Programming technology functions (cycles)

8.3 Contour turning

Turning

Operating Manual, 03/2013, 6FC5398-8CP40-3BA1

375

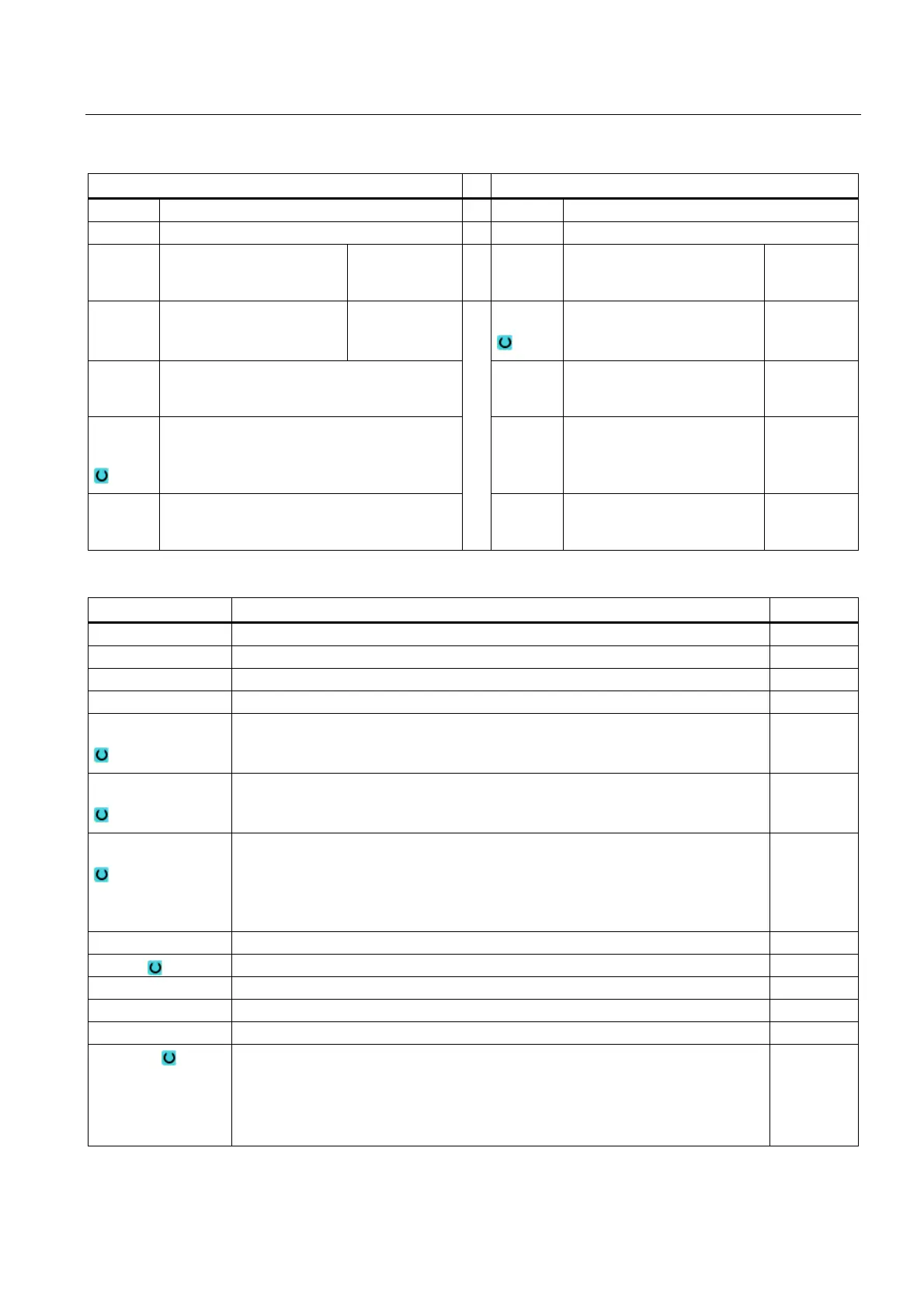

Parameters, G code program Parameters, ShopTurn program

PRG Name of the program to be generated T Tool name

PL Machining plane D Cutting edge number

RP Retraction plane – (only for

longitudinal machining

direction)

mm F Feedrate mm/rev

SC Safety clearance mm S / V

Spindle speed or constant

cutting rate

rpm

m/min

CON Name of the updated blank contour for residual

material machining (without the attached

character "_C" and double-digit number)

Residual

material

With subsequent residual material removal

• Yes

• No

CONR Name to save the updated unmachined-part

contour for residual material removal - (only

"Yes" for residual material removal)

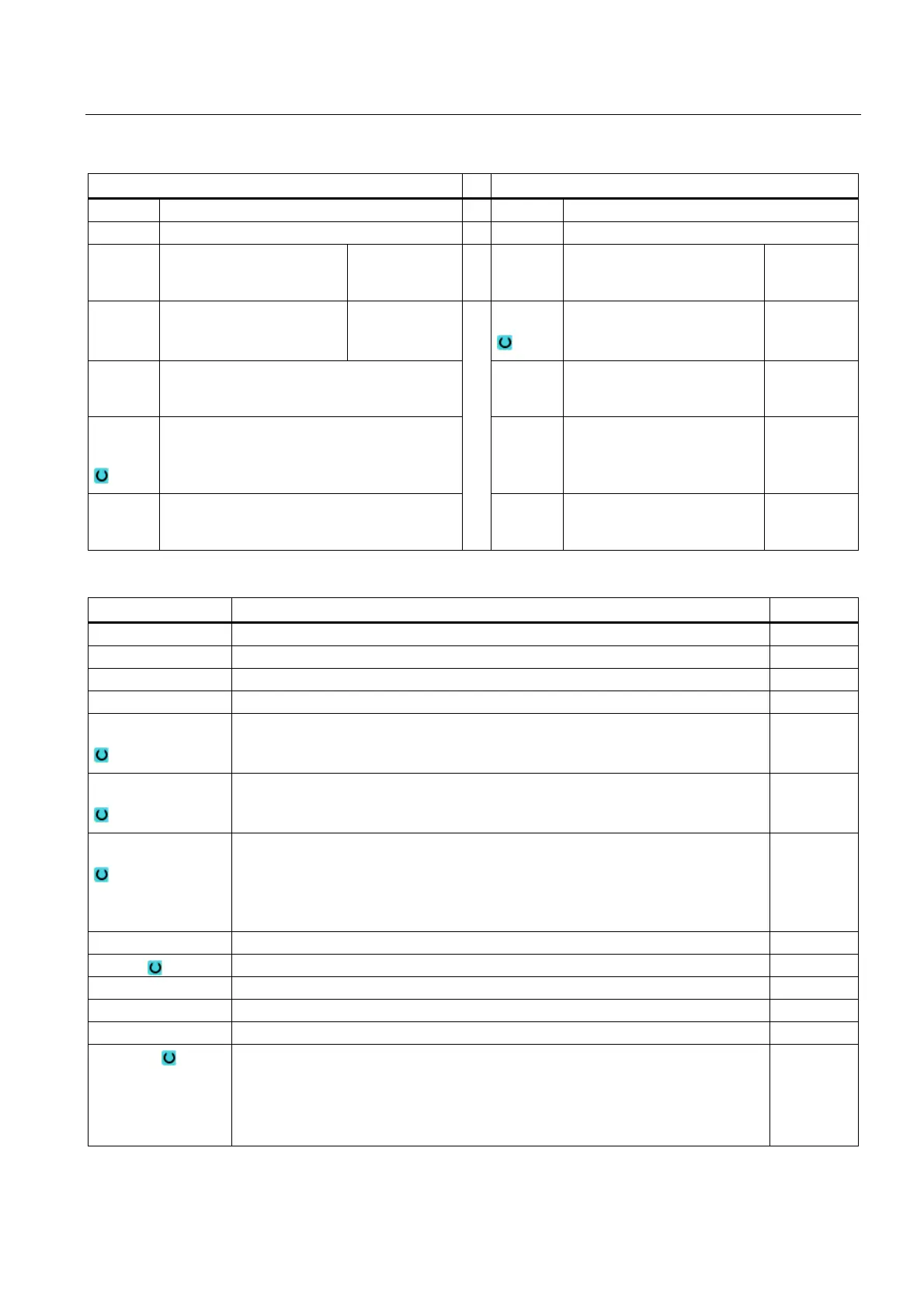

parameters Description Unit

FX (only ShopTurn) Feedrate in X direction mm/rev

FZ (only ShopTurn) Feedrate in Z direction mm/rev

FX (only G Code) Feedrate in X direction *

FZ (only for G code) Feedrate in Z direction *

Machining

• ∇ (roughing)

• ∇∇∇ (finishing)

Machining direction

• Face

• Longitudinal

Position

• front

• back

• internal

• external

D Maximum depth infeed - (only for ∇) mm

UX or U Finishing allowance in X or finishing allowance in X and Z – (only for ∇) mm

UZ Finishing allowance in Z – (only for ∇) mm

XDA 1. Grooving limit tool ∅ (abs) – (end face or rear face only) mm

XDB 2. Grooving limit tool ∅ (abs) – (end face or rear face only) mm

Allowance Allowance for prefinishing

• Yes

U1 contour allowance

• No

Loading...

Loading...