Programming technology functions (cycles)

8.5 Contour milling

Turning

Operating Manual, 03/2013, 6FC5398-8CP40-3BA1

451

Machining type

You can select the machining mode (roughing, finishing, or chamfer) for path milling. If you

want to "rough" and then "finish", you have to call the machining cycle twice (Block 1 =

roughing, Block 2 = finishing). The programmed parameters are retained when the cycle is

called for the second time.

It is also possible to choose between machining the contour with a cutter radius offset or

traversing on the center-point path.

Slot side compensation

When you mill a contour on the peripheral surface (peripheral machining surface C), you can

work with or without a slot wall compensation.

● Slot side compensation off

ShopTurn creates slots with parallel walls when the tool diameter is equal to the slot

width. If the slot width is larger than the tool diameter, the slot walls will not be parallel.

● Slot side compensation on

ShopTurn creates slots with parallel walls also when the slot width is larger than the tool

diameter. If you want to work with a slot wall compensation, you must not program the

contour of the slot, but instead the imagined center path of a bolt inserted in the slot

whereby the bolt touches both walls. Parameter D is used to specify the slot width.

Procedure

1. The part program or ShopTurn program to be processed has been

created and you are in the editor.

2. Press the "Milling" softkey.

3. Press the "Contour milling" and "Path milling" softkeys.

The "Path Milling" input window opens.

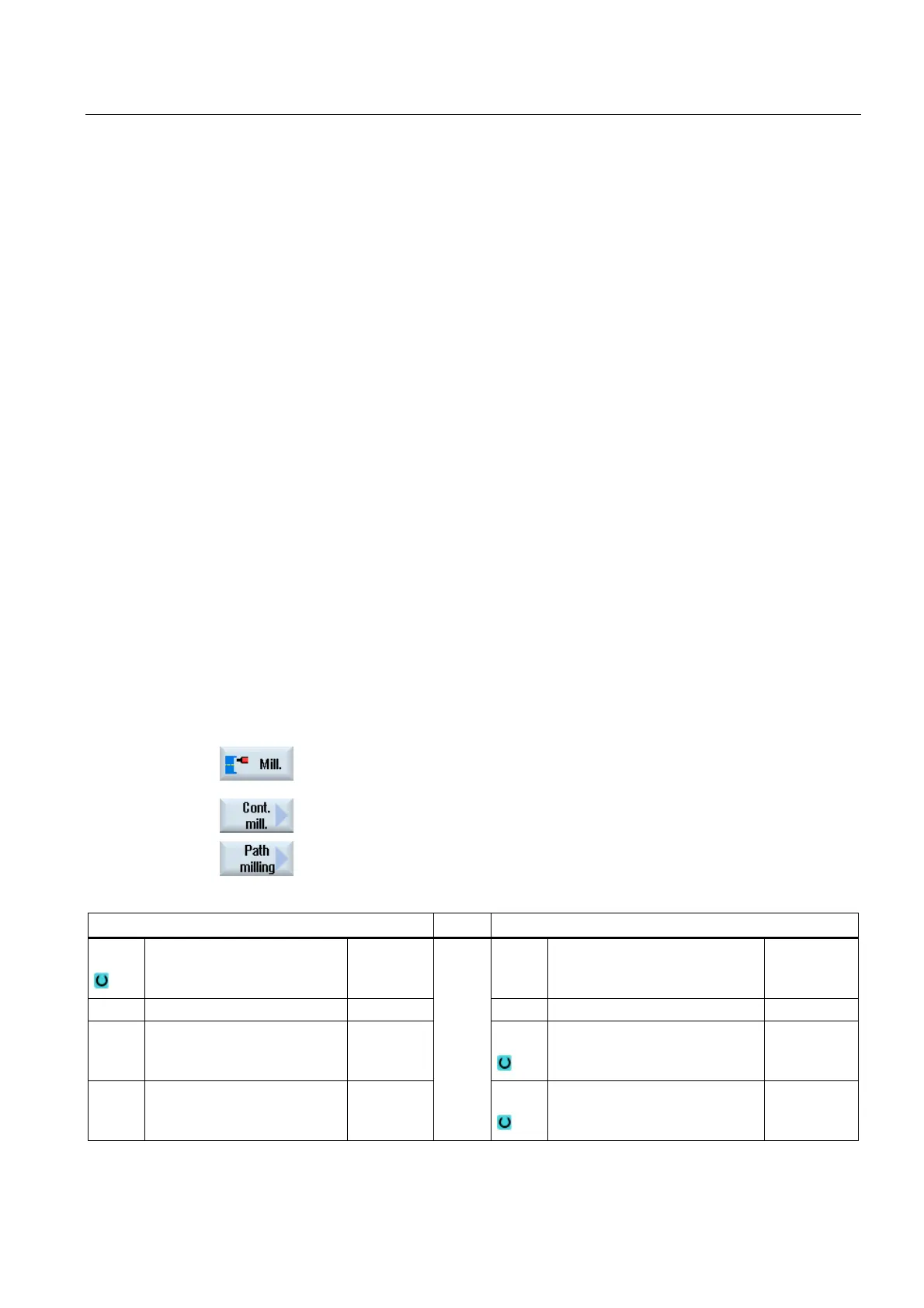

Parameters, G code program Parameters, ShopTurn program

PL

Machining plane T Tool name

RP Retraction plane mm D Cutting edge number

SC Safety clearance mm F

Feedrate mm/min

mm/tooth

F Feedrate *

S / V

Spindle speed or constant

cutting rate

rpm

m/min

Loading...

Loading...