3 - 38

Chapter 3 Image Quality Troubleshooting

FIP-1.P16 Wrinkled/Stained paper (Envelope Wrinkle)

.Possible causative parts

- HOLDER ASSY SEPARATOR (PL2.1.5)

- ROLL ASSY FEED (PL3.2.4)

- ROLL ASSY REGI (PL3.2.9)

- ROLL REGI METAL (PL3.2.10)

Tray is recommended for paper feeding because sheets fed via SSF is prone to

skew depending on how the sheet is placed on SSF.

Before commencing troubleshooting, check the paper transfer path. Make sure there is no foreign

materials on the transfer path, such as staples, paper clips, scraps of paper and so on.

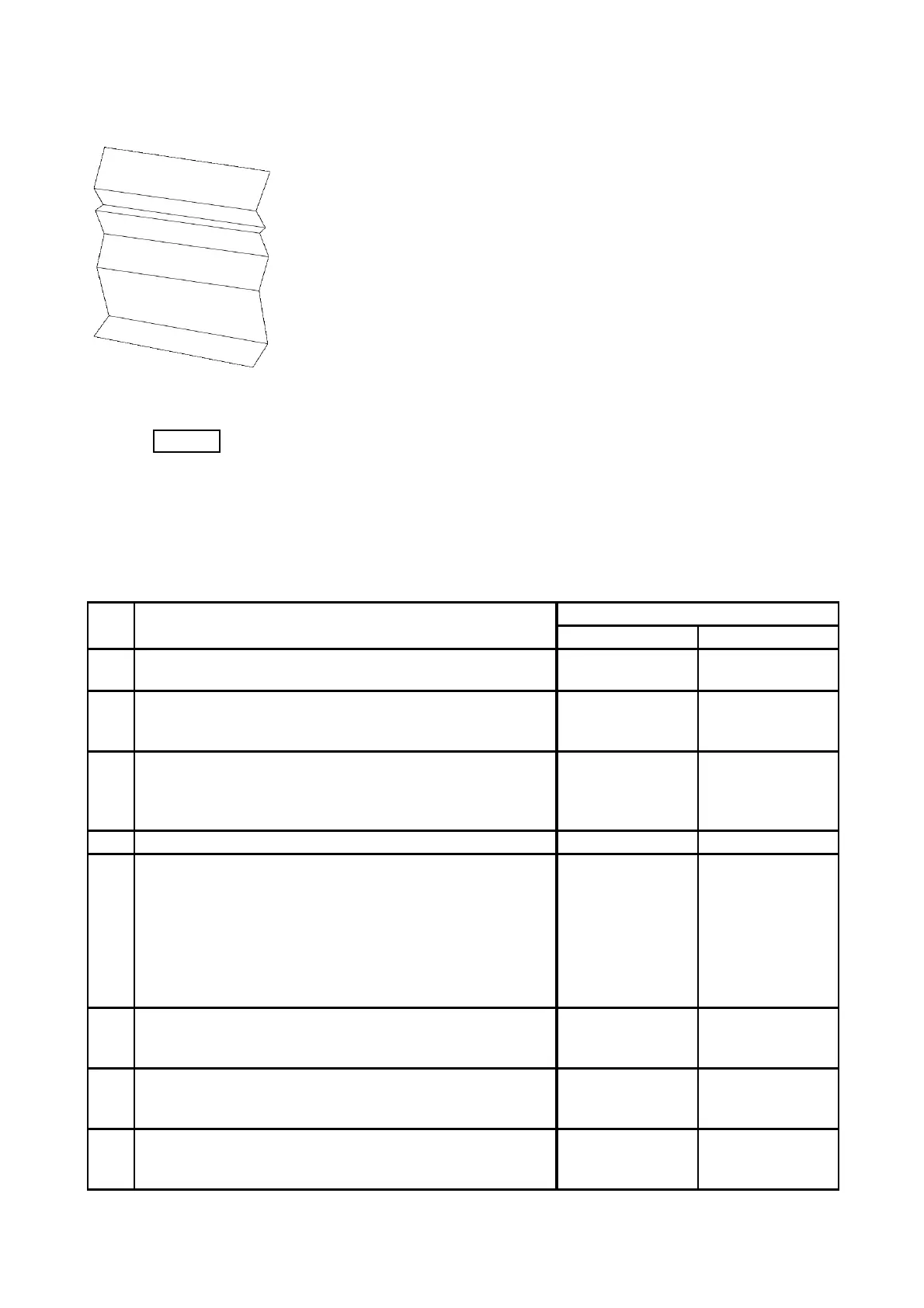

Step Check

Remedy

Yes No

1

Checking the paper feeding tray.

Is the skewed paper fed from the SSF?

Go to step 2. Go to step 6.

2

Checking the side guides setting of SSF.

Reset the side guides.

Is the image printed correctly?

End of work. Go to step 3.

3

Checking the paper path.

Are there any foreign substances on the paper path?

Remove the

foreign

substances, then

go to step 4.

Go to step 5.

4 Is the image printed correctly? End of work. Go to step 5.

5

Checking the ROLL ASSY REGI and ROLL ASSY METAL

for rotation.

Checked by [Digital Output] - [Main Motor] in [IOT Diag],

and then enter the [Digital Output] - [Regi Clutch] in [IOT

Diag].

Does the Roll Assy Regi and Roll Regi Metal rotate?

During this check, cheat the interlock switch (HARN ASSY

INTERLOCK AIO).

End of work.

Replace the ROLL

ASSY REGI and/

or ROLL REGI

METAL.

6

Checking after resetting the Paper Cassette.

Reseat the Paper Cassette.

Is the image printed correctly?

End of work. Go to step 7.

7

Checking after resetting the paper.

Reseat the paper in the Paper Cassette.

Is the image printed correctly?

End of work. Go to step 8.

8

Checking the side guides of the Paper Cassette.

Reset the side guides.

Is the image printed correctly?

End of work. Go to step 9.

Loading...

Loading...