Creating a ShopTurn program

7.18 Example: Standard machining

Turning

272 Operating Manual, 03/2013, 6FC5398-8CP40-3BA1

L 23

R 8

α0 4Degrees

Z1 5inc

DXY 50%

DZ 3

UXY 0.1mm

UZ 0

Insertion Vertical

FZ 0.015mm/tooth

4. Press the "Accept" softkey.

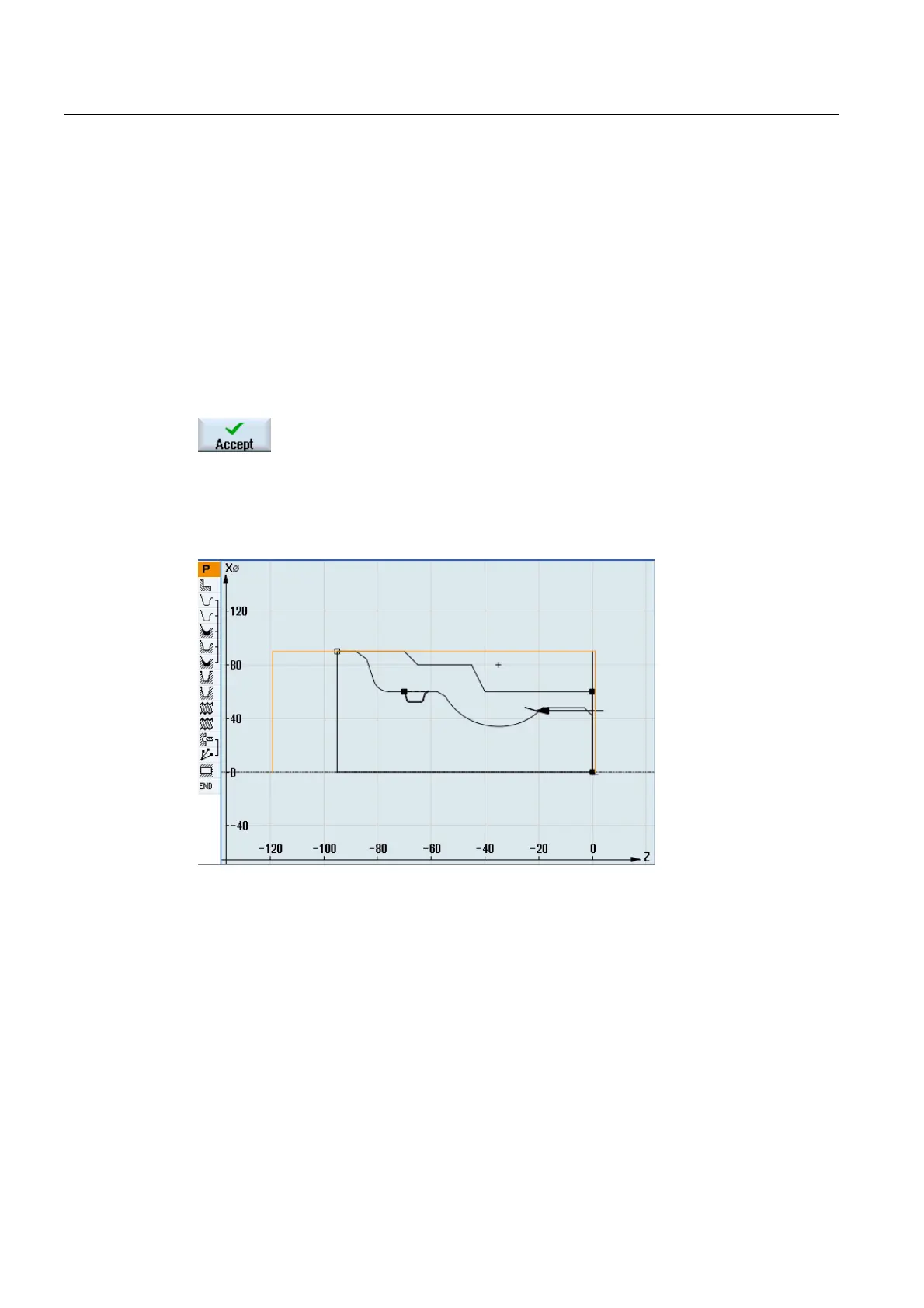

7.18.3 Results/simulation test

Figure 7-10 Programming graphics

Loading...

Loading...