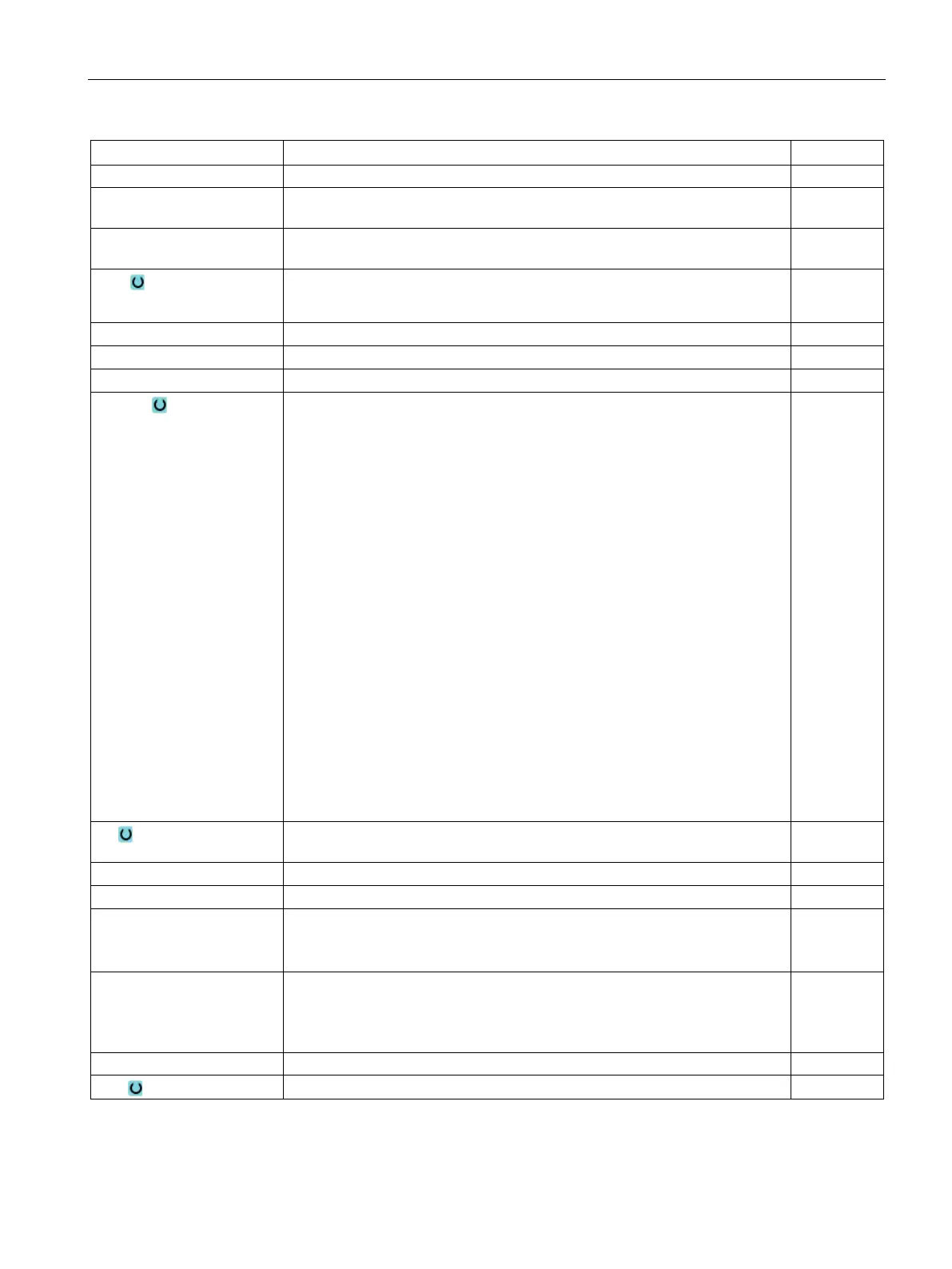

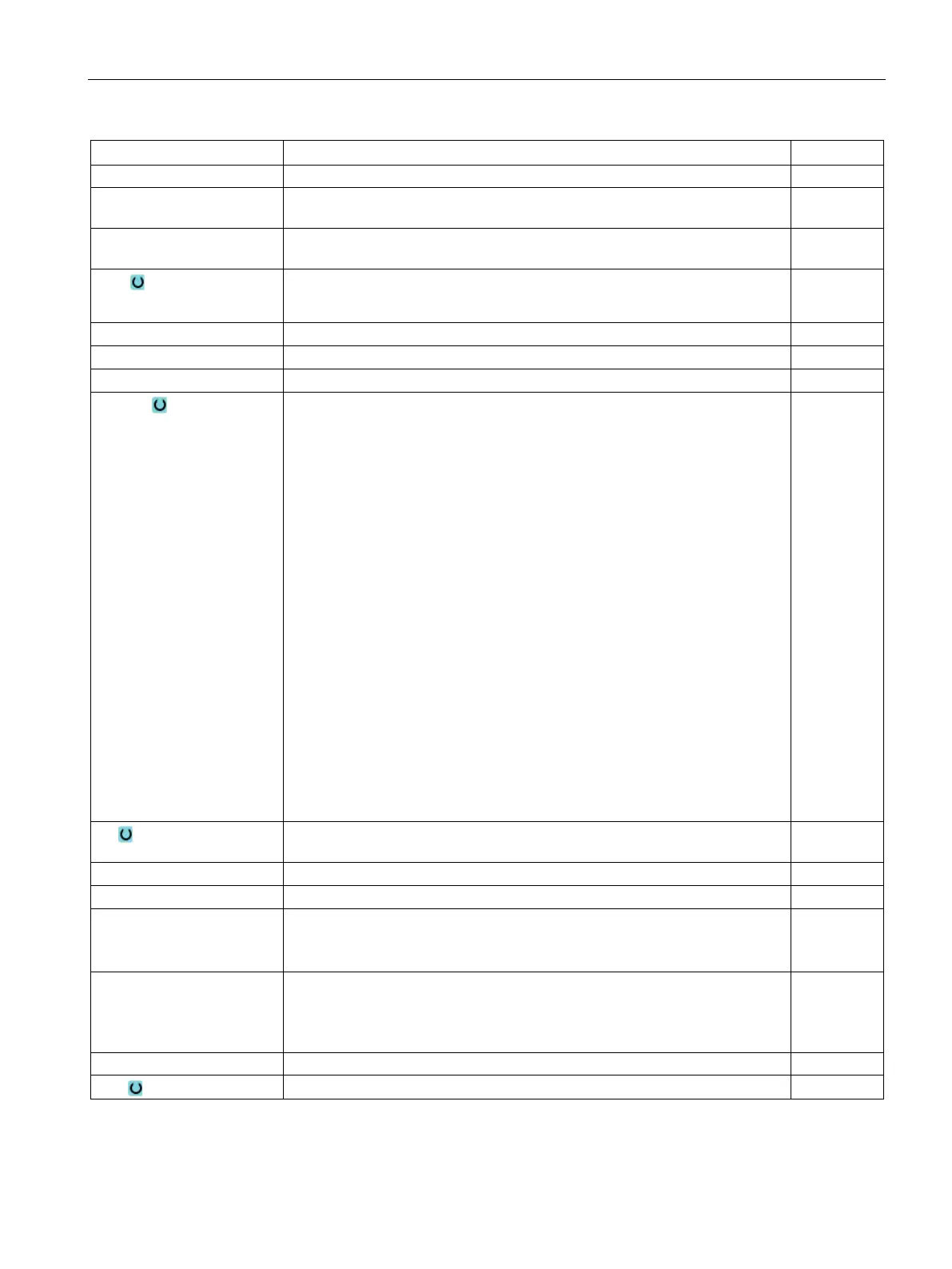

Programming technology functions (cycles)

9.5 Contour milling

Turning

Operating Manual, 01/2015, 6FC5398-8CP40-5BA2

543

Pocket depth (abs) or depth referred to Z0 (inc)

CP

(only for ShopTurn)

Positioning angle for machining area - (only for machining surface, face Y) Degrees

C0

Positioning angle for machining area - (only for machining surface, peripheral

Degrees

DXY

• Maximum plane infeed

• Maximum plane infeed as a percentage of the milling cutter diameter

mm

%

Finishing allowance, plane

Finishing allowance, depth

Insertion The following insertion modes can be selected – (only for ∇, ∇∇∇ base or ∇∇∇

edge):

•

The calculated actual infeed depth is executed at the calculated position

for "automatic" starting point – or at the specified position for "manual"

starting point.

Note:

This setting can be used only if the cutter can cut across center or if the

pocket has been predrilled.

•

The cutter center point traverses along the helical path determined by the

radius and depth per revolution (helical path). If the depth for one infeed

has been reached, a full circle motion is executed to eliminate the inclined

insertion path.

•

The cutter center point oscillates back and forth along a linear path until it

reaches the depth infeed. When the depth has been reached, the path is

traversed again without depth infeed in order to eliminate the inclined in-

FZ (only for ShopTurn) Depth infeed rate – (only for vertical insertion and ∇) mm/min

Depth infeed rate – (only for vertical insertion and ∇)

Maximum pitch of helix – (for helical insertion only)

ER Radius of helix – (for helical insertion only)

The radius cannot be any larger than the milling cutter radius; otherwise,

mm

EW

:

During insertion with oscillation, the message “Ramp path too short” will ap-

pear if the tool is less than the milling cutter diameter away from the insertion

point along the ramp. If this occurs, please reduce the angle of insertion.

Degrees

Chamfer width for chamfering (inc) - (for chamfering only)

ZFS Insertion depth of tool tip (abs or inc) - (for chamfering only) mm

* Unit of feedrate as programmed before the cycle call

Loading...

Loading...