Programming technology functions (cycles)

9.2 Rotate

Turning

Operating Manual, 01/2015, 6FC5398-8CP40-5BA2

375

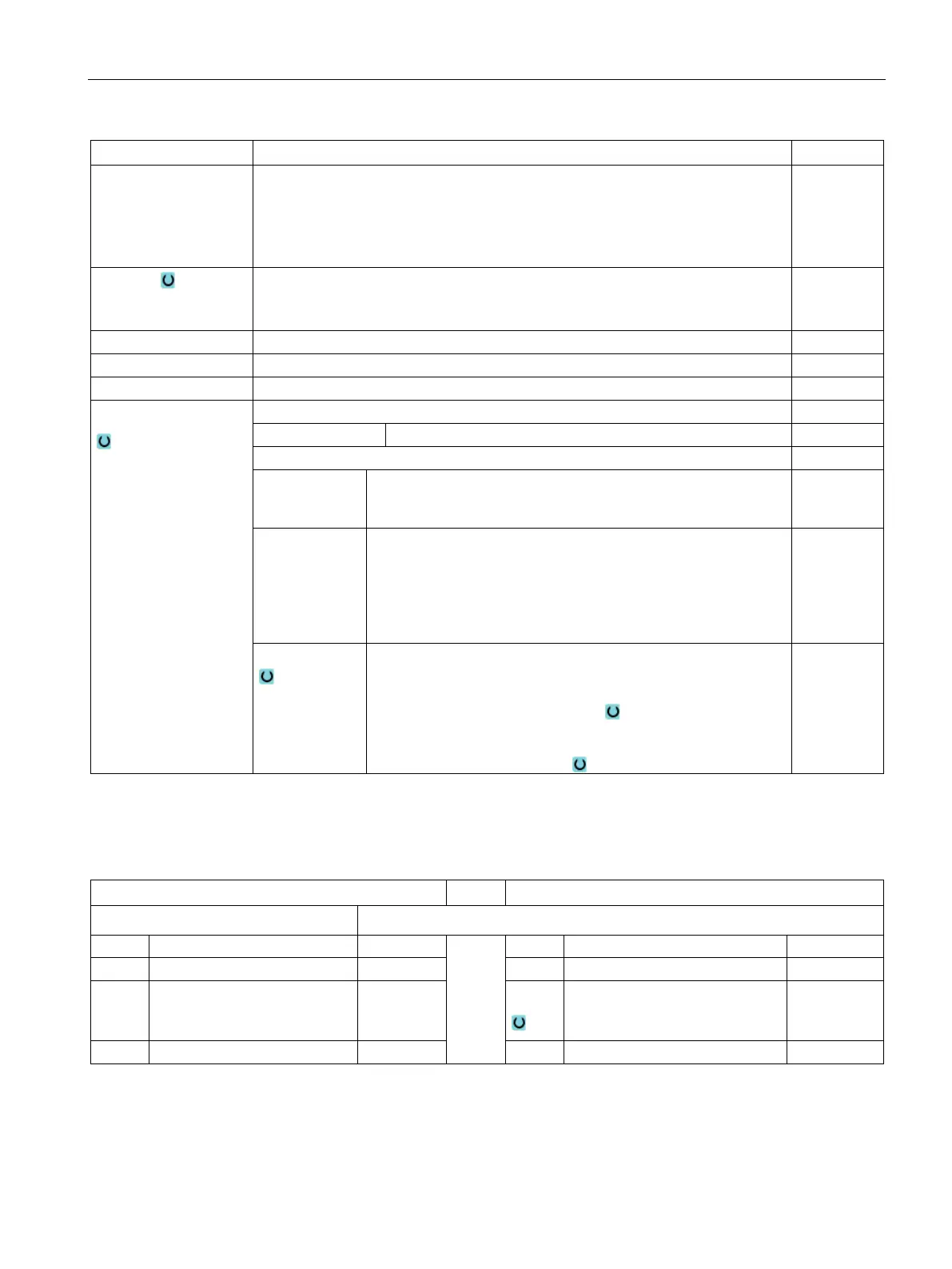

D0 Initial plunge depth – (only for ∇ and ∇ + ∇∇∇ under "Manual Machine")

If you want to rework some threads, input the initial plunge depth D0 (inc.). This is

the depth that was reached during a previous machining.

By inputting the plunge depth, you avoid unnecessary idle cuts when reworking

mm

D1 or ND

(only for ∇ and

First infeed depth or number of roughing cuts

The respective value is displayed when you switch between the number of rough-

ing cuts and the first infeed.

mm

Finishing allowance in X and Z – (only for ∇ and ∇ + ∇∇∇)

Number of noncuts - (only for ∇∇∇ and ∇ + ∇∇∇)

Multiple threads

N Number of thread turns

The thread turns are distributed evenly across the periphery of

the turned part; the 1st thread turn is always located at 0°.

DA Thread changeover depth (inc)

First machine all thread turns sequentially to thread changeover

depth DA, then machine all thread turns sequentially to depth 2 ·

DA, etc. until the final depth is reached.

DA = 0: Thread changeover depth is not taken into account, i.e.

finish machining each thread before starting the next thread.

mm

Machining:

• Complete, or

• from turn N1

N1 (1...4) start thread N1 = 1...N

or

• only thread NX

NX (1...4) 1 from N threads

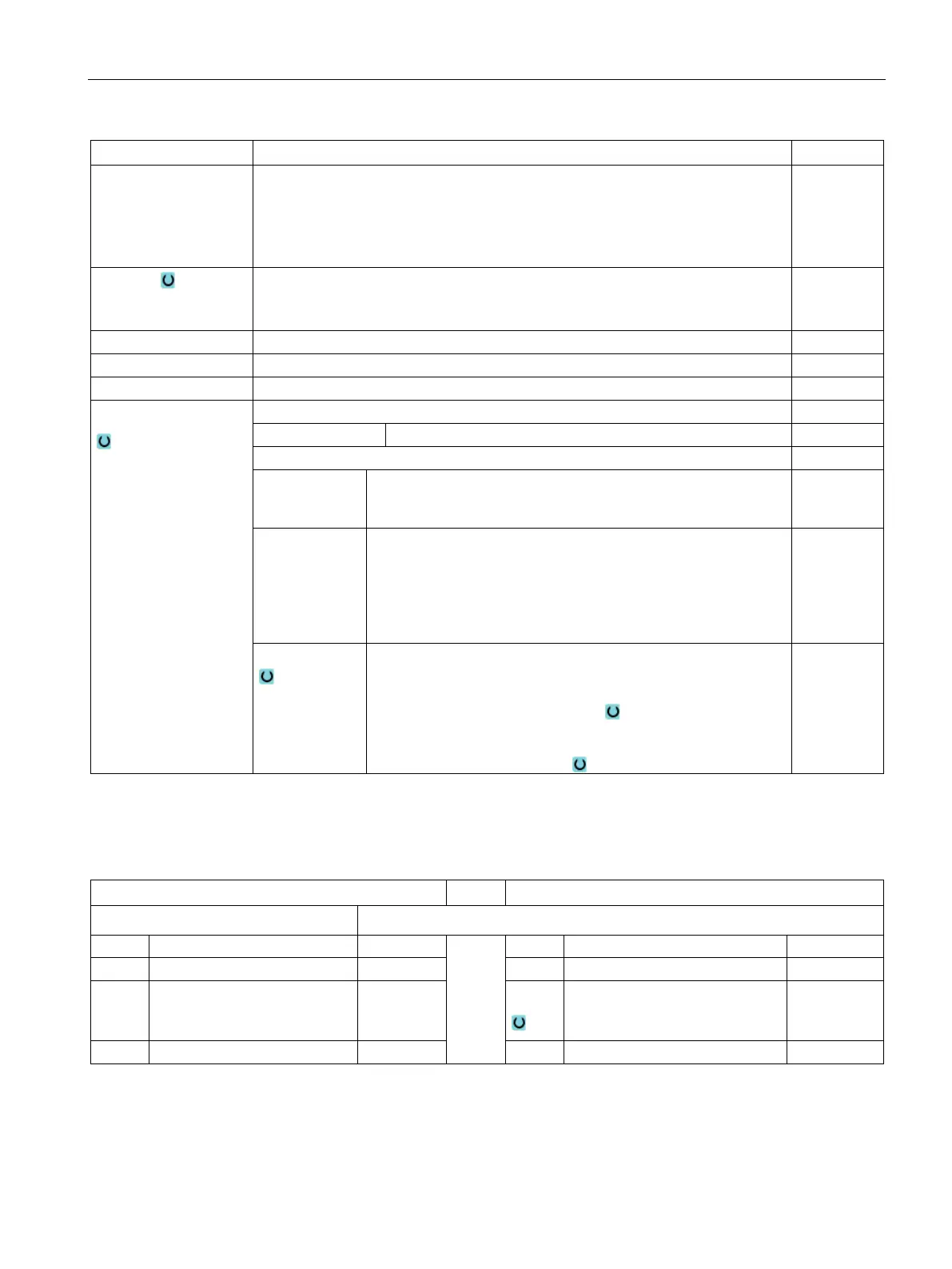

Parameter "Tapered thread" in the "Input simple" mode

G code program parameters

ShopTurn program parameters

Input

• simple

S / V

Spindle speed or constant cut-

ting rate

rpm

m/min

Loading...

Loading...