Information

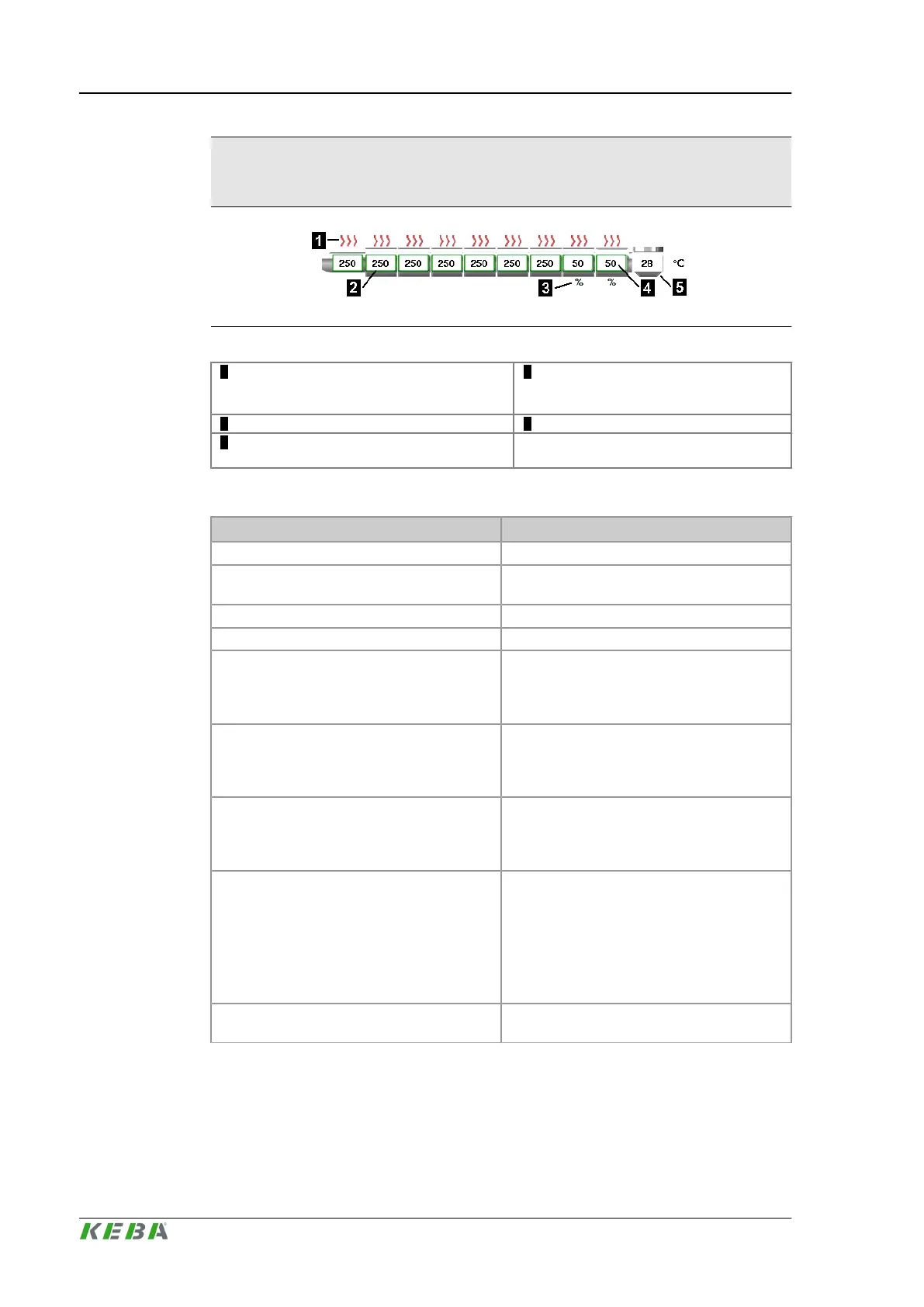

The display depends on the number of heating zones (maximum of 9).

Fig.4-2: Depiction of the heating zones

1 ... Status of the heater (zone is heating / not

heating, error of a heating zone )

2 ... Status of the heater (grey....temper-

ature out of tolerance, green...target

temperature attained)

3 ... %....displays a setter zone 4 ... Actual temperature

5 ... Displays a hopper zone for material en-

trance

Overview data

Designation Description

Pressure Actual system pressure

Velocity

Actual system velocity (displayed in percent-

age of maximum pump flow rate).

Screw rotation Actual screw revolution

Back pressure Actual back pressure

Ejector position

Actual position of ejector in reference to its zero

position (ejector fully retracted. To the left and

right of the analog bar, status marker show if

the ejector has reached on of its end position.

Mold position

Actual distance from movable half of mold to

fixed half of mold. To the left and right of the

analog bar, status marker show if the molf has

reached on of its end position.

Screw position

Actual position of screw in reference to front

end point (end position). To the left and right of

the analog bar, status marker show if the screw

has reached on of its end position.

Nozzle position

Actual position of nozzle, relative to reference

point.. To the left and right of the analog bar,

status marker show if the screw has reached

on of its end position.

This display field is only shown if a transducer

is installed to determine the position of the noz-

zle.

Core position

Actual position of the cores (core in / core out)

displayed by status marker.

Description of the operating masks KePlast.HMI.KVB

© KEBA 2016

User's manual V3.0540

Loading...

Loading...