Programming technology functions (cycles)

9.2 Rotate

Turning

Operating Manual, 01/2015, 6FC5398-8CP40-5BA2

371

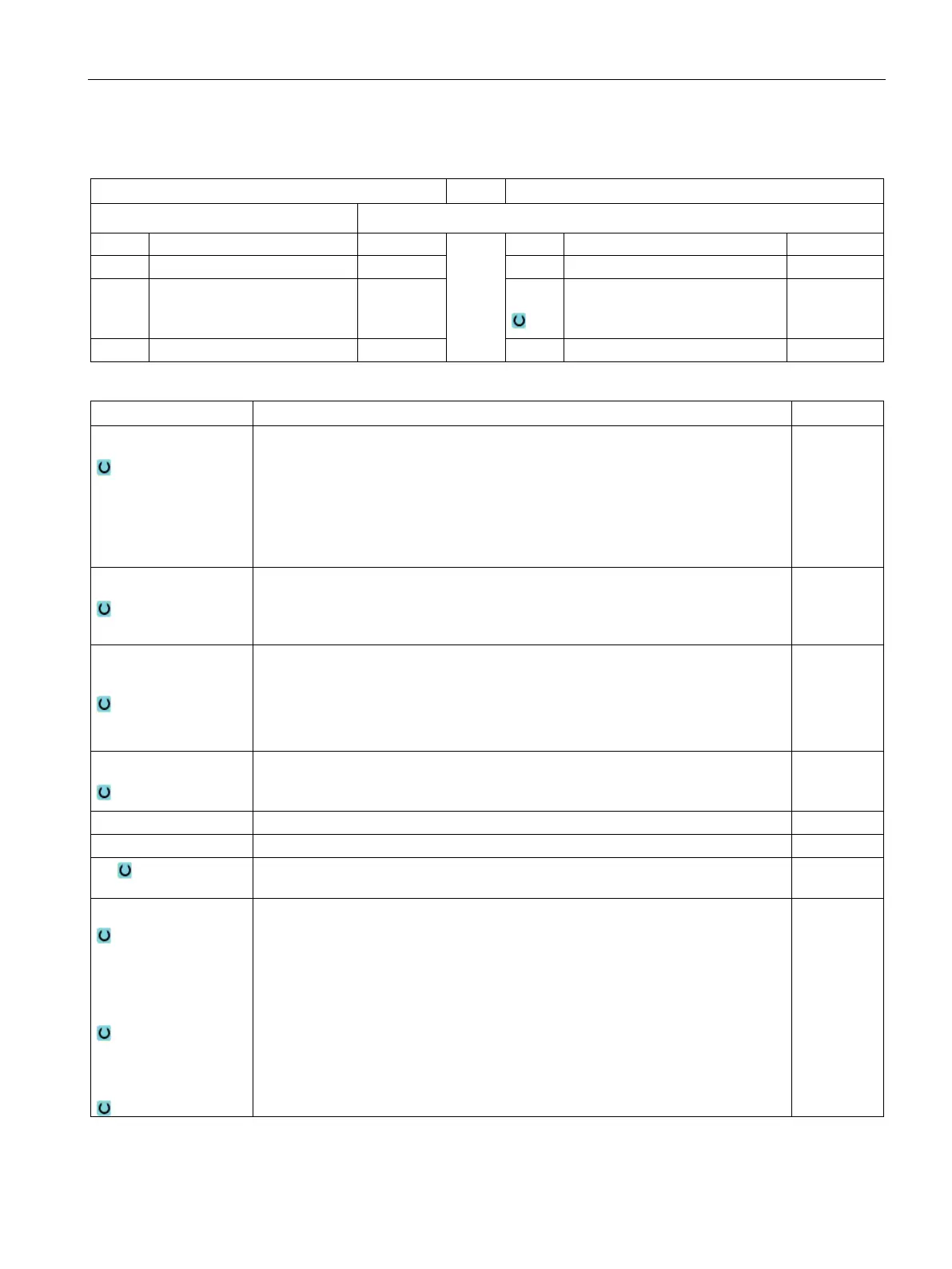

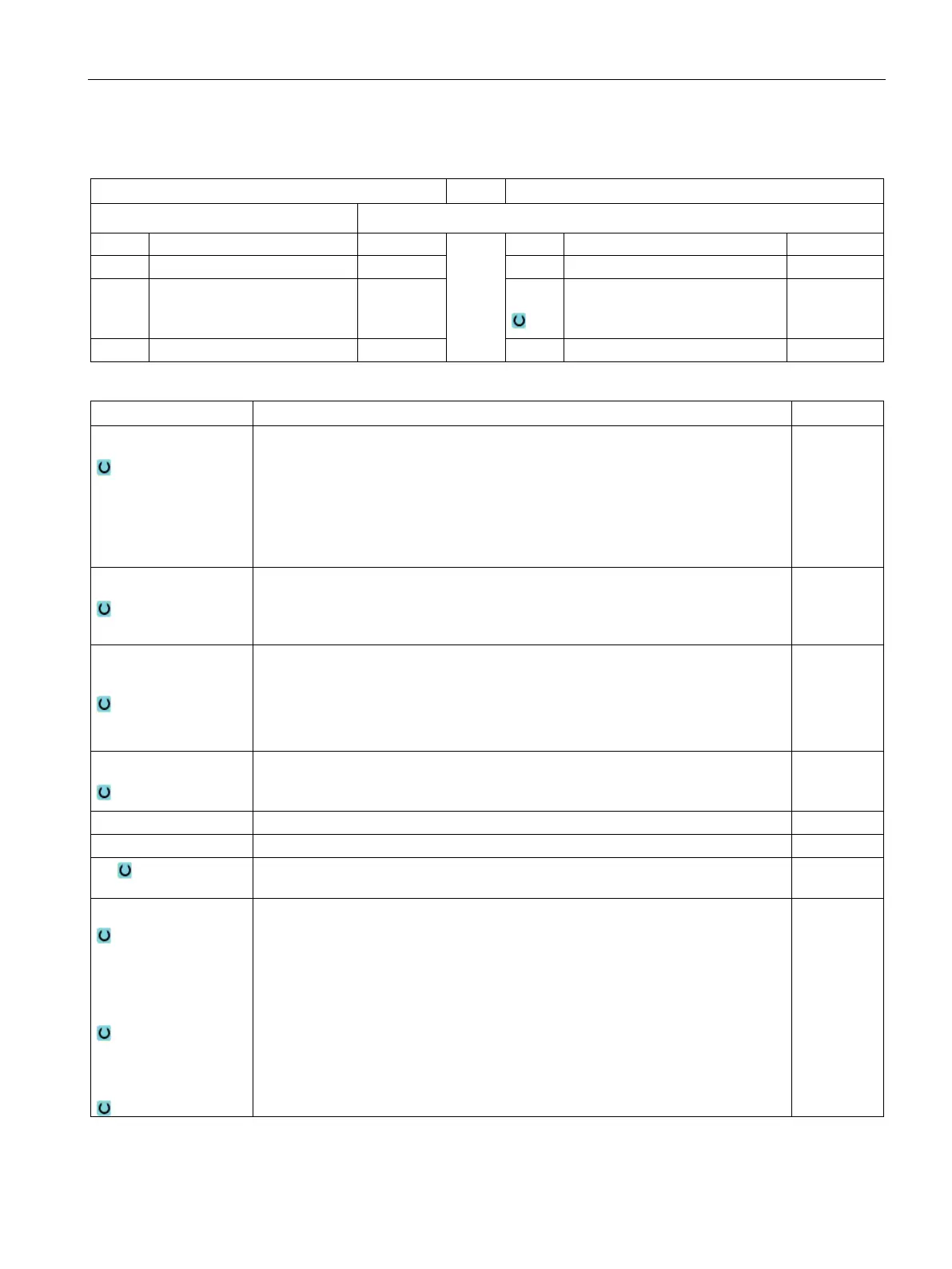

Parameter "Longitudinal thread" in the "Input simple" mode

G code program parameters

ShopTurn program parameters

Input

• simple

S / V

Spindle speed or constant cut-

ting rate

rpm

m/min

P

Select the thread pitch / turns for table "Without" or specify the thread pitch/turns

corresponding to the selection in the thread table:

• Thread pitch in mm/revolution

• Thread pitch in inch/revolution

• Thread turns per inch

• Thread pitch in MODULUS

mm/rev

in/rev

turns/"

MODULUS

Machining

• ∇ (roughing)

• ∇∇∇ (finishing)

• ∇ + ∇∇∇ (roughing and finishing)

Infeed (only for ∇ and ∇

+ ∇∇∇)

• Linear:

Infeed with constant cutting depth

• Degressive:

Infeed with constant cutting cross-section

Thread

• Internal thread

• External thread

Reference point X from thread table ∅ (abs)

Z1 End point of the thread (abs) or thread length (inc)

Incremental dimensions: The sign is also evaluated.

mm

LW

or

LW2

or

LW2 = LR

Thread advance (inc)

The starting point for the thread is the reference point (X0, Z0) brought forward by

the thread advance W. The thread advance can be used if you wish to begin the

individual cuts slightly earlier in order to also produce a precise start of thread.

Thread run-in (inc)

The thread run-

in can be used if you cannot approach the thread from the side and

instead have to insert the tool into the material (e.g. lubrication groove on a shaft).

Thread run-in = thread run-out (inc)

mm

mm

mm

Loading...

Loading...