DMTA-10040-01EN, Rev. E, February 2018

Using the Instrument 135

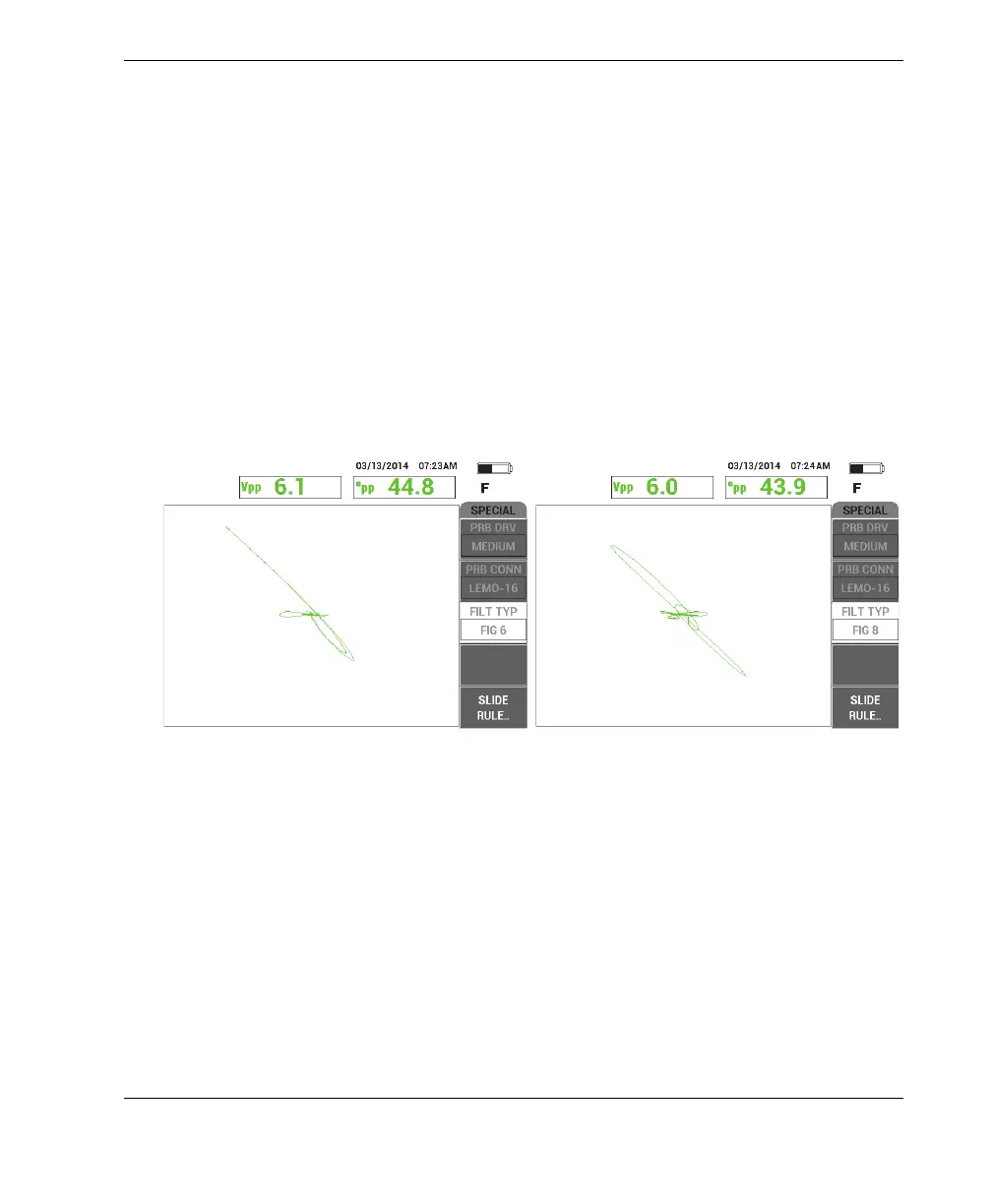

The default filter type is a Figure 6 (FIG 6) signal, which has a needle-like shape and is

widely employed in the industry. This Figure 6 filter automatically adjusts the signal

phase in order to achieve the typical Figure 6 response, regardless of high and low

pass filter settings. This constant Figure 6 filter response enables much quicker and

easier tuning of the NORTEC 600 filter system, and it makes it possible to eliminate

unwanted signals rather than trying to achieve the proper signal shape.

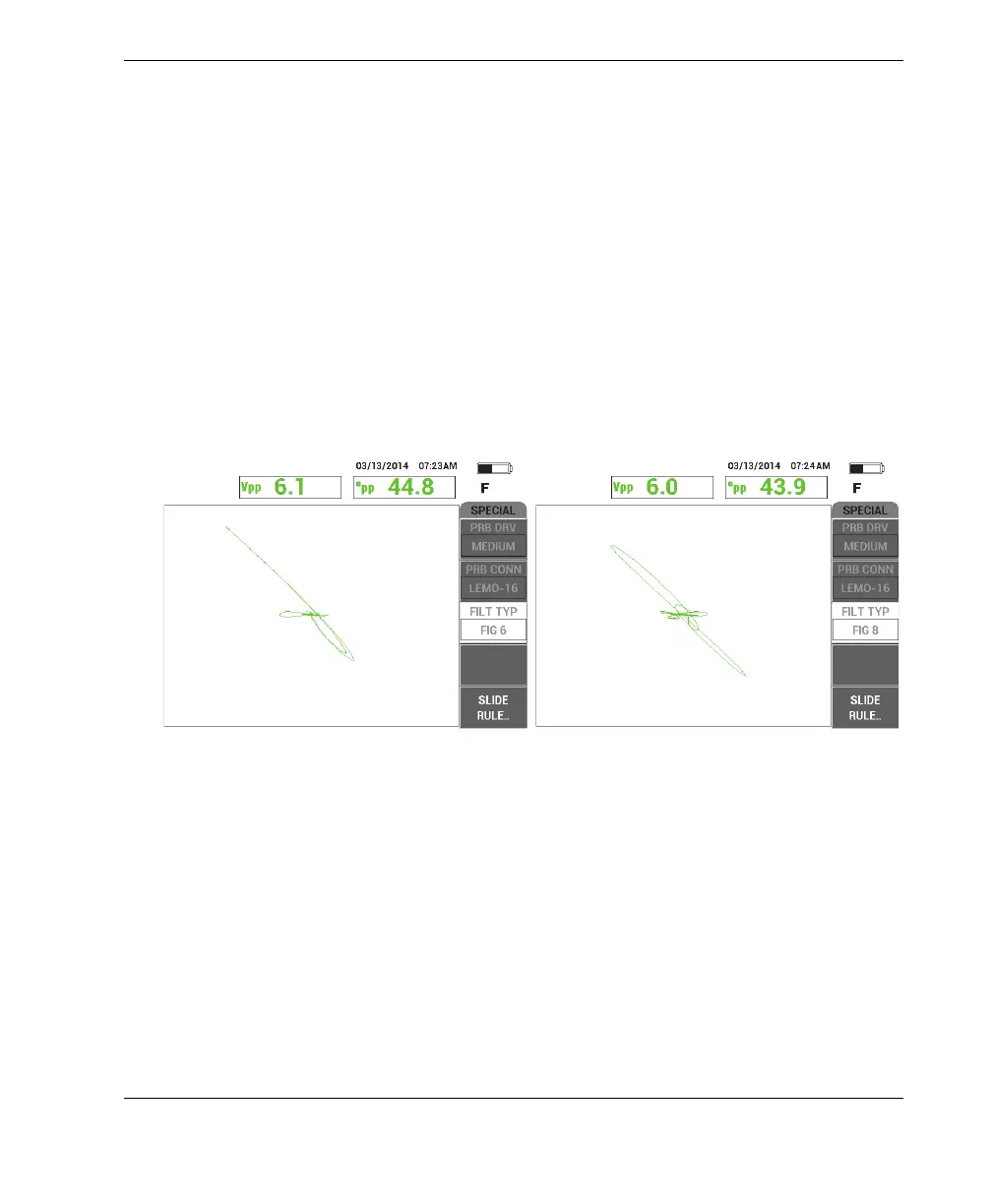

The Figure 8 (FIG 8) filter type is generated using filters that are almost completely

nondistorting. This filter type is useful when using absolute rotating probes or in

special engine-inspection applications. The Figure 8 filter is also the default filter type

for nonrotating applications such as surface inspection.

Figure 5-21 on page 135 shows the Figure 6 response on the left and the Figure 8

response on the right. Both images have been obtained using the same probe in an

aluminum hole with very similar gain and angle settings.

Figure 5‑21 Comparing the Figure 6 (left) and Figure 8 filter signals

By setting LINK to ON, you can enable the dynamic high and low pass filter settings

while you adjust RPM to maintain the signal response.

5.1.3 Detecting Sub-Surface Cracks at Very Low Frequency — All

NORTEC 600 Models

This section contains a general procedure for detecting sub-surface cracks at fastener

locations in aircraft lap joints. This procedure can easily be adapted to thicker skins

(or materials) by employing a bigger ring probe and lower frequency.

Loading...

Loading...