Programming technology functions (cycles)

9.2 Rotate

Turning

382 Operating Manual, 01/2015, 6FC5398-8CP40-5BA2

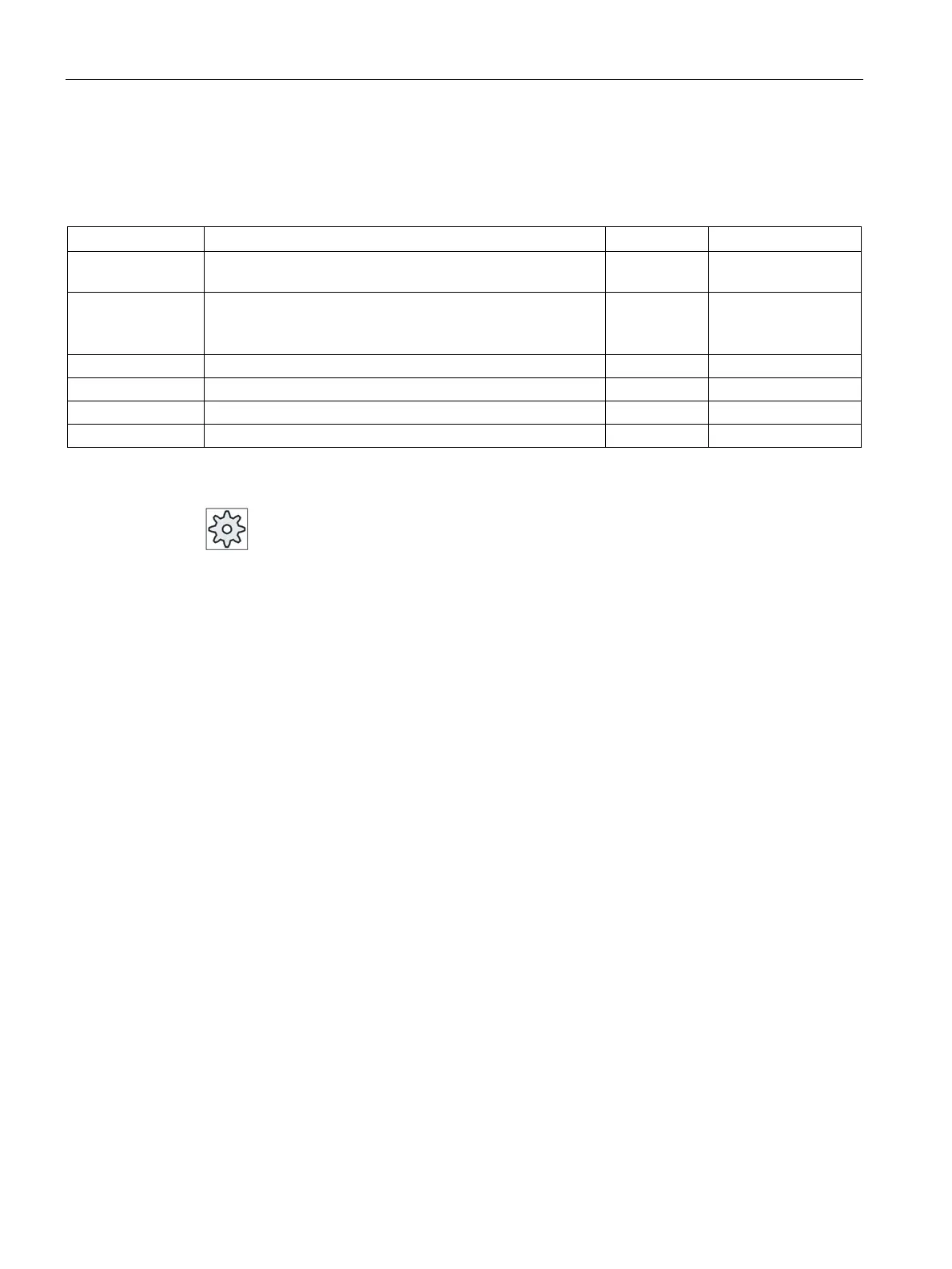

The following parameters are hidden. They are pre-assigned fixed values or values that can

be adjusted using setting data.

PL Machining plane

G Change in thread pitch per revolution – (only for P = mm/rev

or in/rev):

Without change in thread pitch

0

Initial plunge depth for reworking the threads

VR Return distance 2 mm x

Please refer to the machine manufacturer'

s specifications.

Thread chain (CYCLE98)

Function

With this cycle, you can produce several concatenated cylindrical or tapered threads with a

constant pitch in longitudinal and face machining, all of which can have different thread

pitches.

There may be single or multiple threads. With multiple threads, the individual thread turns

are machined one after the other.

You define a right or left-hand thread by the direction of spindle rotation and the feed

direction.

The infeed is performed automatically with a constant infeed depth or constant cutting cross-

section.

● With a constant infeed depth, the cutting cross-section increases from cut to cut. The

finishing allowance is machined in one cut after roughing.

A constant infeed depth can produce better cutting conditions at small thread depths.

● With a constant cutting cross-section, the cutting pressure remains constant over all

roughing cuts and the infeed depth is reduced.

The feedrate override has no effect during traversing blocks with thread. The spindle

override must not be changed during the thread machining.

Loading...

Loading...