Programming technology functions (cycles)

8.1 Drilling

Turning

284 Operating Manual, 03/2013, 6FC5398-8CP40-3BA1

Procedure

1. The part program or ShopTurn program to be processed has been

created and you are in the editor.

2. Press the "Drilling" softkey.

3. Press the "Drilling Reaming" softkey.

4. Press the "Reaming" softkey.

The "Reaming" input window opens.

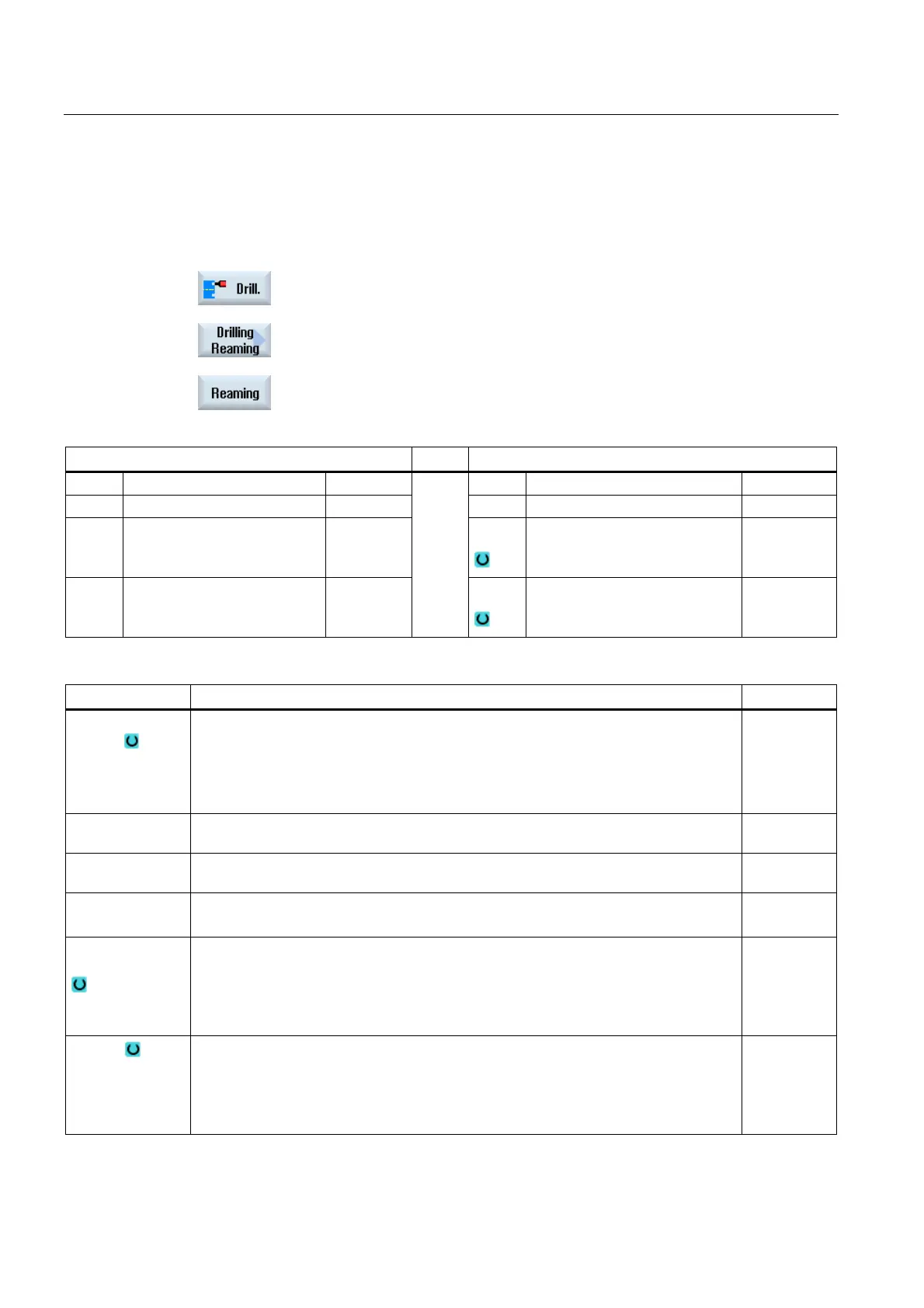

Parameters, G code program Parameters, ShopTurn program

PL Machining plane T Tool name

RP Retraction plane mm D Cutting edge number

SC Safety clearance mm F

Feedrate mm/min

mm/rev

F Feedrate *

S / V

Spindle speed or constant

cutting rate

rpm

m/min

Parameter Description Unit

Machining

position (only

for G code)

• Single position

Drill hole at programmed position

• Position pattern

Position with MCALL

Z0 (only for G

code)

Reference point Z mm

FR (only for G

code)

Feedrate during retraction *

FR (only for

ShopTurn)

Feedrate during retraction mm/min

mm/rev

Machining

surface

(only for

ShopTurn)

• Face C

• Face Y

• Peripheral surface C

• Peripheral surface Y

Position

(only for

ShopTurn)

• At the front (face)

• At the rear (face)

• Outside (peripheral surface)

• Inside (peripheral surface)

Loading...

Loading...