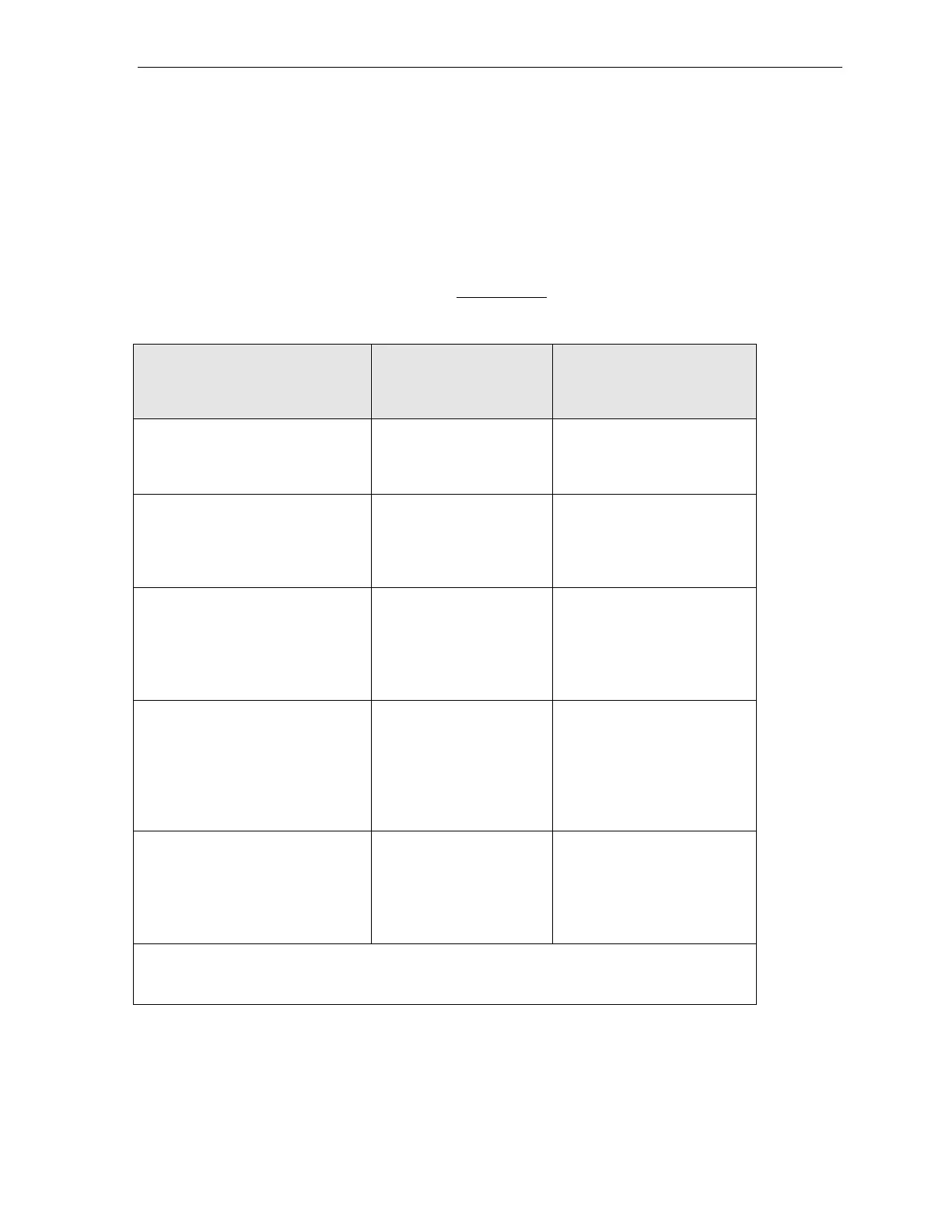

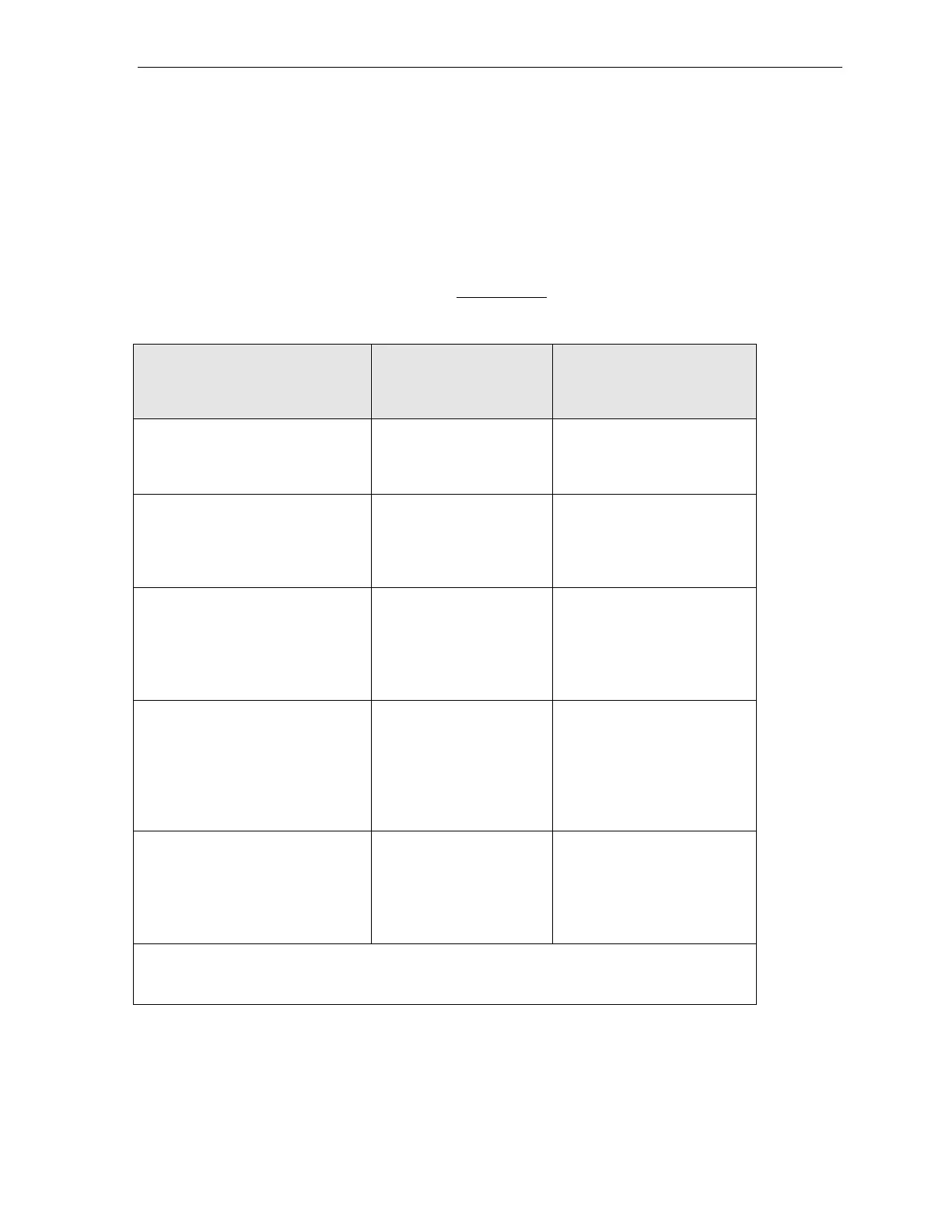

Operations and Maintenance Manual Preventive Maintenance Schedules

Version 1.2 - June 2004 10 - 7

7-DAY OR 5,000 WAFERS

PREVENTIVE MAINTENANCE SCHEDULE

WARNING:

Confirm that the diamond wheel is not spinning before beginning any maintenance

inspection or procedure.

SUBJECT

ACTION

ESTIMATED TIME TO

COMPLETE

• Control Computer, Robot

Controller, Pre-Aligner

Controller

Clean the air cooling

system.

Procedure will take approx.

10 min.

• D.I. Water Pressure

Check for adequate

pressure--30 psi

required.

Time required to check is

dependent upon customer

equipment (customer

facilities supplied filter).

• Drain Pans For Grinding

Chamber and Wafer Handling

Area

Check/clean. Refer to

“Notes” below.

Requires approx. 2 min. to

check. Corrective

procedure will take approx.

10 min.

• Grind Pan and Diamond

Wheel Housings

Clean.

Procedure requires approx.

20 min.

Frequency: After grinding,

when machine will sit idle

for long periods, or weekly.

• Grind Seals

• Clean.

• Apply a light film of

Molykote III (Dow

Corning ) lubricant.

Procedure requires approx.

5 min.

↓ (TABLE CONTINUED BELOW) ↓

Loading...

Loading...