Machining the workpiece

4.12 Displaying G functions and auxiliary functions

Turning

158 Operating Manual, 03/2013, 6FC5398-8CP40-3BA1

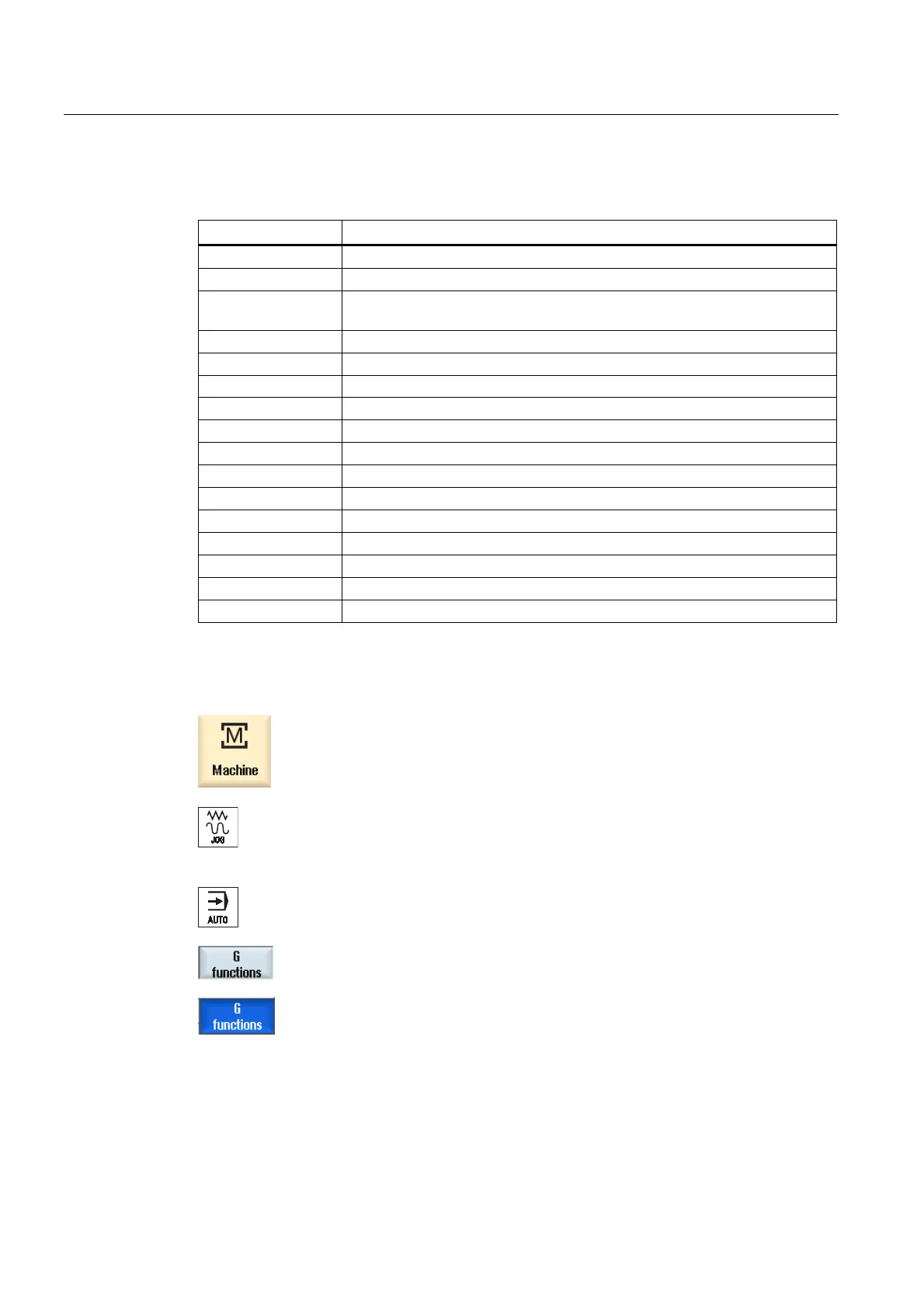

G groups displayed by default (ISO code)

Group Meaning

G group 1 Modally active motion commands (e.g. G0, G1, G2, G3)

G group 2 Non-modally active motion commands, dwell time (e.g. G4, G74, G75)

G group 3 Programmable offsets, working area limitations and pole programming (e.g.

TRANS, ROT, G25, G110)

G group 6 Plane selection (e.g. G17, G18)

G group 7 Tool radius compensation (e.g. G40, G42)

G group 8 Settable work offset (e.g. G54, G57, G500)

G group 9 Offset suppression (e.g. SUPA, G53)

G group 10 Exact stop - continuous-path mode (e.g. G60, G641)

G group 13 Workpiece dimensioning inches/metric (e.g. G70, G700)

G group 14 Workpiece dimensioning absolute/incremental (G90)

G group 15 Feedrate type (e.g. G93, G961, G972)

G group 16 Feedrate override on inside and outside curvature (e.g. CFC)

G group 21 Acceleration profile (e.g. SOFT, DRIVE)

G group 22 Tool offset types (e.g. CUT2D, CUT2DF)

G group 29 Radius/diameter programming (e.g. DIAMOF, DIAMCYCOF)

G group 30 Compressor ON/OFF (e.g. COMPOF)

Procedure

1. Select the "Machine" operating area.

...

2. Press the <JOG>, <MDA> or <AUTO> key.

3. Press the "G functions" softkey.

The "G Functions" window is opened.

4. Press the "G functions" softkey again to hide the window.

The G groups selection displayed in the "G Functions" window may differ.

Loading...

Loading...