Programming technology functions (cycles)

8.5 Contour milling

Turning

466 Operating Manual, 03/2013, 6FC5398-8CP40-3BA1

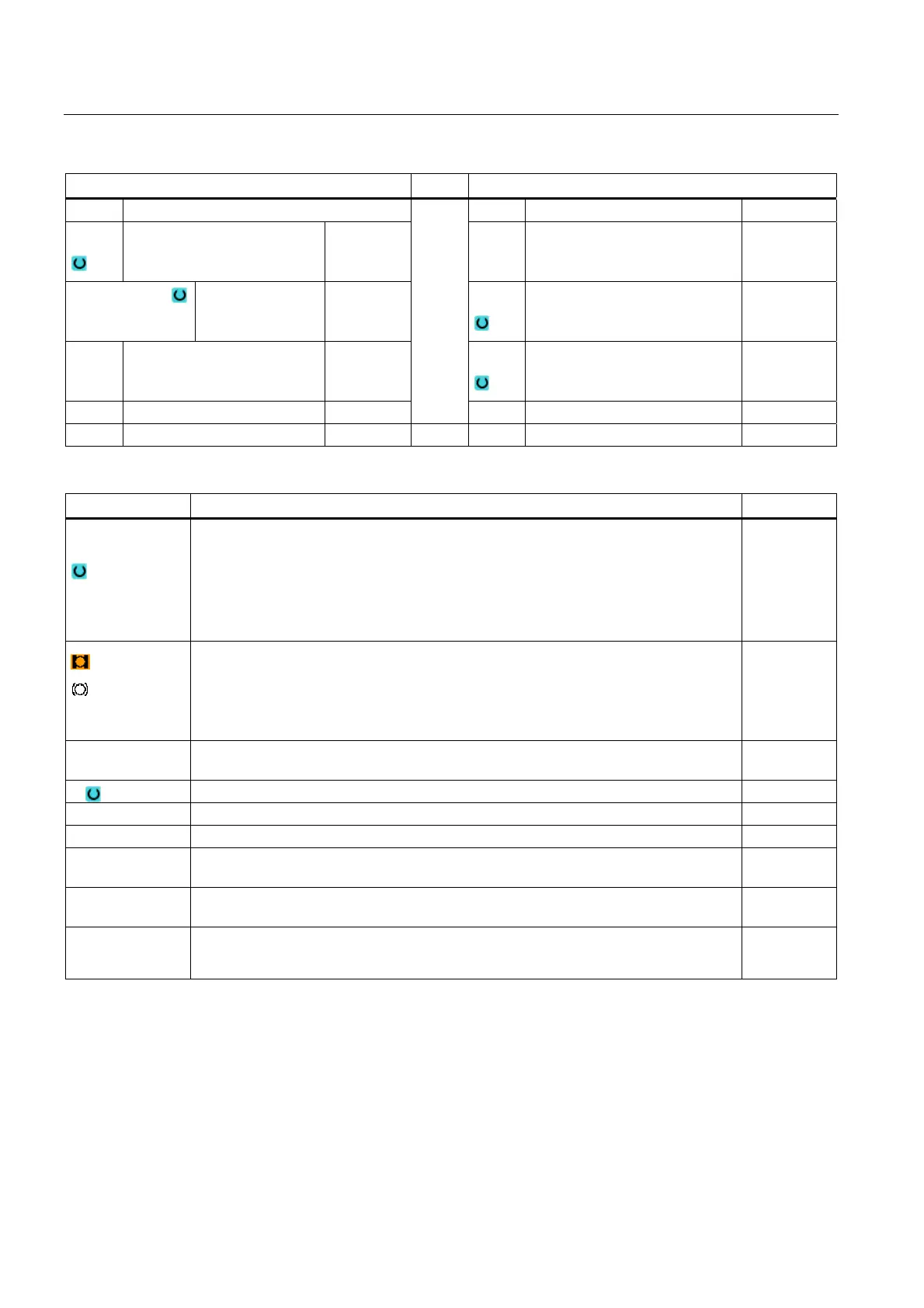

Parameters, G code program Parameters, ShopTurn program

PRG Name of the program to be generated T Tool name

PL

Machining plane D Cutting edge number

Milling direction

• Climbing

• Conventional

F

Feedrate mm/min

mm/tooth

RP Retraction plane mm S / V

Spindle speed or constant

cutting rate

rpm

m/min

SC Safety clearance mm

F Feedrate mm/min

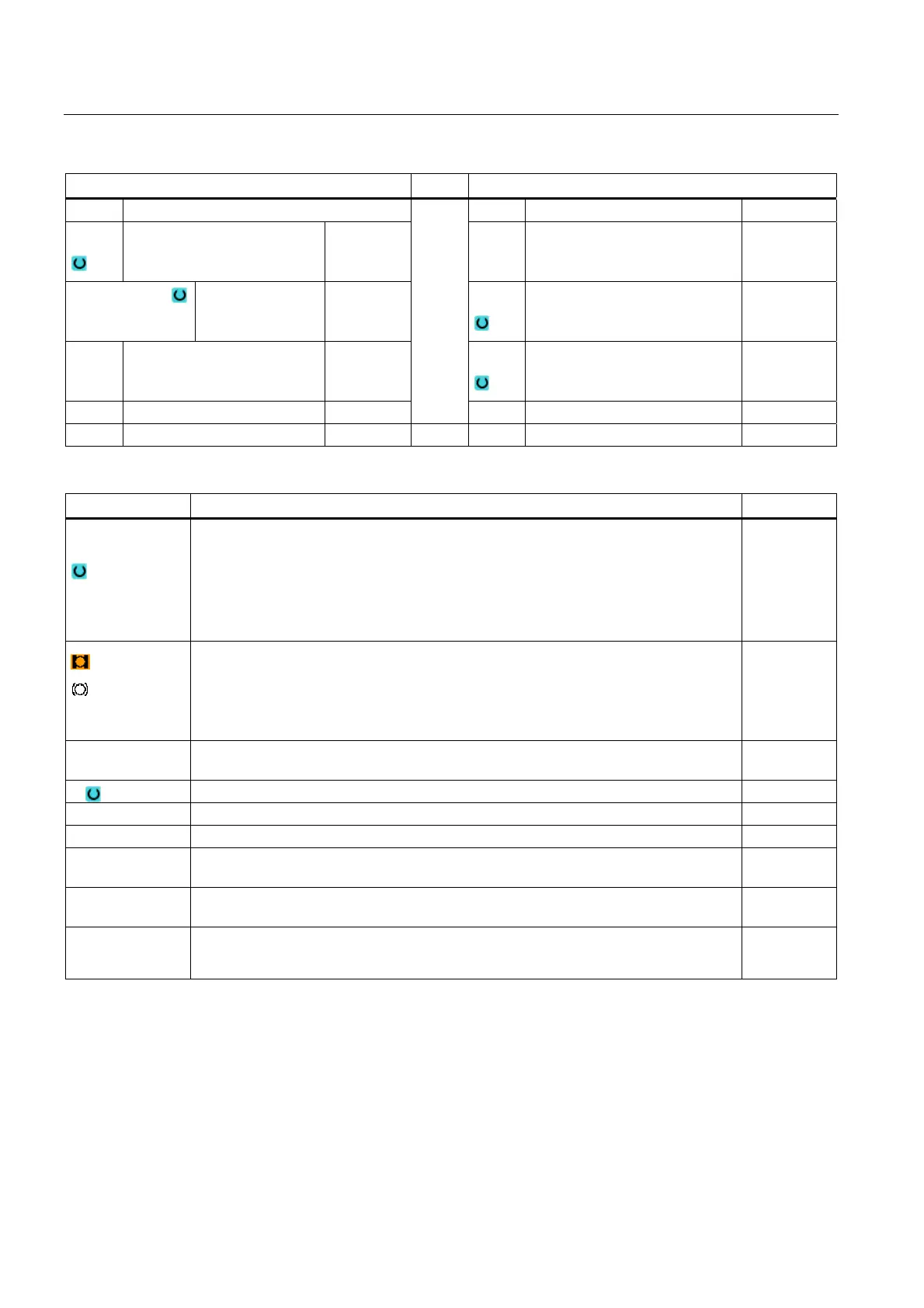

parameters Description Unit

Machining

surface

(only for

ShopTurn)

• Face C

• Face Y

• Face B

• Peripheral surface C

• Peripheral surface Y

(only for

ShopTurn)

Clamp/release spindle (only for end face Y/B and peripheral surface Y)

The function must be set up by the machine manufacturer.

TR Reference tool Tool, which is used in the "stock removal" machining step. This is used

to determine the residual corners.

D Cutting edge number

Z0 Reference point in the tool axis Z mm

Z1 Pocket depth (abs) or depth referred to Z0 or X0 (inc) mm

CP Positioning angle for machining area

- (only for ShopTurn, machining surface, face Y)

Degrees

C0 Positioning angle for machining surface

- (only for ShopTurn, machining surface, peripheral surface Y)

Degrees

DXY

• Maximum plane infeed

• Maximum plane infeed as a percentage of the milling cutter diameter

mm

%

Loading...

Loading...