Programming technology functions (cycles)

9.2 Rotate

Turning

378 Operating Manual, 01/2015, 6FC5398-8CP40-5BA2

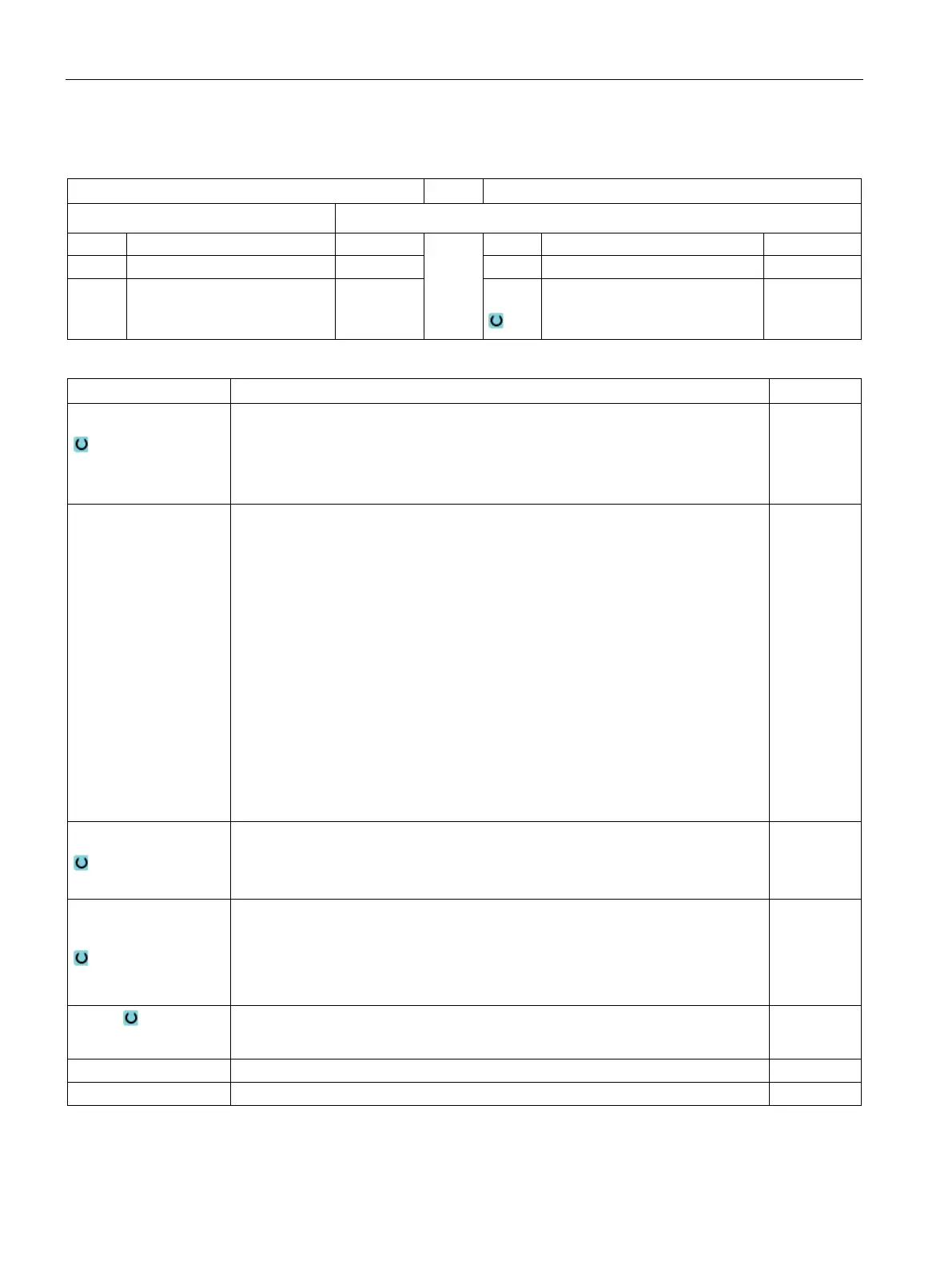

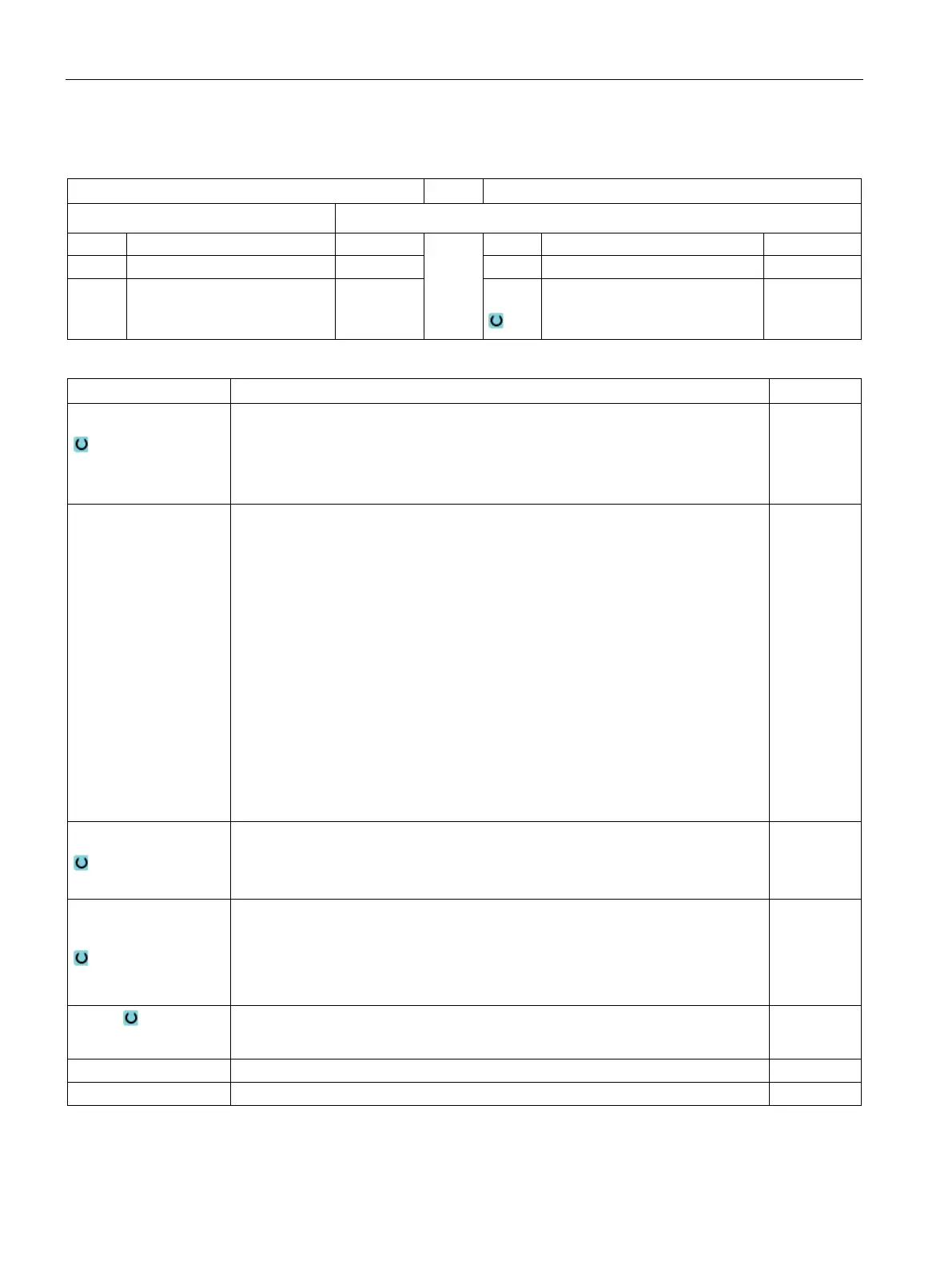

Parameter "Face thread" in the "Input complete" mode

G-code program parameters

Parameters, ShopTurn program

Input

• Complete

S / V

Spindle speed or constant cut-

ting rate

rpm

m/min

P

• Thread pitch in mm/revolution

• Thread pitch in inch/revolution

• Thread turns per inch

• Thread pitch in MODULUS

mm/rev

in/rev

turns/"

MODULUS

G Change in thread pitch per revolution - (only for P = mm/rev or in/rev)

G = 0: The thread pitch P does not change.

G > 0: The thread pitch P increases by the value G per revolution.

G < 0: The thread pitch P decreases by the value G per revolution.

If the start and end pitch of the thread are known, the pitch change to be pro-

grammed can be calculated as follows:

|P

e

2

- P

2

|

G = ----------------- [mm/rev2]

2 * Z

1

The meanings are as follows:

P

e

: End pitch of thread [mm/rev]

P: Start pitch of thread [mm/rev]

Z

1

: Thread length [mm]

A larger pitch results in a larger distance between the thread turns on the work-

mm/rev

2

Machining

• ∇ (roughing)

• ∇∇∇ (finishing)

• ∇ + ∇∇∇ (roughing and finishing)

Infeed (only for ∇ and ∇

+ ∇∇∇)

• Linear:

Infeed with constant cutting depth

• Degressive:

Infeed with constant cutting cross-section

Thread

• Internal thread

• External thread

Reference point X ∅ (abs, always diameter)

Loading...

Loading...