DMTA-10040-01EN, Rev. E, February 2018

Using the Instrument 229

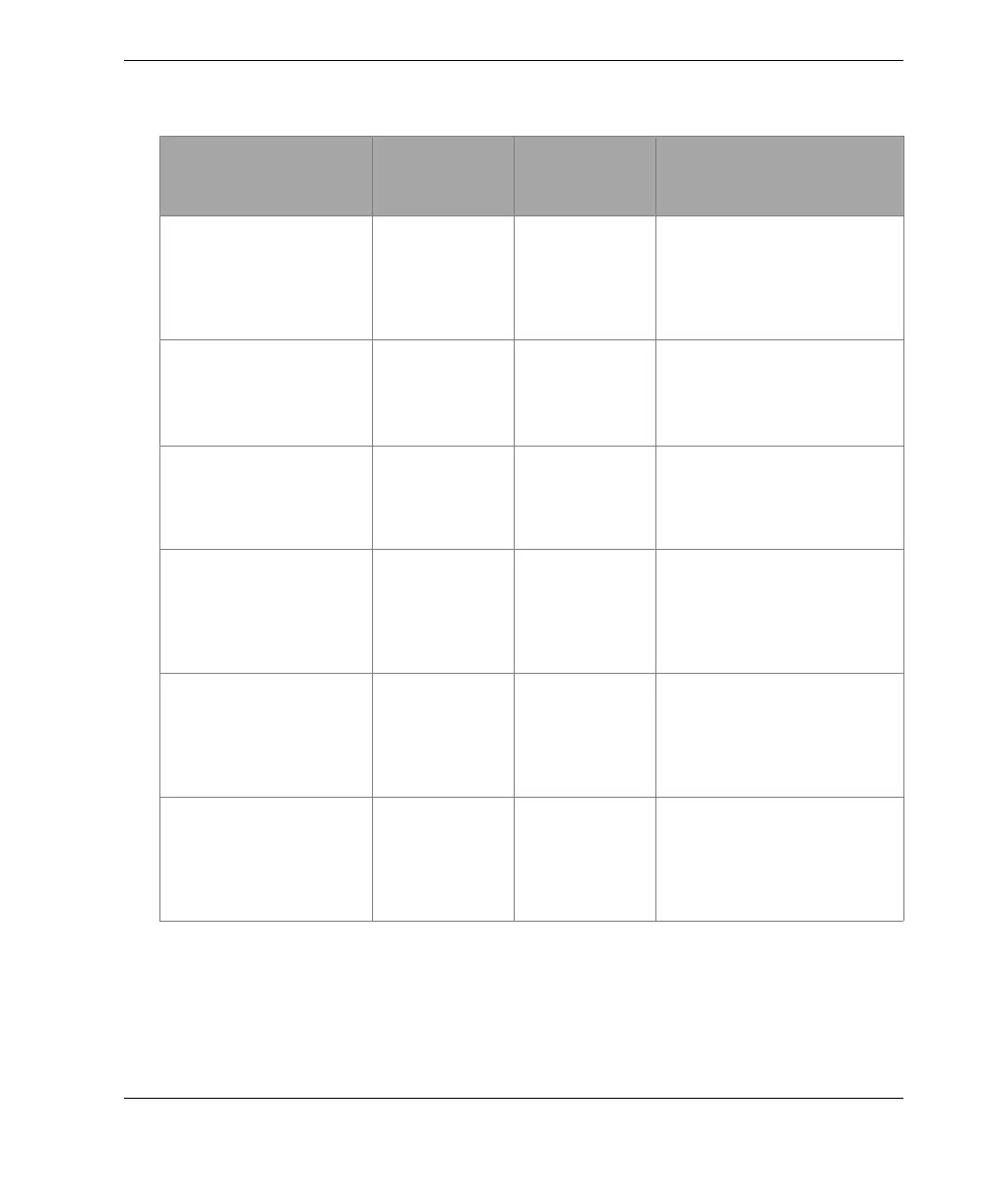

Table 6 Recommendations for heat exchanger tubing applications

Tube material and type

Compatible

magnetic

technology

Compatible

Olympus tube

probe series

Remarks

Nonferromagnetic

(copper, brass,

aluminum, titanium,

300 series stainless steel,

Inconel, and others)

Eddy current

(ECT)

TEA/TEB,

TEE/TEF, TEG,

TEK/TEL

Virtually any bobbin-type

probe from Olympus or

other manufacturers can be

used.

Ferromagnetic (carbon

steels, nickel)

Remote field

(RFT)

TRS, TRX Use single exciter (TRS) for

erosion/corrosion.

Use dual exciter (TRX) for

pitting.

Mildly ferromagnetic

(Monel, 400 series

stainless steel, Duplex

stainless steel)

ECT or RFT TEO or TRX Higher frequency TRX dual

exciter probes are

recommended; they are

easier to use and procure.

Carbon steel finned

tubing (typically finned

air-coolers; tubes are

wrapped with

aluminum fins)

Near field

(NFT)

TRD RFT will NOT work because

the entire magnetic field is

absorbed in the fins.

Stainless steel finned

tubing (typically with

aluminum fins

wrapped around tube)

Eddy current

(ECT)

TEA/TEB,

TEE/TEF

Set frequency high enough

(500 kHz) to inspect internal

surface only. No penetration

is possible. An alternative is

IRIS (ultrasound).

Air conditioner (A/C)

[chiller or evaporator]

finned copper tubing

Eddy current

(ECT)

TEA/TEB,

TEC/TED

Regular bobbin probes are

often used; however, A/C

probes or similar competing

models will detect

circumferential cracking.

Loading...

Loading...