Multi-channel machining (only 840D sl)

9.2 Multi-channel support (only 840D sl)

Turning

538 Operating Manual, 03/2013, 6FC5398-8CP40-3BA1

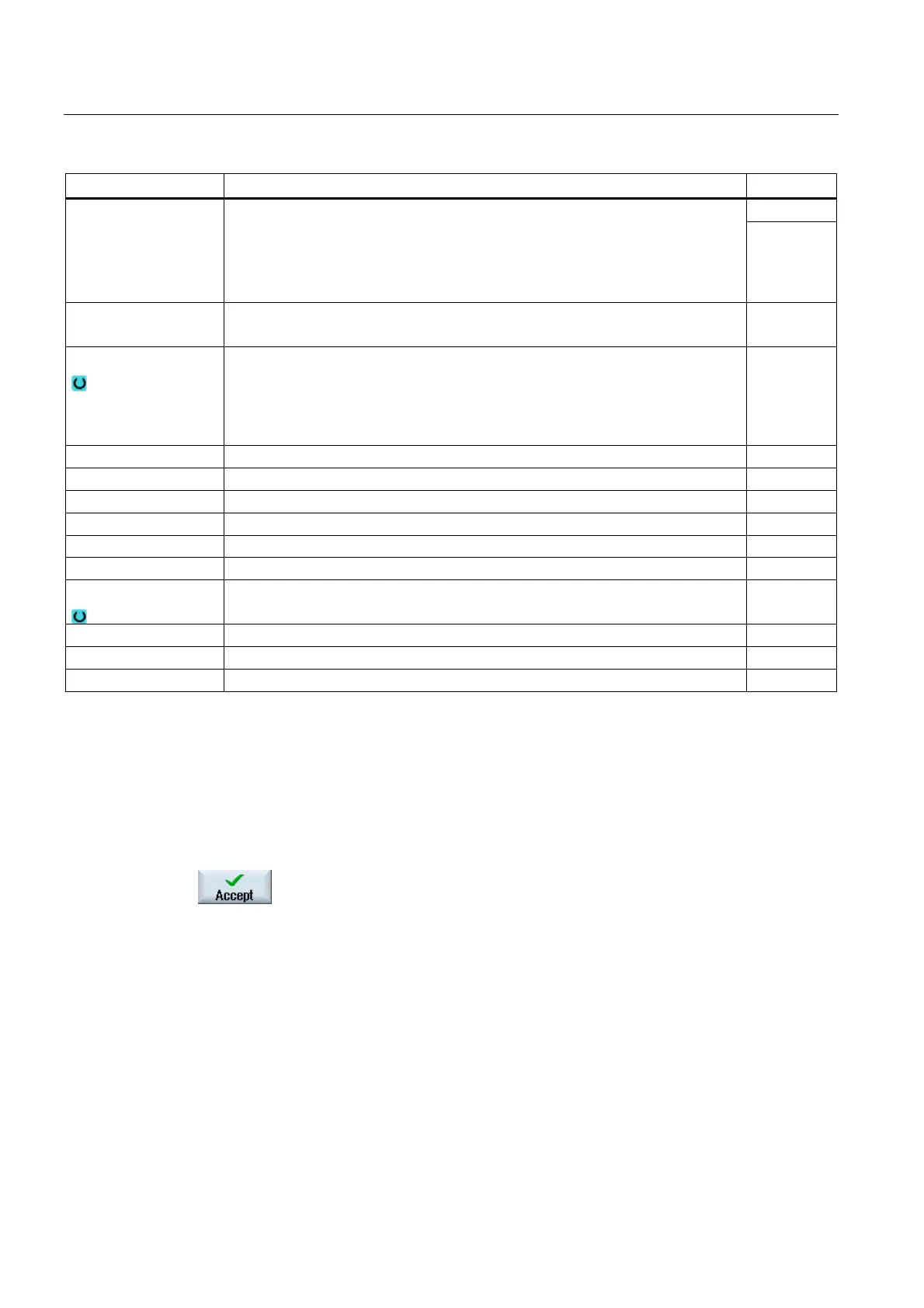

Parameter Description Unit

Write to the

work offset

• Yes

Parameter ZV is displayed

• No

Parameter ZV is not displayed

ZV Z value of the work offset

For G54, the Z value is entered into the work offset.

Blank

• Tube

• Cylinder

• Polygon

• Centered cuboid

ZA Initial dimension mm

ZI Final dimension (abs) or final dimension in relation to ZA (inc) mm

ZB Machining dimension (abs) or machining dimension in relation to ZA (inc) mm

XA Outside diameter – (only for tube and cylinder) mm

XI Inside diameter (abs) or wall thickness (inc) – (only for tube) mm

N Number of edges – (only for polygon)

SW or L

Width across flats or edge length – (only for polygon) mm

W Width of the blank - (only for centered cuboid) mm

L Length of the blank - (only for centered cuboid) mm

S Speed limitation of the counterspindle rev/min

Procedure

1. You have created programs for the multi-channel machining in

the job list and the parameter screen "multi-channel data" is open

in the editor.

2. Enter the data for the cross-channel data.

3. Press the "Accept" softkey.

The multi-channel editor is opened and displays the programs

that have been created.

The cursor is positioned on an empty line before the cycle for the

job list (CYCLE208). This means that you have the option to

enter initializations for the G code program that are immediately

required.

Loading...

Loading...