Programming technology functions (cycles)

9.4 Milling

Turning

Operating Manual, 01/2015, 6FC5398-8CP40-5BA2

455

For simple machining operations, you have the option to reduce the wide variety of

parameters to the most important parameters using the "Input" selection field. In this "Input

simple" mode, the hidden parameters are allocated a fixed value that cannot be adjusted.

Various defined values can be pre

-assigned using setting data.

Please refer to the machine manufacturer's specifications.

If the workpiece programming requires it, you can display and change all of the parameters

using "Input complete".

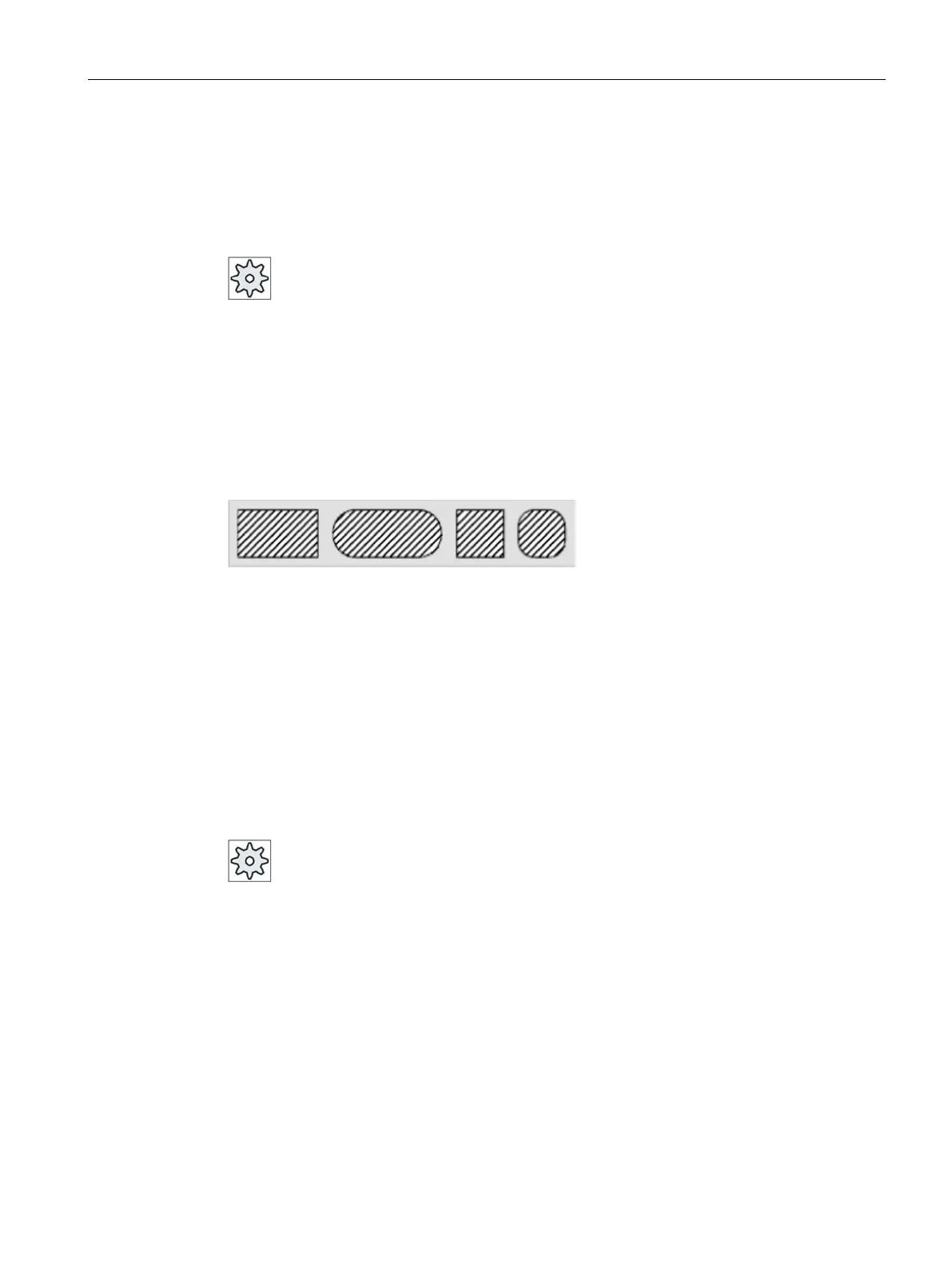

You can mill various rectangular spigots with the "Rectangular spigot" cycle.

You can select from the following shapes with or without a corner radius:

In addition to the required rectangular spigot, you must also define a blank spigot, i.e. the

outer limits of the material. The tool moves at rapid traverse outside this area. The blank

spigot must not overlap adjacent blank spigots and is automatically placed by the cycle in a

central position on the finished spigot.

The spigot is machined using only one infeed. If you want to machine the spigot using

multiple infeeds, you must program the "Rectangular spigot" function several times, with a

continually decreasing finishing allowance.

For ShopTurn, the "Clamp spindle" function can be set up by the machine manufacturer.

Please refer to the machi

ne manufacturer's specifications.

Loading...

Loading...