Programming technology functions (cycles)

9.3 Contour turning

Turning

410 Operating Manual, 01/2015, 6FC5398-8CP40-5BA2

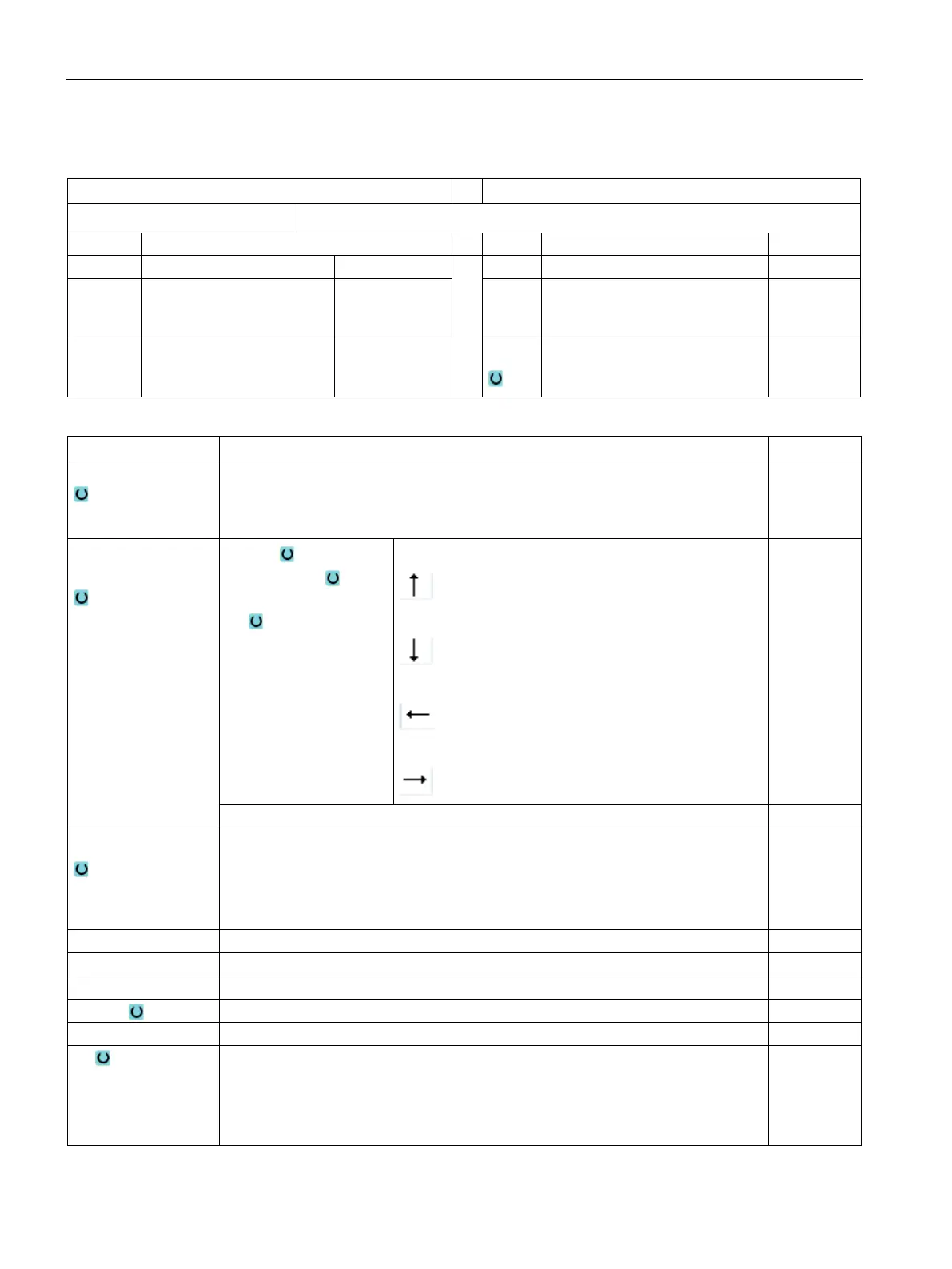

Parameters in the "Input simple" mode

G code program parameters

ShopTurn program parameters

Input

• simple

Name of the program to be generated

RP Retraction plane – (only for

machining direction, longi-

tudinal, inner)

mm F Feedrate mm/rev

F Feedrate * S / V

Spindle speed or constant cutting

rate

m/min

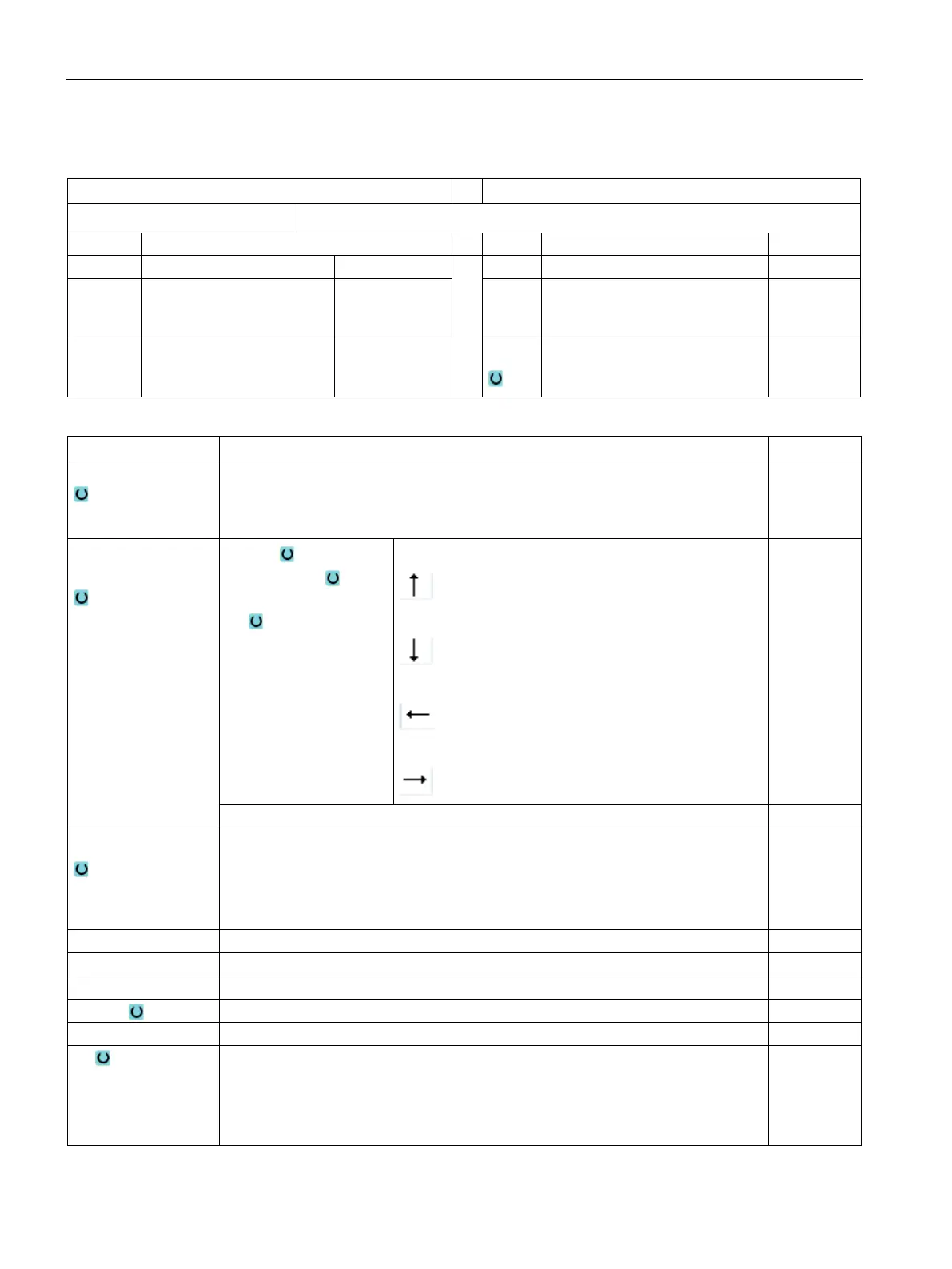

Machining

• ∇ (roughing)

• ∇∇∇ (finishing)

• ∇+∇∇∇ (complete machining)

Machining

direction

• face

• longitudinal

• parallel to the contour

• from inside to outside

• from outside to inside

• from end face to rear side

• from rear side to end face

The machining direction depends on the stock removal direction and choice of tool.

Position

• front

• back

• inside

• outside

Maximum depth infeed - (only for ∇)

Maximum depth infeed - (only for parallel to the contour, as an alternative to D)

Maximum depth infeed - (only for position parallel to the contour and UX)

Finishing allowance in X or finishing allowance in X and Z – (only for ∇)

Finishing allowance in Z – (only for UX)

BL Blank description (only for ∇)

• Cylinder (described using XD, ZD)

• Allowance (XD and ZD on the finished part contour)

• Contour (additional CYCLE62 call with blank contour – e.g. cast iron mold)

Loading...

Loading...