Programming technology functions (cycles)

8.3 Contour turning

Turning

352 Operating Manual, 03/2013, 6FC5398-8CP40-3BA1

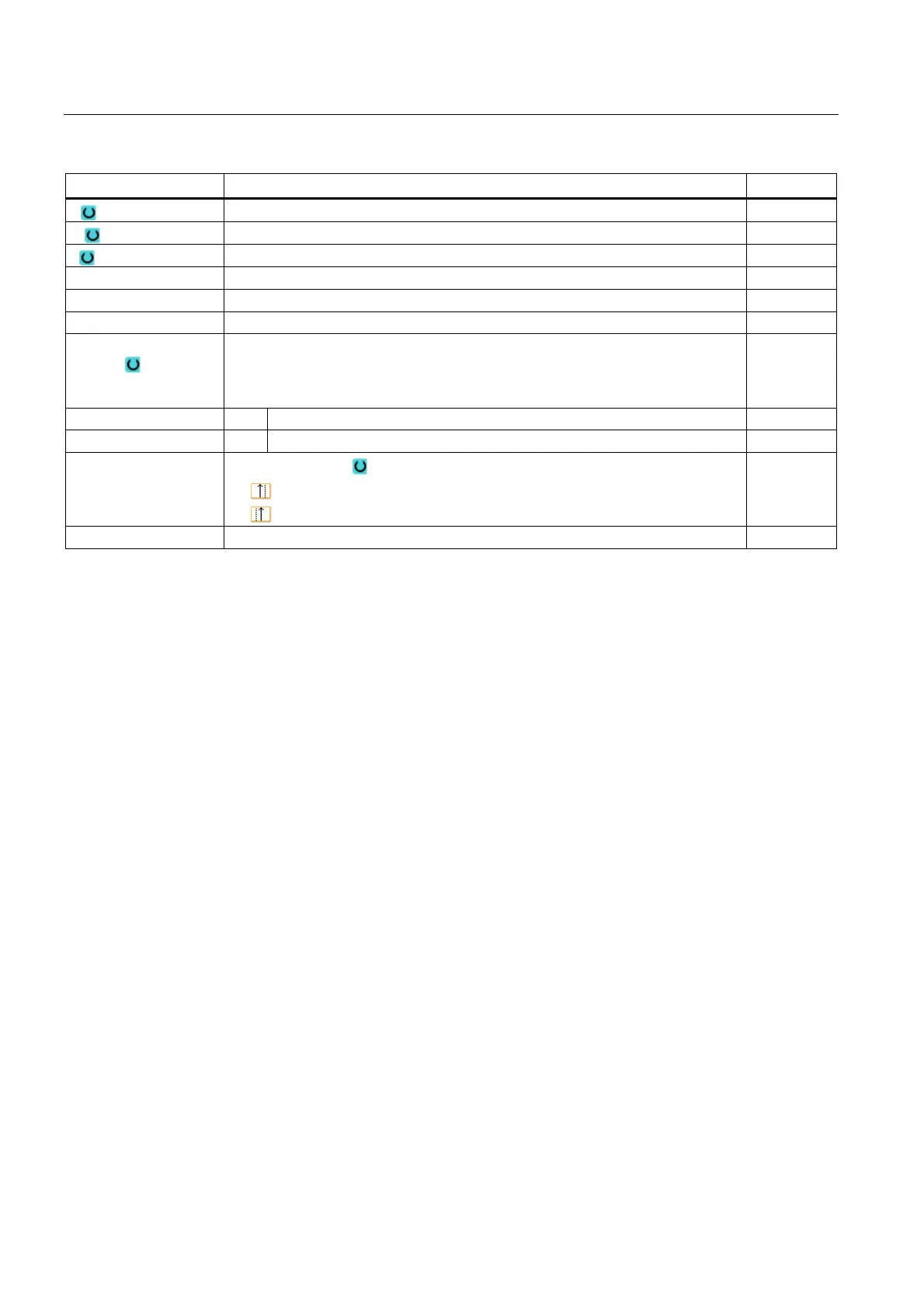

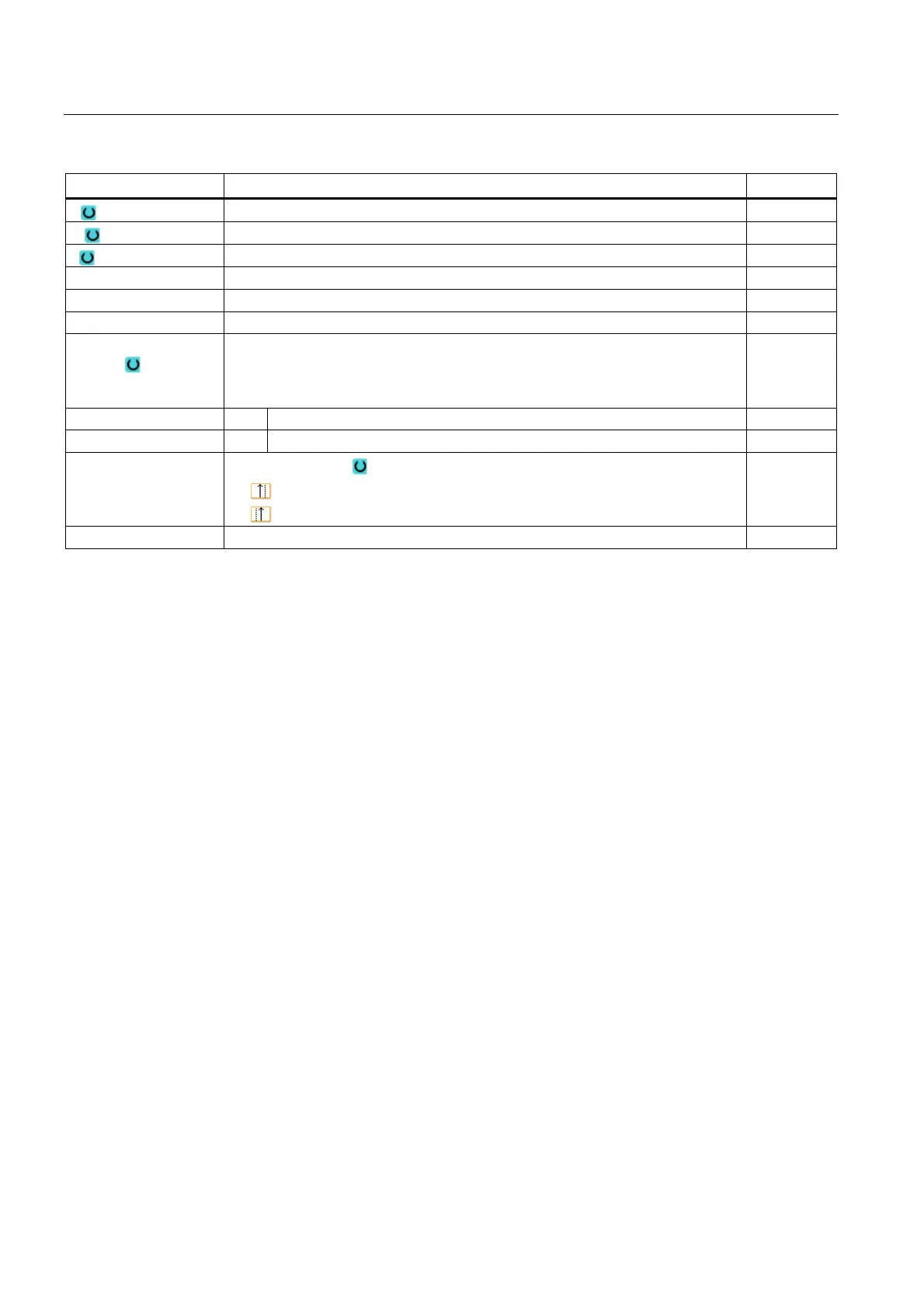

Parameters Description Unit

X End point X ∅ (abs) or end point X (inc) mm

K Circle center point K (abs or inc) mm

I Circle center point I ∅ (abs or circle center point I (inc) mm

α1 Starting angle to Z axis Degrees

β1 End angle to Z axis Degrees

β2 Opening angle Degrees

Transition to next

element

Type of transition

• Radius

• Chamfer

Radius R Transition to following element - radius mm

Chamfer FS Transition to following element - chamfer mm

CA Grinding allowance

• Grinding allowance to right of contour

•

Grinding allowance to left of contour

mm

Additional commands Additional G code commands

Contour element "End"

The data for the transition at the contour end of the previous contour element is displayed in

the "End" parameter screen.

The values cannot be edited.

8.3.5 Entering the master dimension

If you would like to finish your workpiece to an exact fit, you can input the master dimension

directly into the parameter screen form during programming.

Specify the master dimension as follows:

F<Diameter/Length> <Tolerance class> <Tolerance quality>

"F" identifies that a master dimension follows, i.e. in this case, a hole.

Example: F20h7

Possible tolerance classes:

A, B, C, D, E, F, G, H, J, T, U, V, X, Y, Z

Upper-case characters: Holes

Lower case letters: Shafts

Possible tolerance qualities:

1 to 18, if they are not restricted by DIN standard 7150.

Loading...

Loading...