Programming technology functions (cycles)

9.1 Drilling

Turning

316 Operating Manual, 01/2015, 6FC5398-8CP40-5BA2

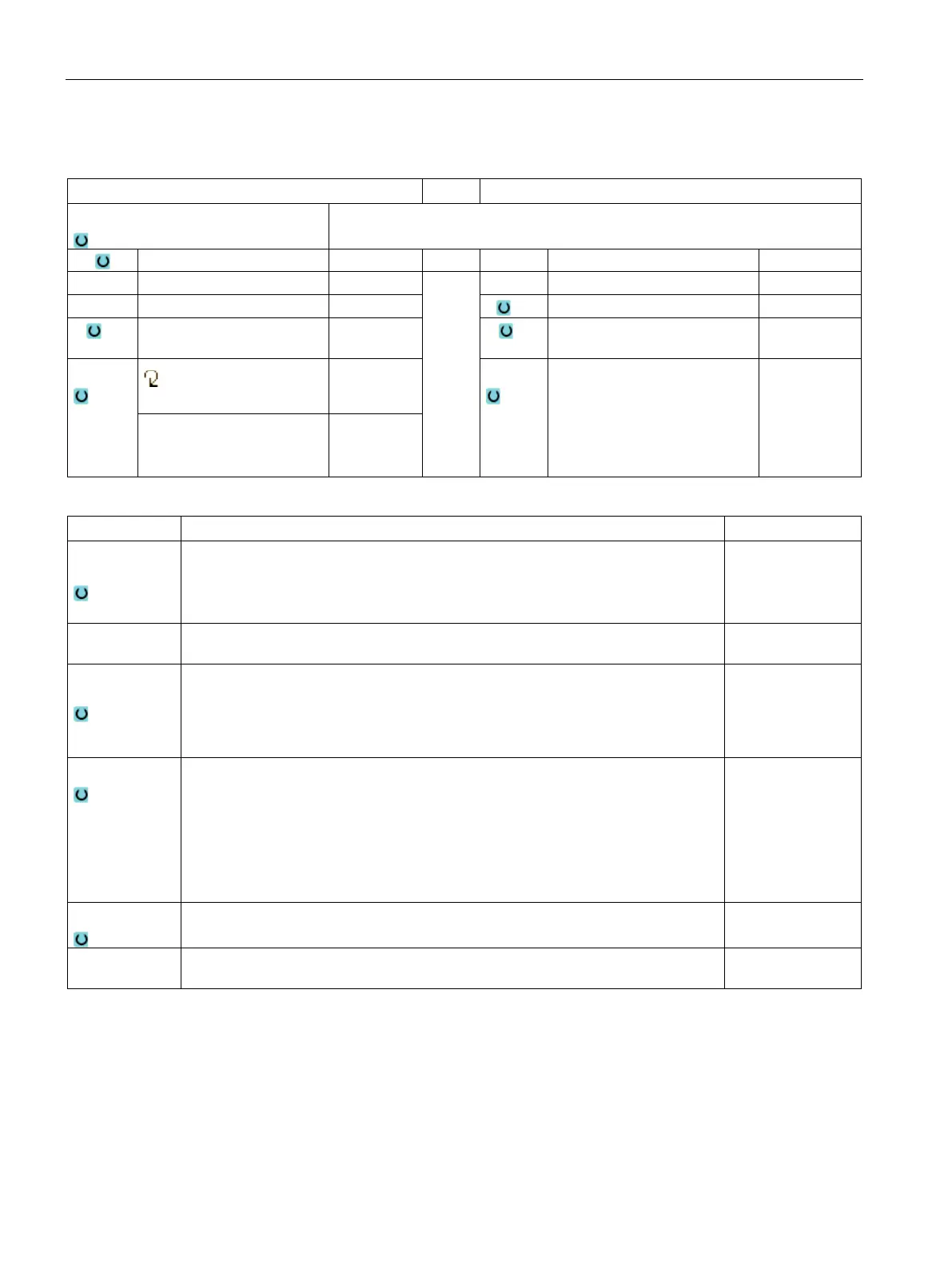

Parameters in the "Input complete" mode

G code program parameters

ShopTurn program parameters

Input

• Complete

PL Machining plane

SC Safety clearance mm D Cutting edge number

F F Feedrate mm/min

S / V

Direction of spindle rotation

S / V

Spindle speed or constant

cutting rate

rpm

m/min

Spindle speed or constant

cutting rate

rpm

Dis-

Machining

position

(only G

code)

• Single position

Drill hole at programmed position

• Position pattern with MCALL

Z0 (only G

Reference point Z mm

Machining

surface

(only Shop-

• Face

• Face B

• Peripheral

Drilling depth

• Shank (drilling depth in relation to the shank)

The drill is inserted into the workpiece until the drill shank reaches the value

programmed for Z1. The angle entered in the tool list is taken into account.

• Tip (drilling depth in relation to the tip)

The drill is inserted into the workpiece until the drill tip reaches the value pro-

Z1

Final drilling depth (abs) or final drilling depth in relation to Z0 (inc).

It is inserted into the workpiece until it reaches Z1.

mm

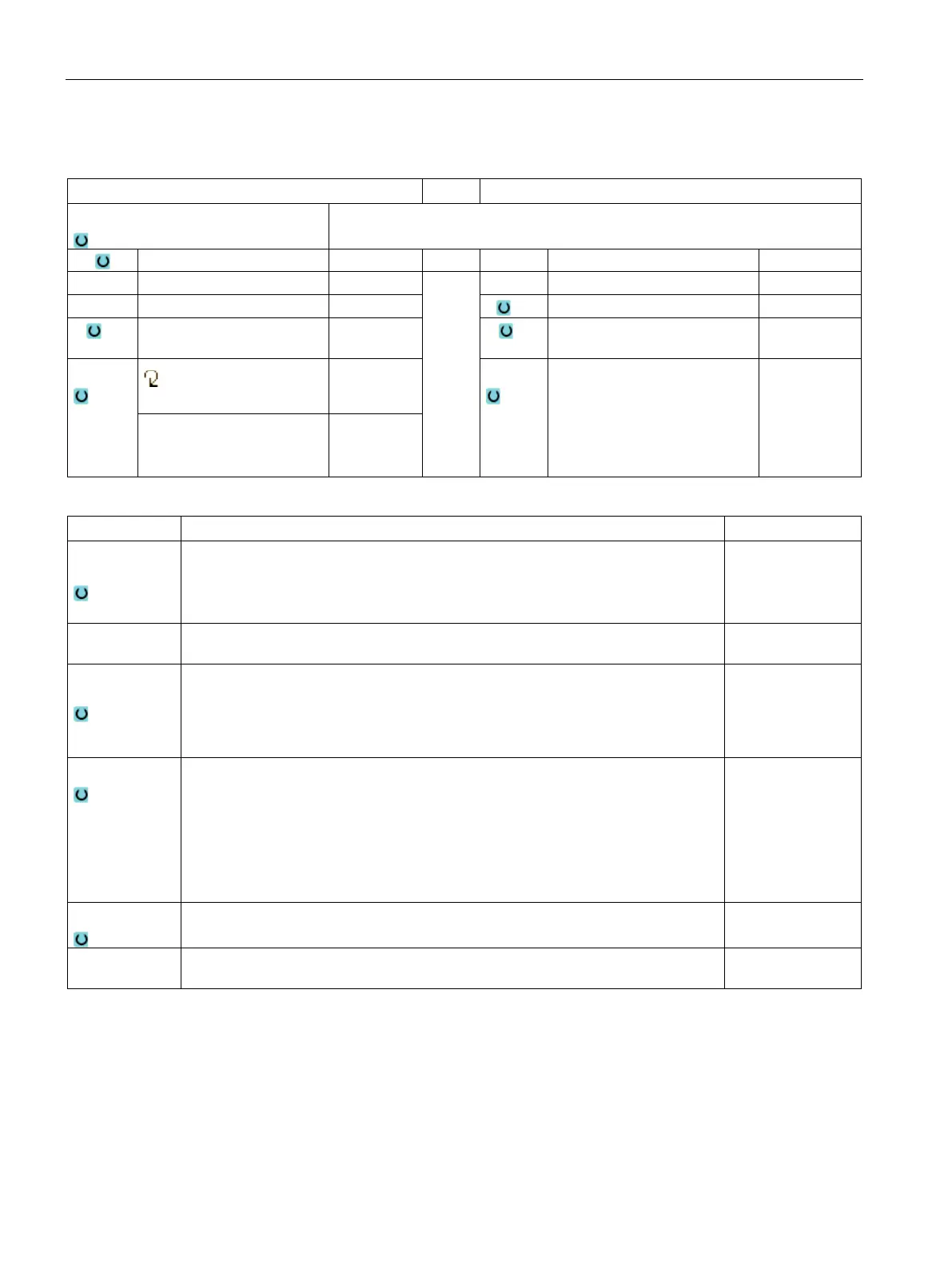

Coolant on -

M function to switch on the coolant.

Loading...

Loading...