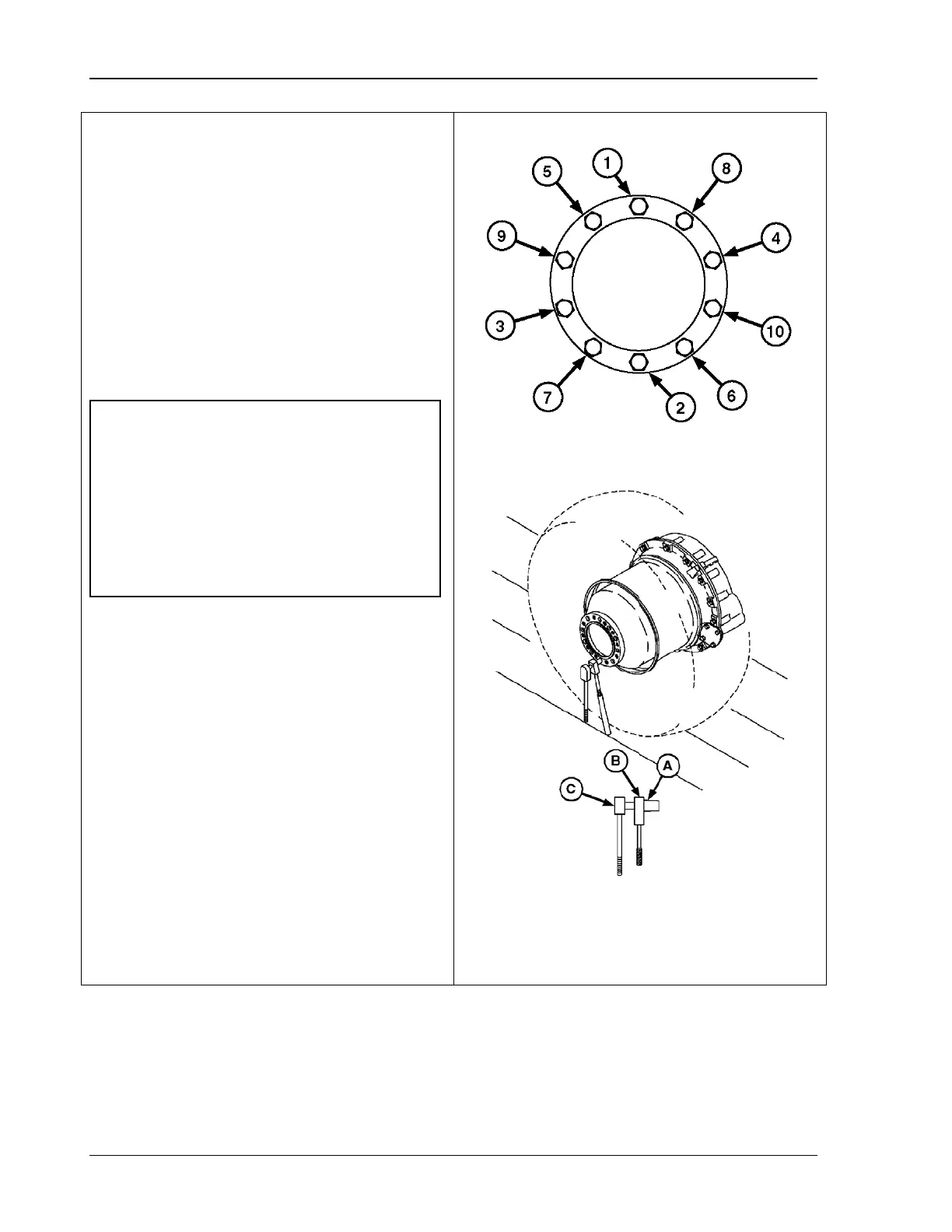

6.

Once the initial torque is complete, make

sure a final torque is done. Position tools

(A-C) on the wheel and turn bolt heads ¼

turn past the initial torque (ratchet/torque

wrench will make a full turn).

7. Repeat steps on opposite side of machine.

A -30 mm socket

B – 4-to-1 torque multiplier

C – Torque or ratchet wrench

IMPORTANT! Final wheel bolt torque is

extremely high and cannot be used using

common hand tools and a torque wrench.

A Four-to-One Torque Multiplier is required

to meet final wheel bolt torque

specifications. To achieve high torque

results, final torquing must be done with

tires on ground and with multiplier handle

against inside of rim.

286 09/04/15 MAN141

Loading...

Loading...