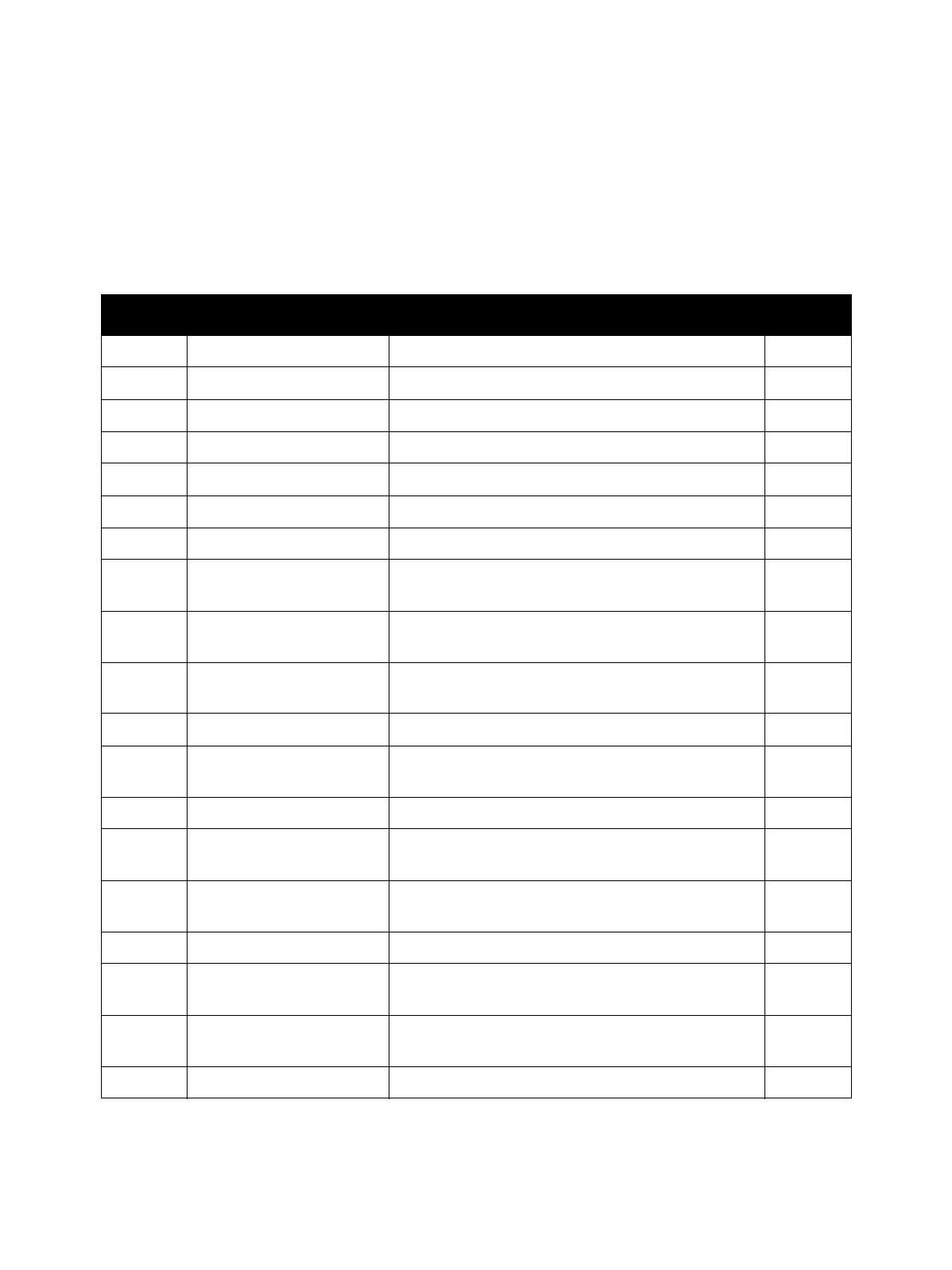

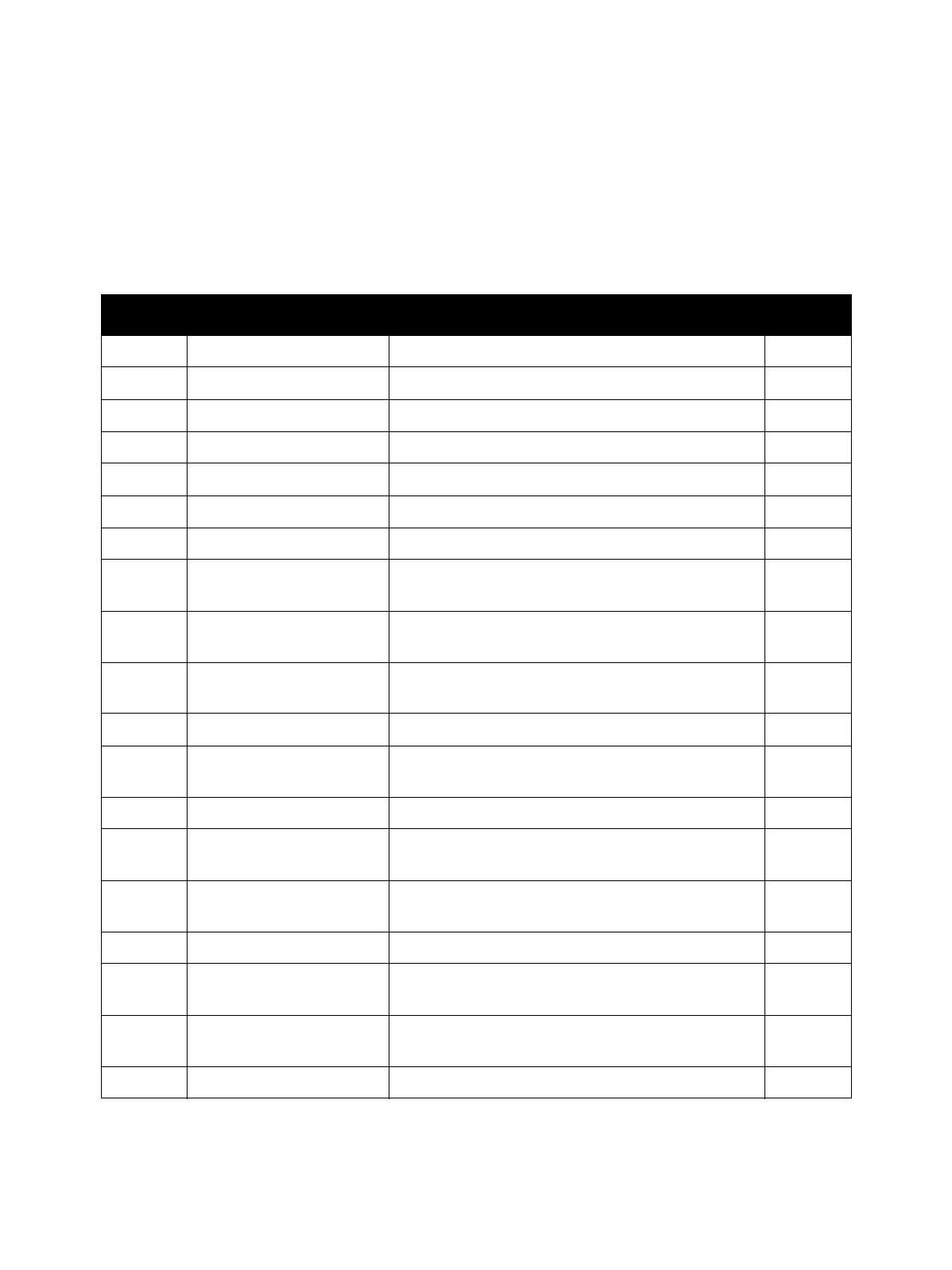

Image Quality

Phaser 3610, WorkCentre 3615 Service Manual 3-7

Image Quality Troubleshooting

Image Quality Defects

The following table lists the print-quality defect corrective procedure, their definition, and the page

where each procedure is provided.

IQ # Defect Description Page

1 Light Print Image density is too light for the entire image area. 3-8

2 Unfused Image Toner has not been fused properly to the paper. 3-11

3 Random Spots Spots are randomly scattered throughout the page. 3-12

4 Blank Prints The entire image area is blank. 3-14

5 Streaks Random streaks appear on the page. 3-17

6 Black Prints All or part of the image is black. 3-19

7 Pitched Black Dots Evenly spaced black dots appear vertically in a line. 3-21

8 Vertical Bands, Voids, or

Streaks

Faded or completely non printed lines that appear in

the process direction.

3-23

9 Ghosting There is a faint ghost image appearing on the page

from the current or previous image.

3-25

10 Light Induced Fatigue Drum Cartridge has been exposed to too much light

and causing density variation.

3-27

11 Background The overall image or text on the page is blurred. 3-28

12 Bead Carry-out Spot deletions that has a center weighted bead of

toner in it.

3-30

13 Jagged Characters Text appears blurry due to jagged edges 3-31

14 Banding A horizontal smear that appears slightly darker than

the original.

3-33

15 Auger marks Uneven density appears in a slanted stripped pattern

at approx. a 20 mm pitch

3-35

16 Wrinkles / Stained Paper The overall output page is wrinkled or stained. 3-37

17 Damage to the Lead Edge

of the Paper

Just the Lead edge of the output is wrinkled, folded or

worn-out.

3-39

18 Incorrect Margins The image area is parallel to the edges of the paper

but has shifted position

3-41

19 Skewed Image The image is not parallel to both sides of the paper. 3-43

Loading...

Loading...