3 - 19

Chapter 3 Image Quality Troubleshooting

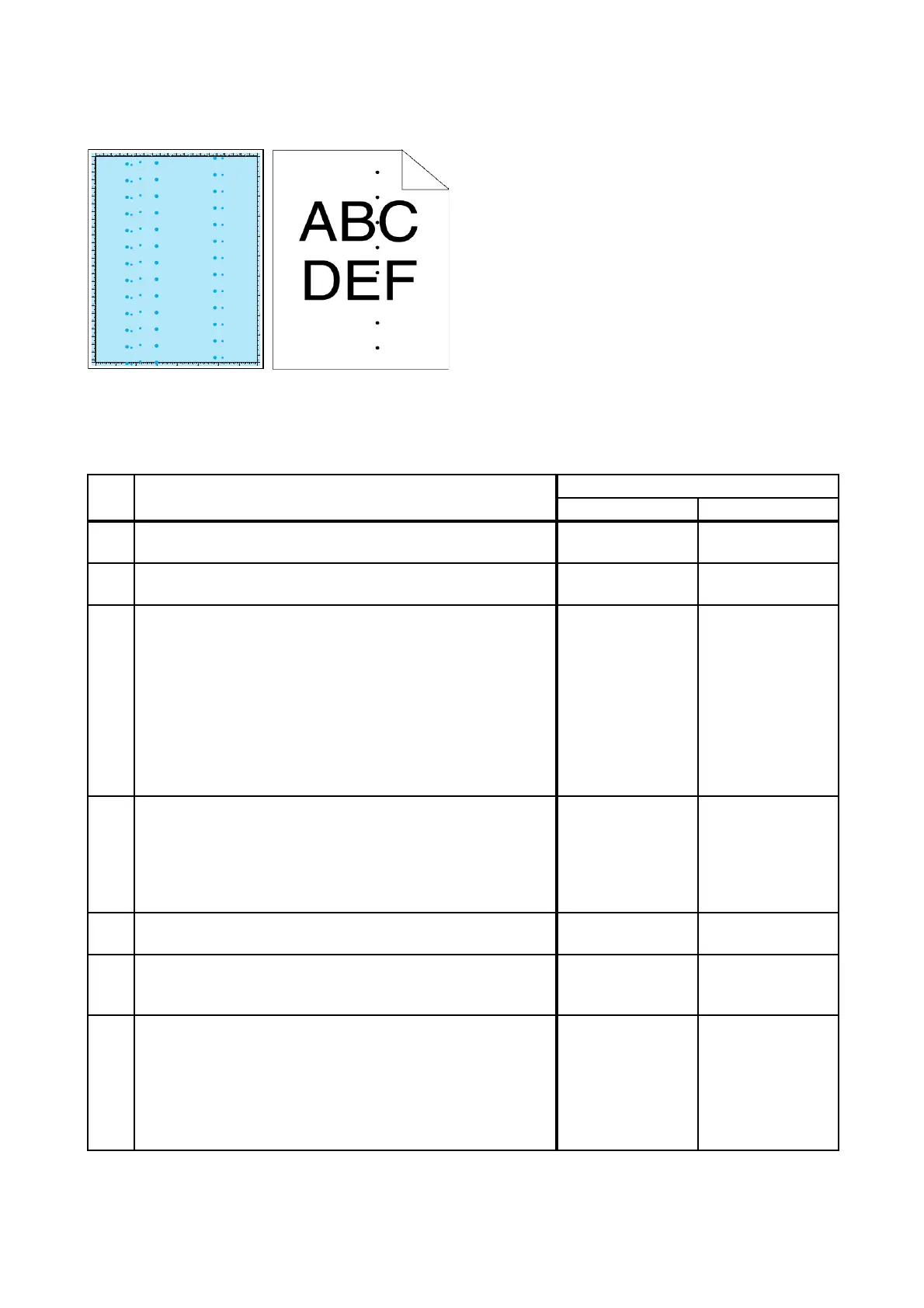

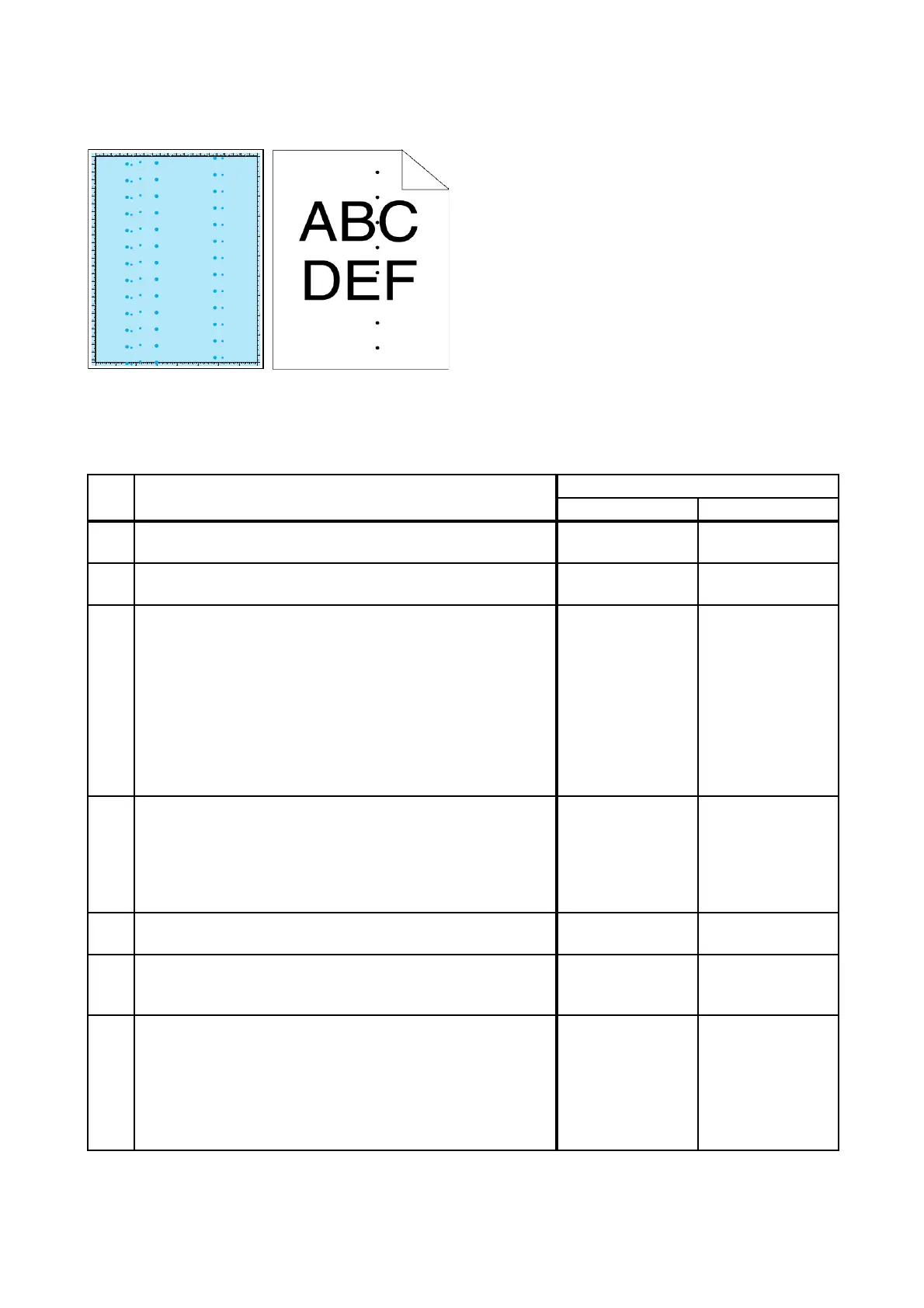

FIP-1.P7 Pitched color dots

ESS and possible causative parts

- TRANSFER ASSY (PL6.1.7)

- PHD ASSY (PL4.1.21)

- FUSING UNIT (PL6.1.1)

- IIT ASSY SUB (PL10.1.11)

Before commencing troubleshooting, check the paper transfer path. Make sure there is no foreign

materials on the transfer path, such as staples, paper clips, scraps of paper and so on.

Step Check

Remedy

Yes No

1

Checking the error mode.

Does the error occur only during copying?

Go to step 2. Go to step 4.

2

Checking the original.

Is the original color clean?

Go to step 3.

Checking the

original.

3

Checking the platen glass and ADF Feed Roller.

Are there any damages or foreign substances?

Remove the

foreign

substances or

Clean up the

Scanner.If platen

glass has been

damaged,

Replace the IIT

ASSY SUB (Refer

to REP9.5.)

Go to step 5.

4

Checking the Print.

Checked by [Test-Print] - [Contamination check] in

diagnosis.

Is the image printed correctly?

Printing data is

incorrect,then

check the printing

data which the

problem

generated.

Go to step 5.

5

Checking after cleaning Inside the Printer.

Is the image printed correctly?

End of work. Go to step 6.

6

Shake and reseat the suspected TONER CARTRIDGE (Y,

M, C, or K)

Is the image printed correctly?

End of work. Go to step 7.

7

Checking the defective parts.

Print the [Pitch Configuration Chart] in [Chart Print] in

[Diagnosis] tab of [Tool Box].

When the partial lacks of periodicity are observed, check the

defective parts by comparing the printed partial lacks with

the Pitch Chart.

Are there any partial lackes matching the chart?

Replace the

corresponding

parts.

Go to step 8.

Loading...

Loading...