Programming technology functions (cycles)

9.1 Drilling

Turning

322 Operating Manual, 01/2015, 6FC5398-8CP40-5BA2

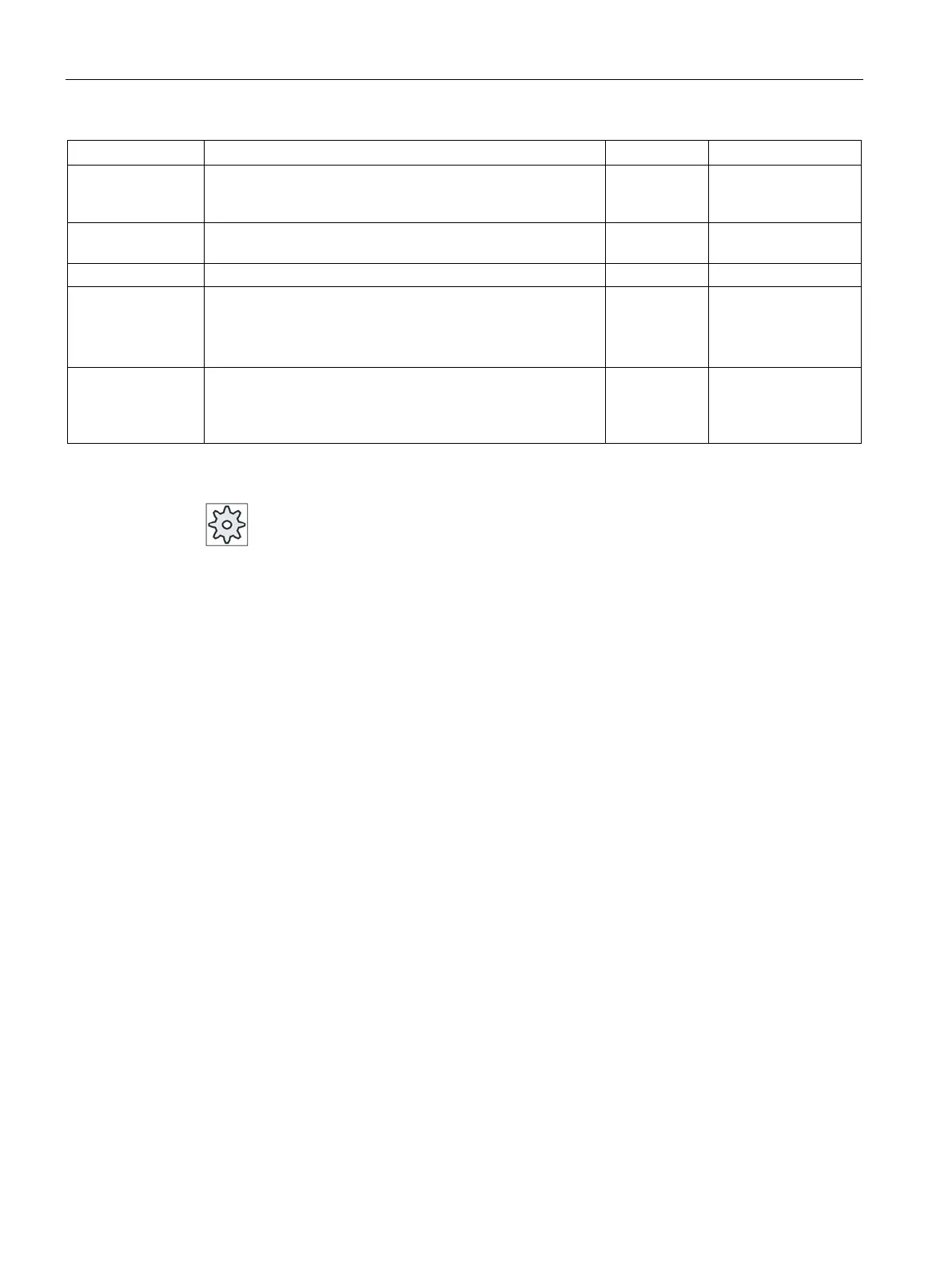

DT - (only for

through drilling

Dwell time at final depth in seconds 0.6 s

Retraction Retraction to pilot hole depth or retraction plane Pilot hole

Retraction in rapid traverse

Direction of spindle

rotation during

retraction

M5

SR (only for se-

lected spindle

direction of rota-

Spindle speed for retraction referred to the drilling speed 10 %

Please refer to the machine manufacturer's specifications.

Tapping (CYCLE84, 840)

Function

You can machine an internal thread with the "tapping" cycle.

The tool moves to the safety clearance with the active speed and rapid traverse. The spindle

stops, spindle and feedrate are synchronized. The tool is then inserted in the workpiece with

the programmed speed (dependent on %S).

You can choose between drilling in one cut, chipbreaking or retraction from the workpiece for

swarf removal.

Depending on the selection in the "Compensating chuck mode" field, alternatively the

following cycle calls are generated:

● With compensating chuck: CYCLE840

● Without compensating chuck: CYCLE84

When tapping with compensating chuck, the thread is produced in one cut. CYCLE84

enables tapping to be performed in several cuts if the spindle is equipped with a measuring

system.

Loading...

Loading...