A

B

C

D

E

F

G

H

L

M

N

P

section

N 9.2

2031098/1098S - M.Y. 2007 - edition 00

Engine

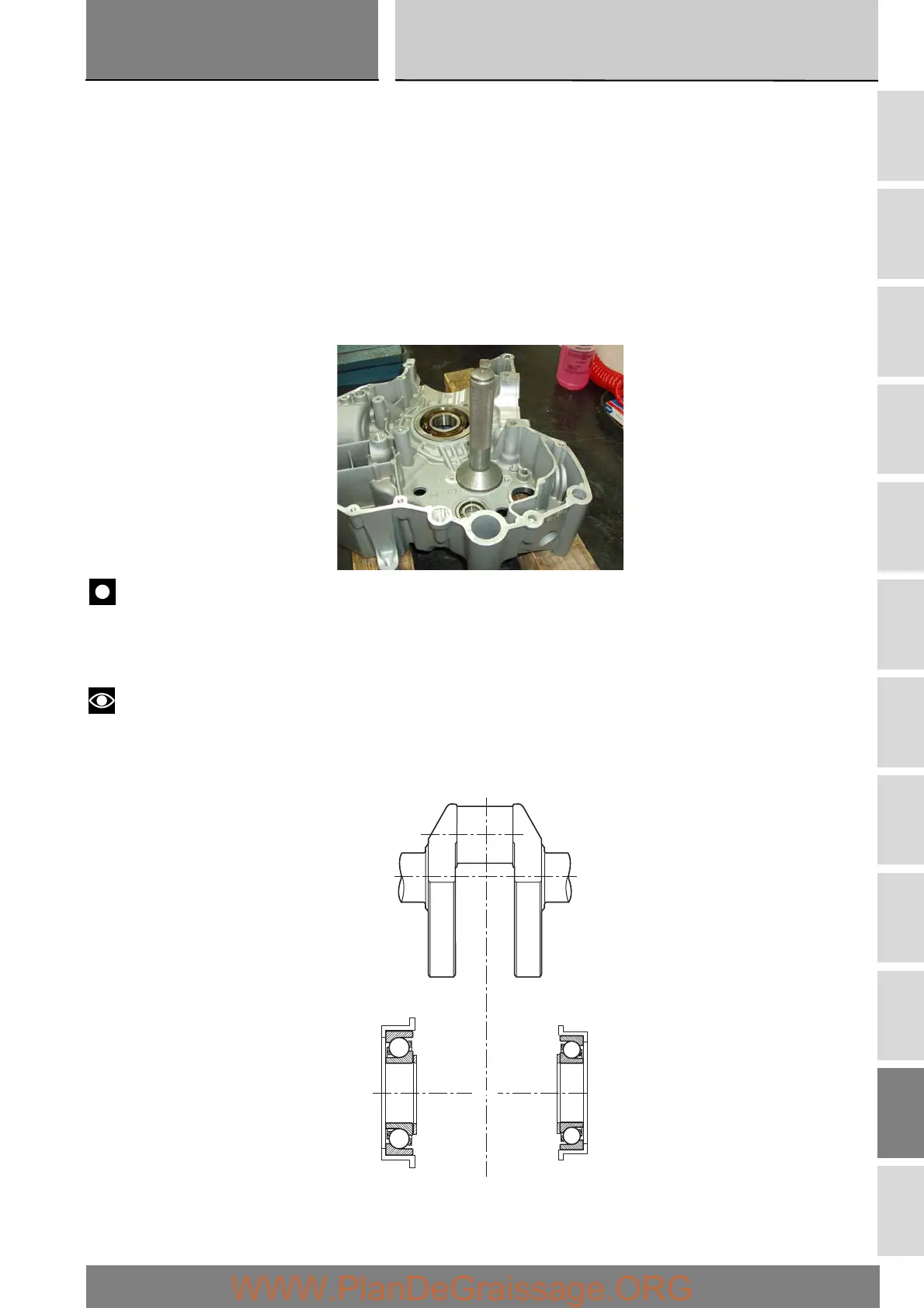

Main bearings

The main bearings have are of the angular contact type with offset inner races so that the balls transmit loads from one groove

to the other along straight lines at an angle to the axis of the bearing. Angular contact thrust bearings are designed to withstand

combined loads (radial and axial loads).

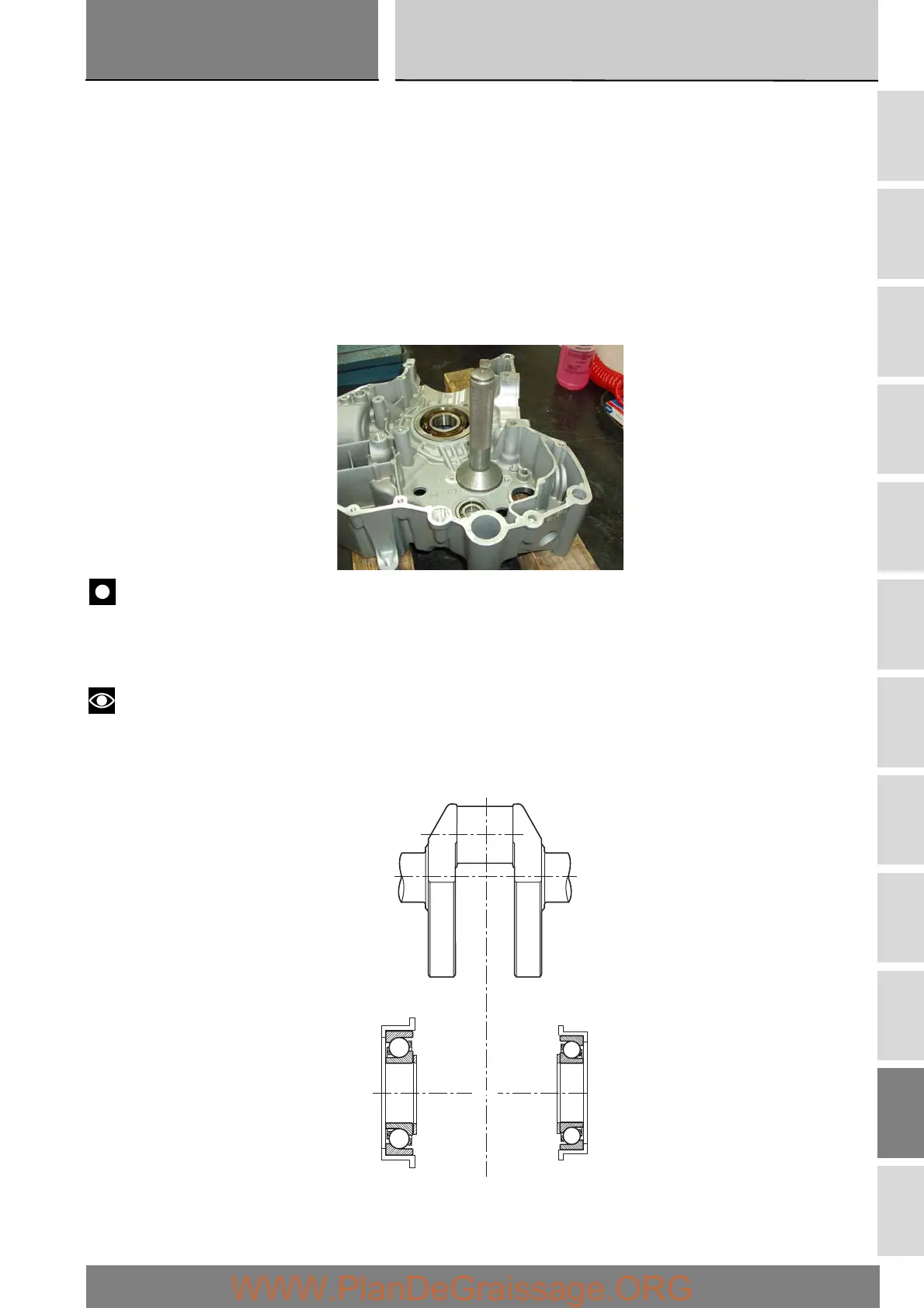

Bearings of this type can bear thrust loads in one direction only. In fact, under the action of a radial load inside the bearing, an

axial force is created that must be counterbalanced by an axial force acting in the opposite direction; that is why these bearings

are generally fitted back to back in pairs.

To renew the bearings proceed as follows:

- heat the crankcase half in an oven up to 100 °C;

- remove the bearing using a drift and hammer;

- install the new bearing (while the crankcase is still hot) keeping it perfectly square in its seat using a tubular drift that only bears

on the outer ring of the bearing;

- allow the parts to cool and check that the bearing is securely seated in the crankcase.

Important

On worn engines, the bearing holder may no longer be a tight fit in the crankcase half.

After having removed the bearing holder, check that the interference fit between the crankcase and the holder with the bearing

installed is no less than 0.03 mm, otherwise the crankcase halves must be renewed.

Notes

For shimming the main bearings, see the chapter at the end of this section.

Crankcase half contact face

Loading...

Loading...