Programming technology functions (cycles)

8.4 Milling

Turning

Operating Manual, 03/2013, 6FC5398-8CP40-3BA1

405

Approach/retraction

1. The tool approaches the center point of the slot at rapid traverse at the height of the

retraction plane and adjusts to the safety distance.

2. The tool is inserted into the material according to the method selected.

3. The longitudinal slot is always machined from inside out using the selected machining

method.

4. The tool moves back to the safety distance at rapid traverse.

Machining type

You can select any of the following machining types for milling the longitudinal slot:

● Roughing

Roughing involves machining the individual planes of the slot one after the other from the

inside out, until depth Z1 or X1 is reached.

● Finishing

During finishing, the edge is always machined first. The slot edge is approached on the

quadrant that joins the corner radius. During the last infeed, the base is finished from the

center out.

● Edge finishing

Edge finishing is performed in the same way as finishing, except that the last infeed

(finish base) is omitted.

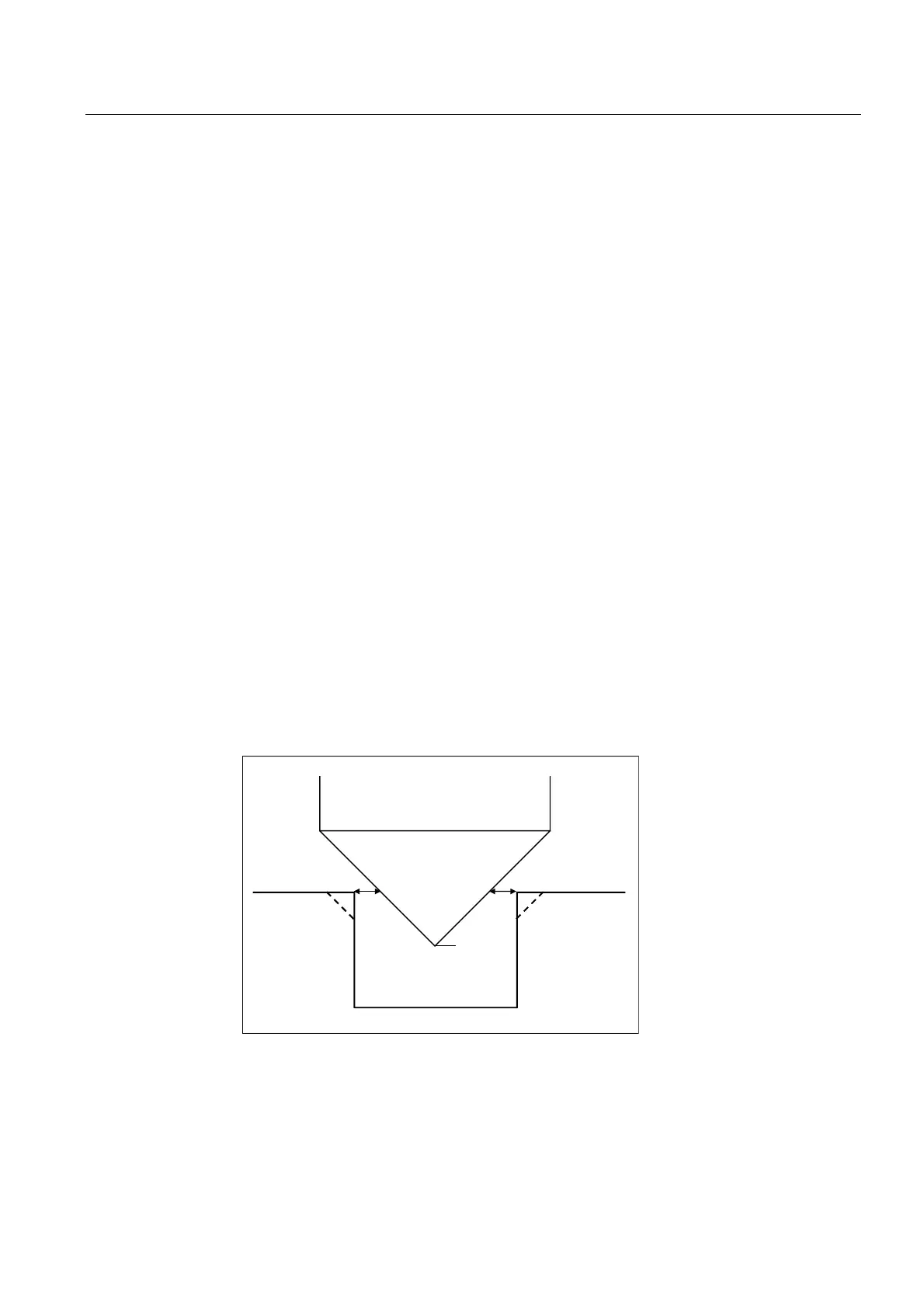

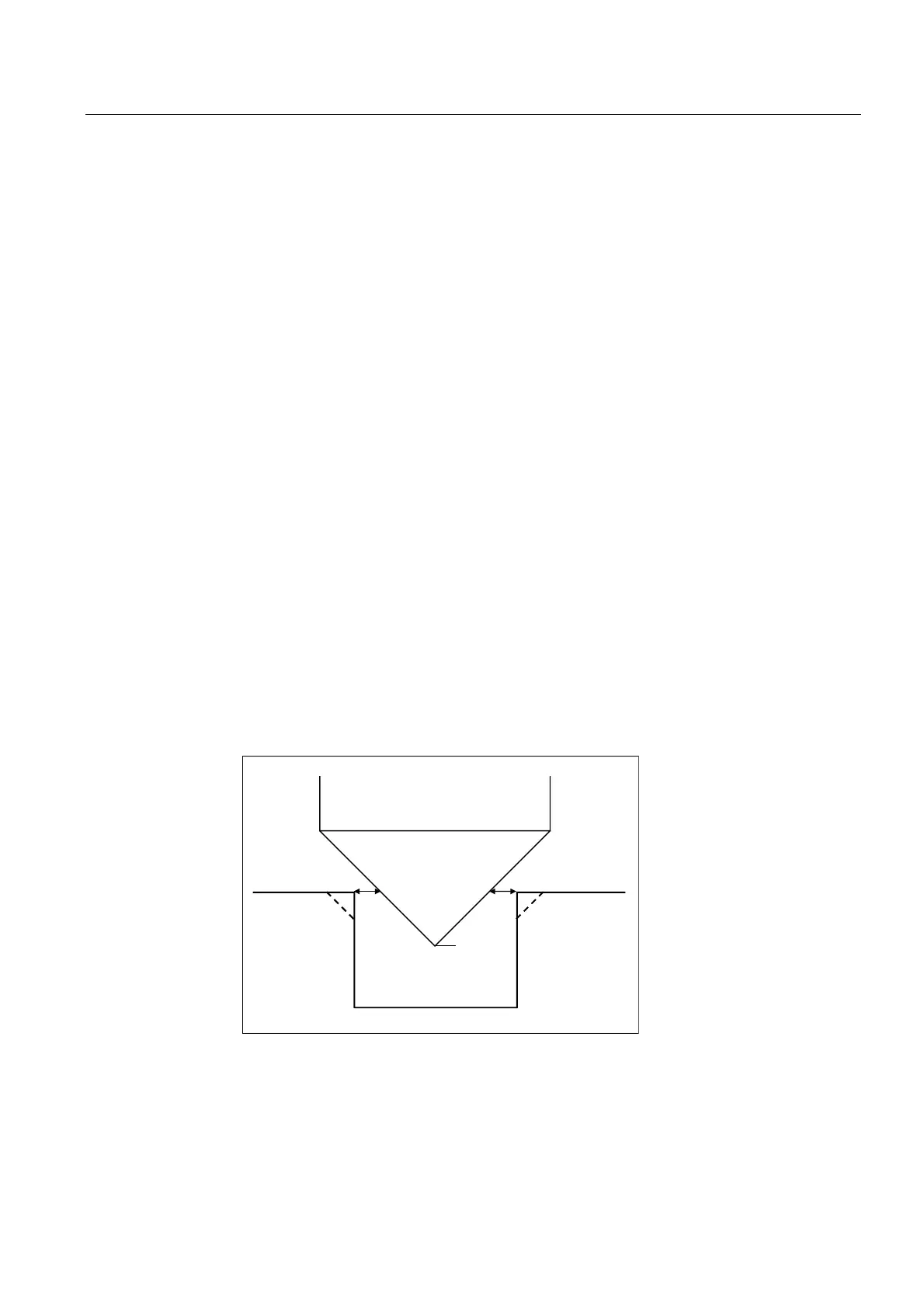

● Chamfering

Chamfering involves edge breaking at the upper edge of the longitudinal slot.

ZFS

SC SC

Figure 8-3 Geometries when chamfering inside contours

Loading...

Loading...