Creating a G code program

6.3 Program structure

Turning

Operating Manual, 03/2013, 6FC5398-8CP40-3BA1

201

6.3 Program structure

G_code programs can always be freely programmed. The most important commands that

are included in the rule:

● Set a machining plane

● Call a tool (T and D)

● Call a work offset

● Technology values such as feedrate (F), feedrate type (G94, G95,....), speed and

direction of rotation of the spindle (S and M)

● Positions and calls, technology functions (cycles)

● End of program

For G code programs, before calling cycles, a tool must be selected and the required

technology values F, S programmed.

A blank can be specified for simulation.

See also

Blank input (Page 205)

6.4 Fundamentals

6.4.1 Machining planes

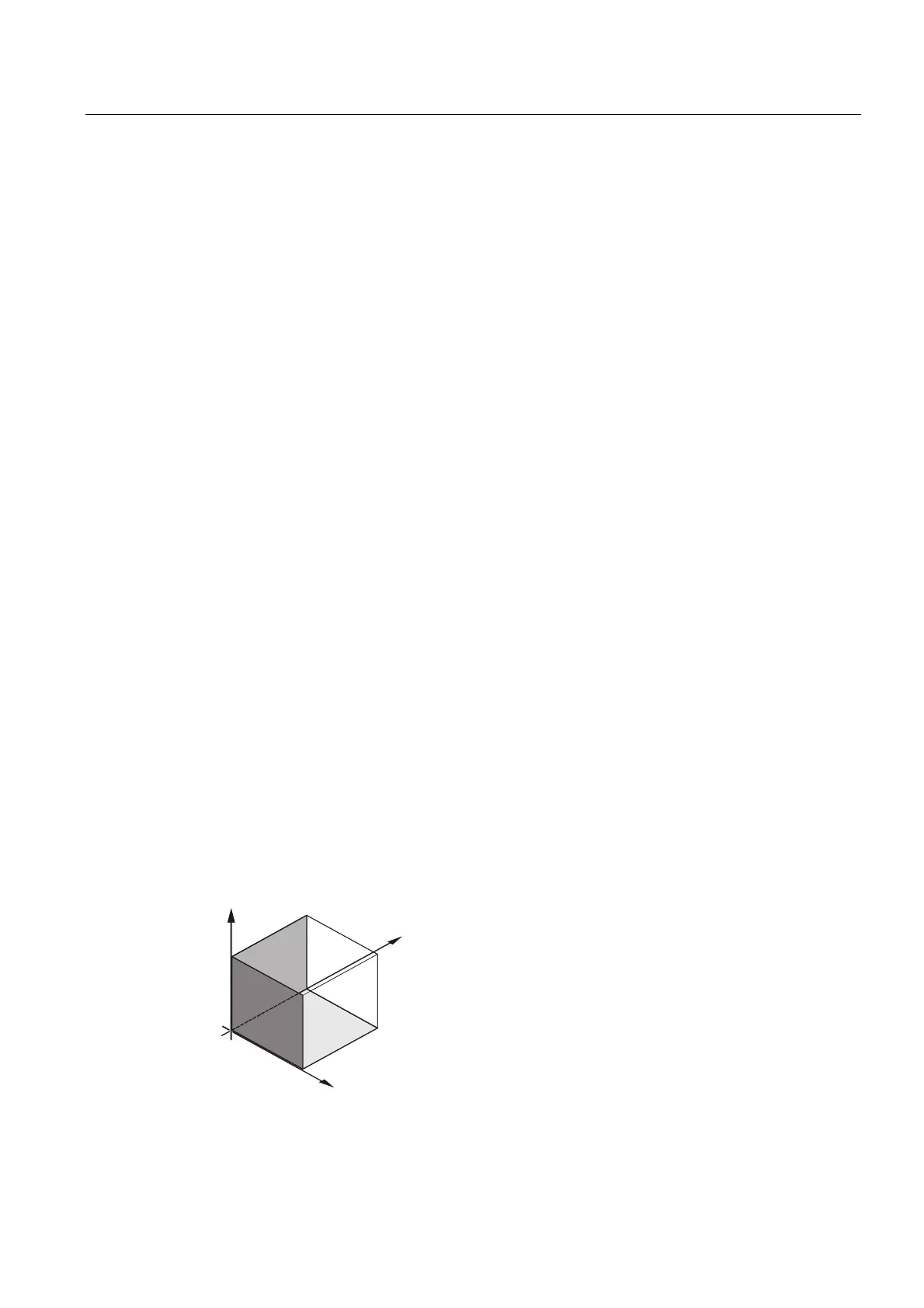

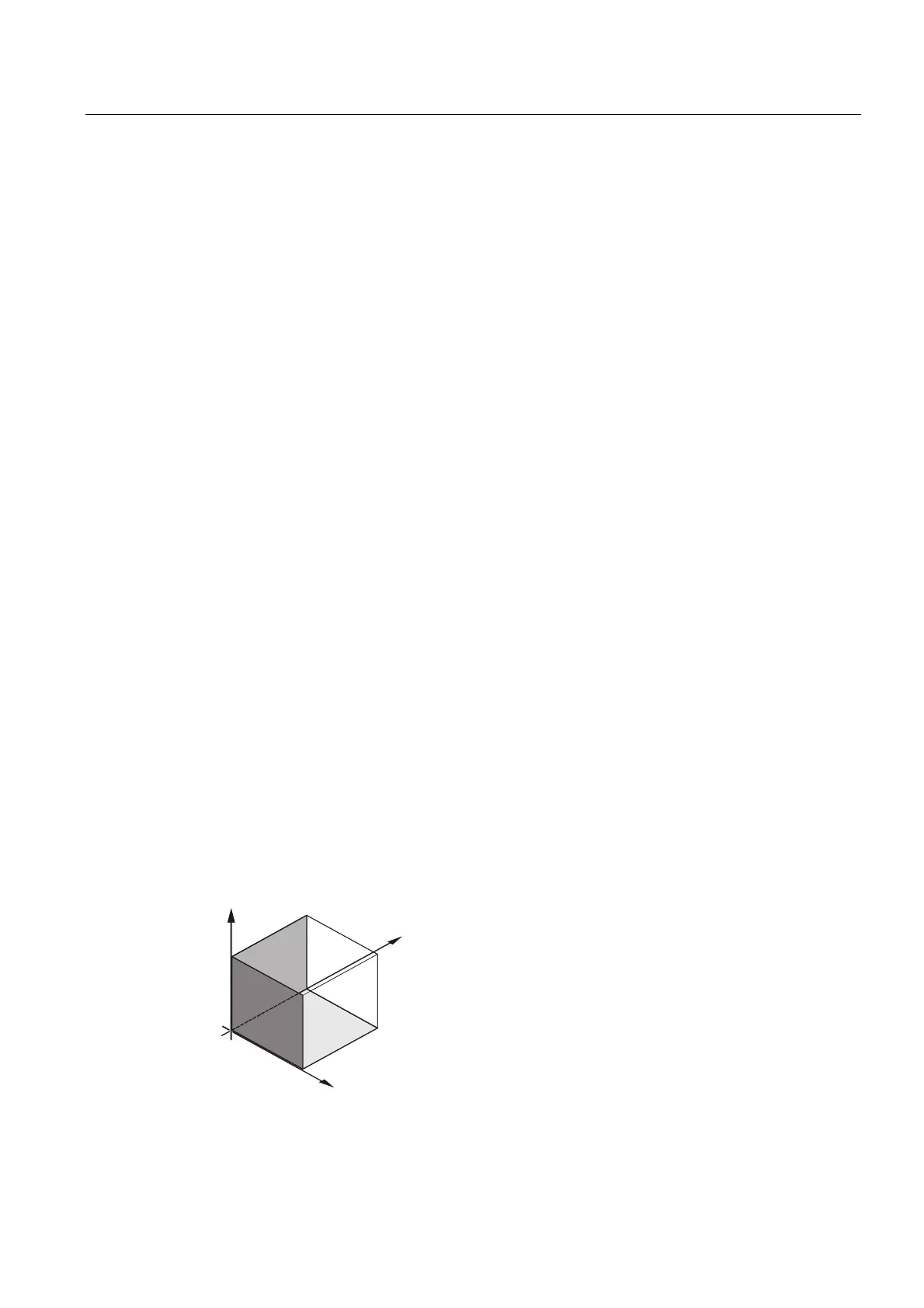

A plane is defined by means of two coordinate axes. The third coordinate axis (tool axis) is

perpendicular to this plane and determines the infeed direction of the tool (e.g. for 2½-D

machining).

When programming, it is necessary to specify the working plane so that the control system

can calculate the tool offset values correctly. The plane is also relevant to certain types of

circular programming and polar coordinates.

;

<

=

<

=

=

;

;

<

*

*

*

Loading...

Loading...