Programming technology functions (cycles)

8.2 Rotate

Turning

Operating Manual, 03/2013, 6FC5398-8CP40-3BA1

329

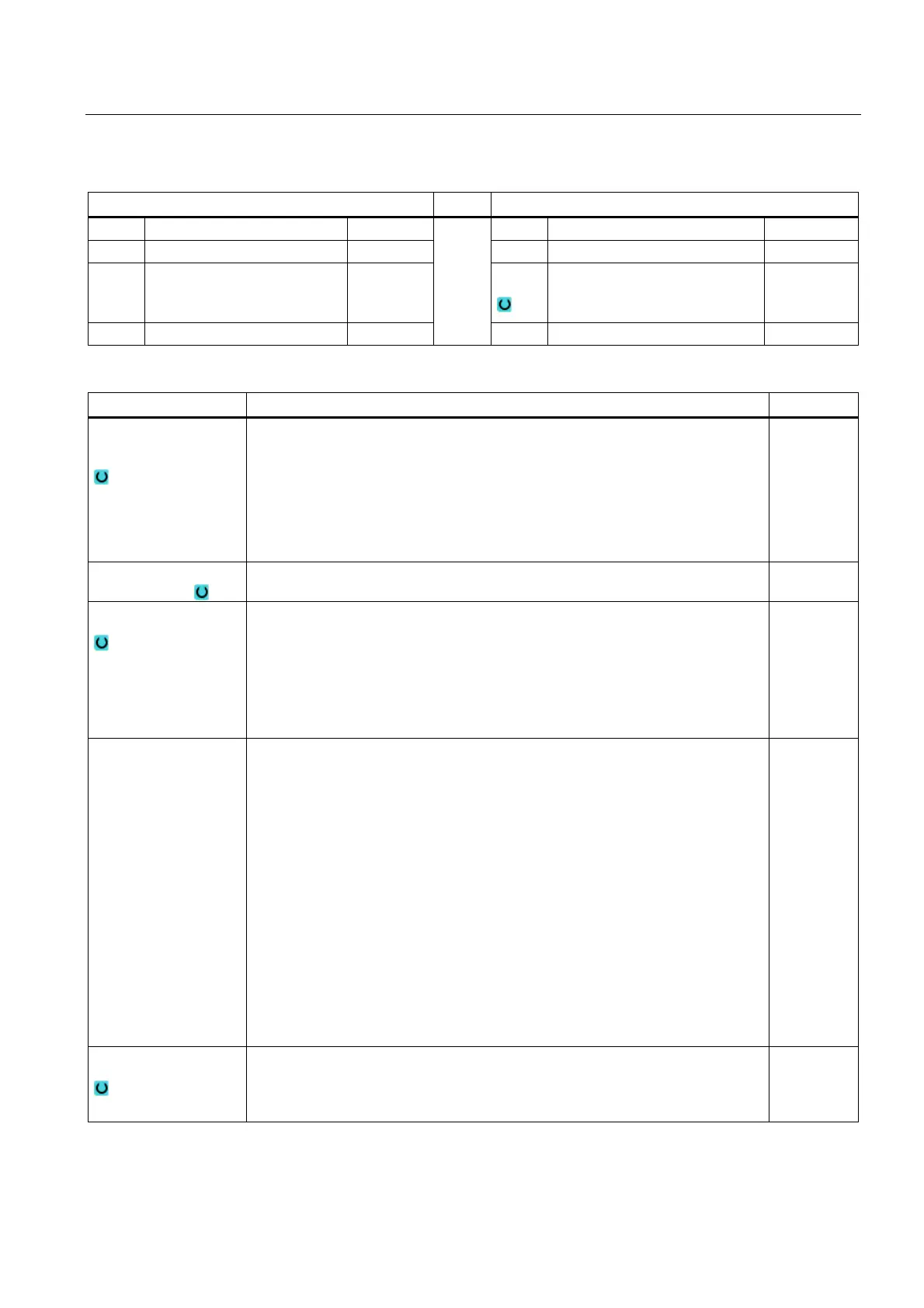

Parameters, G code program Parameters, ShopTurn program

PL Machining plane T Tool name

D Cutting edge number

S / V

Spindle speed or constant

cutting rate

rpm

m/min

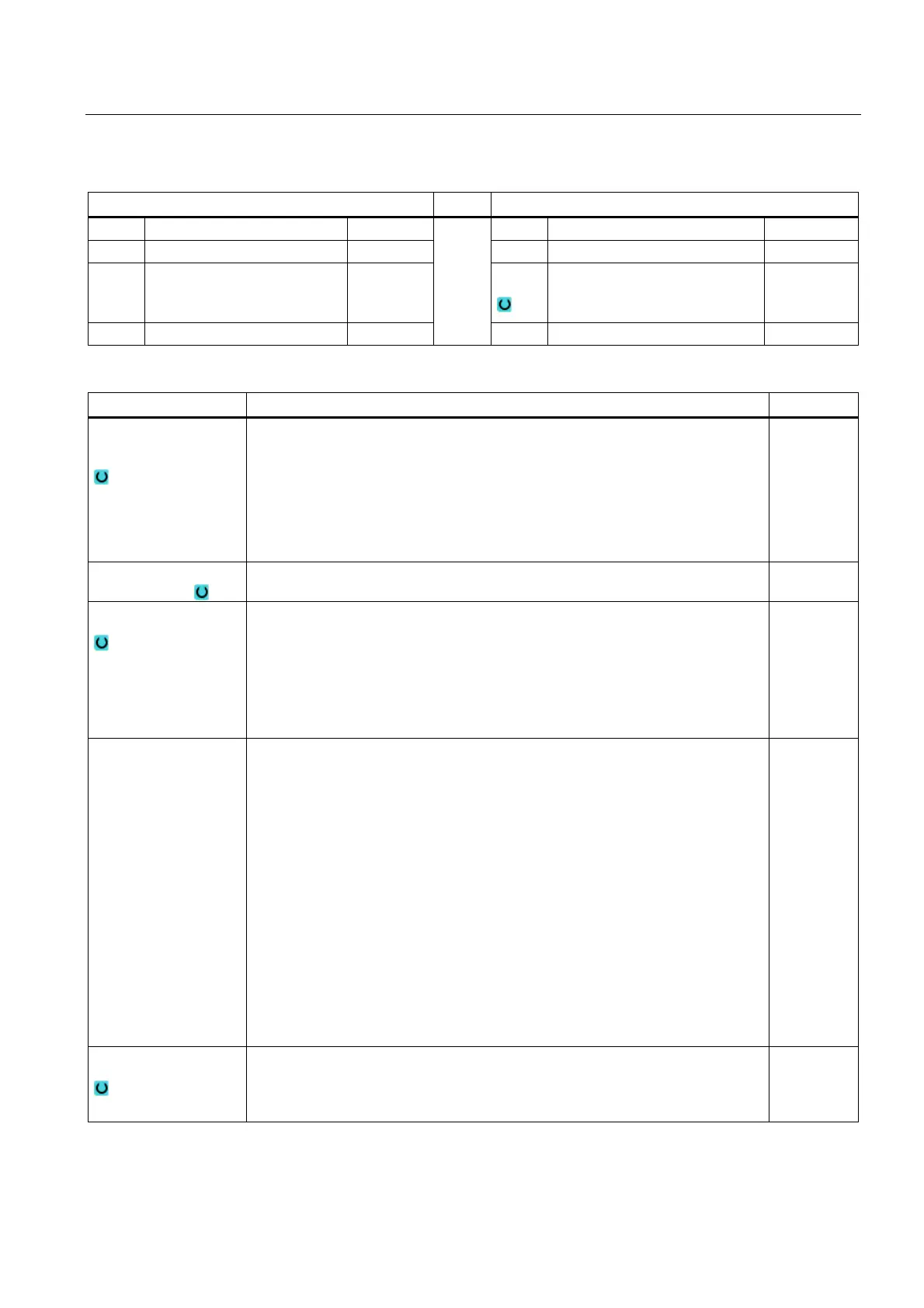

Parameter Description Unit

Table

Thread table selection:

• without

• ISO metric

• Whitworth BSW

• Whitworth BSP

• UNC

Selection - (not for

table "Without")

Data, table value, e.g. M10, M12, M14, ...

P

Select the thread pitch / turns for table "without" or specify the thread pitch/turns

corresponding to the selection in the thread table:

• Thread pitch in mm/revolution

• Thread pitch in inch/revolution

• Thread turns per inch

• Thread pitch in MODULUS

mm/rev

in/rev

turns/"

MODULUS

G Change in thread pitch per revolution - (only for P = mm/rev or in/rev)

G = 0: The thread pitch P does not change.

G > 0: The thread pitch P increases by the value G per revolution.

G < 0: The thread pitch P decreases by the value G per revolution.

If the start and end pitch of the thread are known, the pitch change to be

programmed can be calculated as follows:

|P

e

2

- P

2

|

G = ----------------- [mm/rev

2

]

2 * Z

1

The meanings are as follows:

P

e

: End pitch of thread [mm/rev]

P

a

: Start pitch of thread [mm/rev]

Z

1

: Thread length [mm]

A larger pitch results in a larger distance between the thread turns on the

workpiece.

mm/rev

2

Machining

• ∇ (roughing)

• ∇∇∇ (finishing)

• ∇ + ∇∇∇ (roughing and finishing)

Loading...

Loading...