Programming technology functions (cycles)

9.5 Contour milling

Turning

550 Operating Manual, 01/2015, 6FC5398-8CP40-5BA2

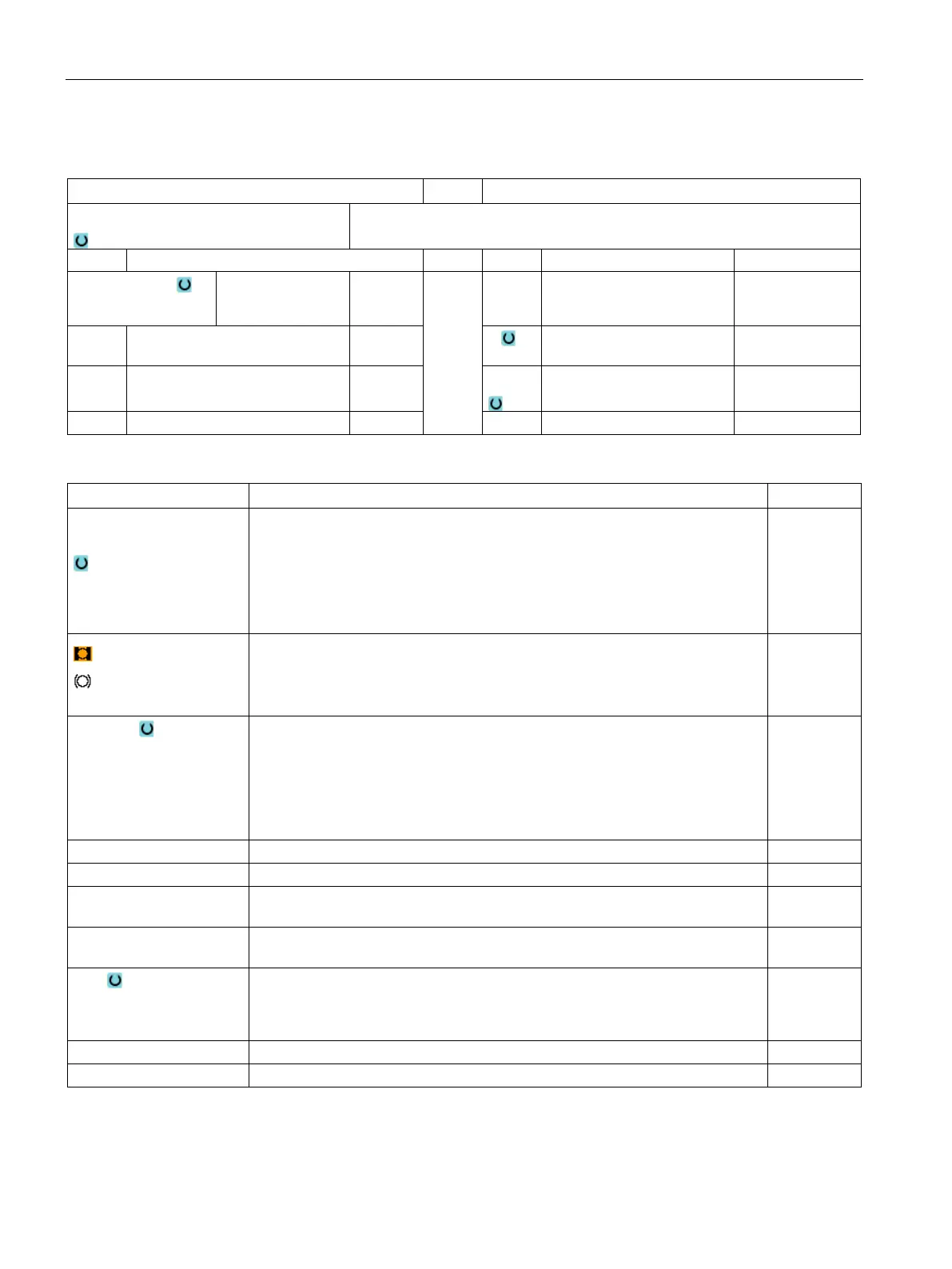

Parameters in the "Input simple" mode

G code program parameters

ShopTurn program parameters

Input

• simple

PRG Name of the program to be generated T Tool name

Milling direction

• Climbing

• Conventional

D Cutting edge number

RP Retraction plane mm F Feedrate mm/min

mm/rev

F Feedrate * S / V

Spindle speed or constant

cutting rate

rpm

m/min

Machining

surface

(only for ShopTurn)

• Face C

• Face Y

• Face B

• Peripheral surface C

• Peripheral surface Y

Clamp/release spindle (only for end face Y/B and peripheral surface Y)

The function must be set up by the machine manufacturer.

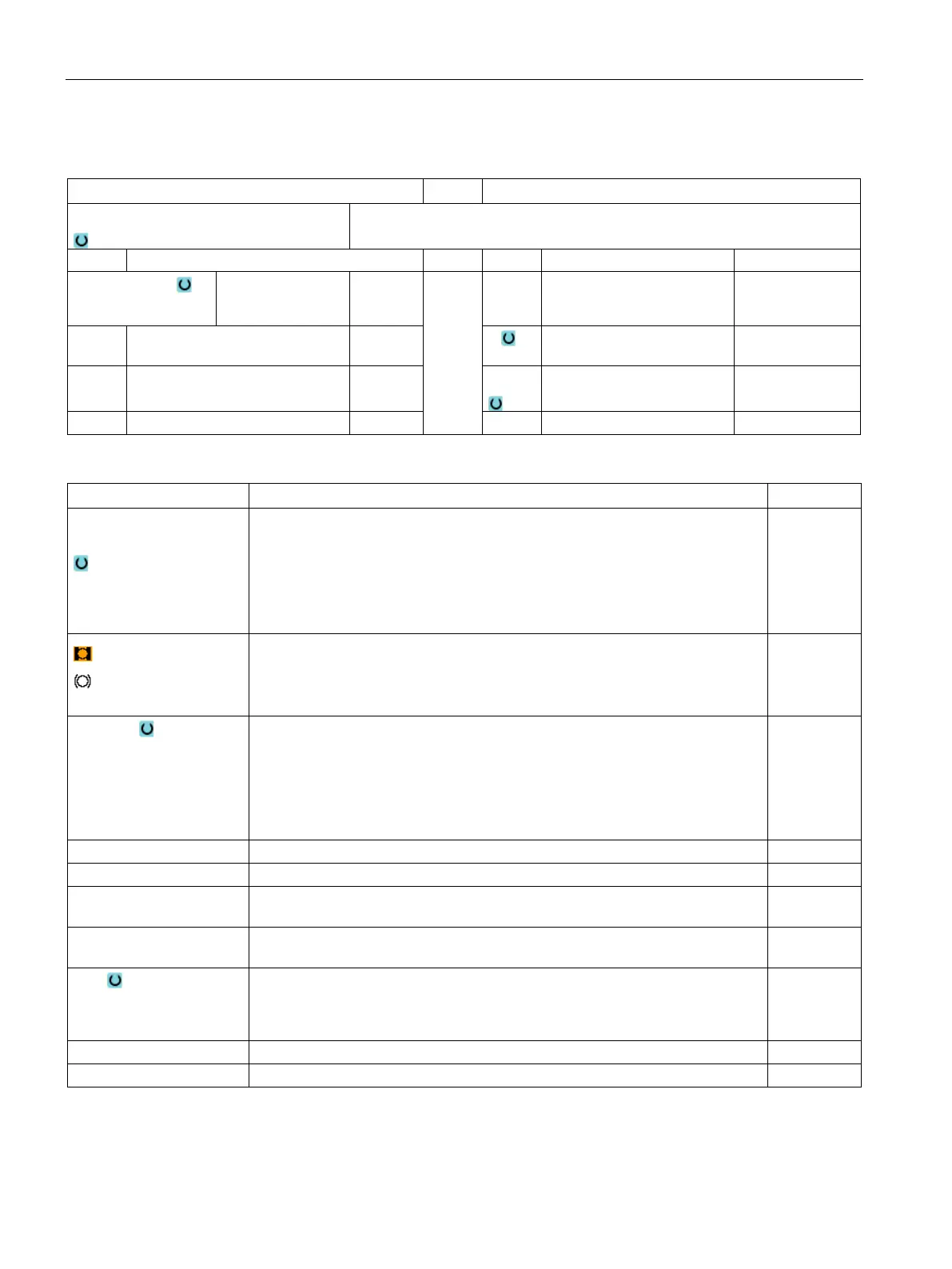

Machining The following machining operations can be selected:

• ∇ (roughing)

• ∇∇∇ base (base finishing)

• ∇∇∇ edge (edge finishing)

• Chamfering

Reference point in the tool axis Z

Pocket depth (abs) or depth referred to Z0 (inc)

CP

Positioning angle for machining area - (only for machining surface, face Y) Degrees

C0

Positioning angle for machining area - (only for machining surface, peripheral

Degrees

DXY

• Maximum plane infeed

• Maximum plane infeed as a percentage of the milling cutter diameter- (only

for ∇ and ∇∇∇ base)

mm

%

Maximum depth infeed - (only for ∇ and ∇∇∇ edge)

Plane finishing allowance – (only for ∇, ∇∇∇ base and ∇∇∇ edge)

Loading...

Loading...