Tool management

12.7 Tool data OEM

Turning

700 Operating Manual, 01/2015, 6FC5398-8CP40-5BA2

You have the option of configuring the list according to your requirements.

Depending on the machine configuration, grinding-specific parameters are displayed in the

list with OEM tool data.

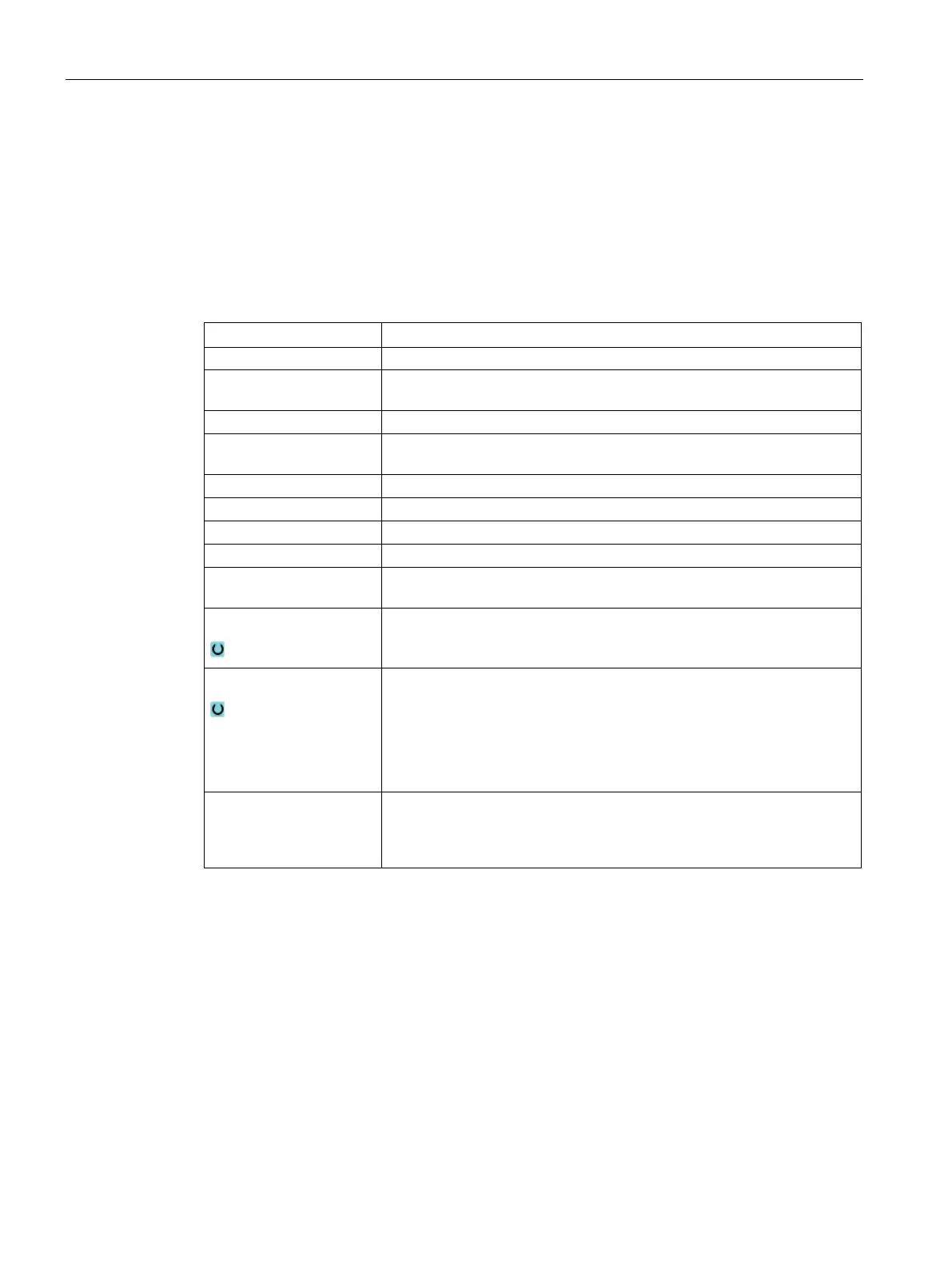

Grinding tool-specific parameters

Limit value for the radius of the grinding wheel to monitor the geometry.

Actual radius Displays the sum of the geometry value, wear value and, if set, the base

Limit value for the width of the grinding wheel to monitor the geometry.

Actual width The width of the grinding wheel measured, for example, after the dress-

Maximum peripheral velocity

Monitoring geometry and speed

Tool base dimension Defines whether the base dimension is used when calculating the SUG

and when monitoring the minimum wheel radius.

Spindle number

Number of programmed spindle (e.g. grinding wheel peripheral velocity)

and spindle to be monitored (e.g. wheel radius and width).

Param. rad.calc.

Selects the parameter to calculate the radius

• Length X

• Length Y

• Length Z

• Radius

Chaining rule This parameter defines which tool parameters of tool cutting edge 2 (D2)

and tool cutting edge 1 (D1) have to be chained to one another. When

the value of a chained parameter is modified, then the other cutting edge

is automatically used when chaining the parameter.

You can find more information on grinding tools in the following manual:

Function Manual, Extended Functions W4: Grinding-specific tool offset and monitoring

functions / SINUMERIK 840D sl

Refer to the following document for more information on configuring OEM tool data:

Commissioning Manual SINUMERIK Operate (IM9) / SINUMERIK 840D sl

Loading...

Loading...