DMTA-10040-01EN, Rev. E, February 2018

Chapter 5168

2. Ensure that the scanner motor is turned off before initial instrument nulling, place

the probe in the good hole, and then press the A-LIFT NULL key ( ).

3. Place the probe in the hole with EDM notches, and then adjust the index axis so

that the probe rotates freely next to a defect area.

Leave the scanner in the R position (rotation).

4. Turn on the scanner motor, and then press the MAIN FILTER menu key ( )

twice, and set the SCAN RPM (E key) to 240.

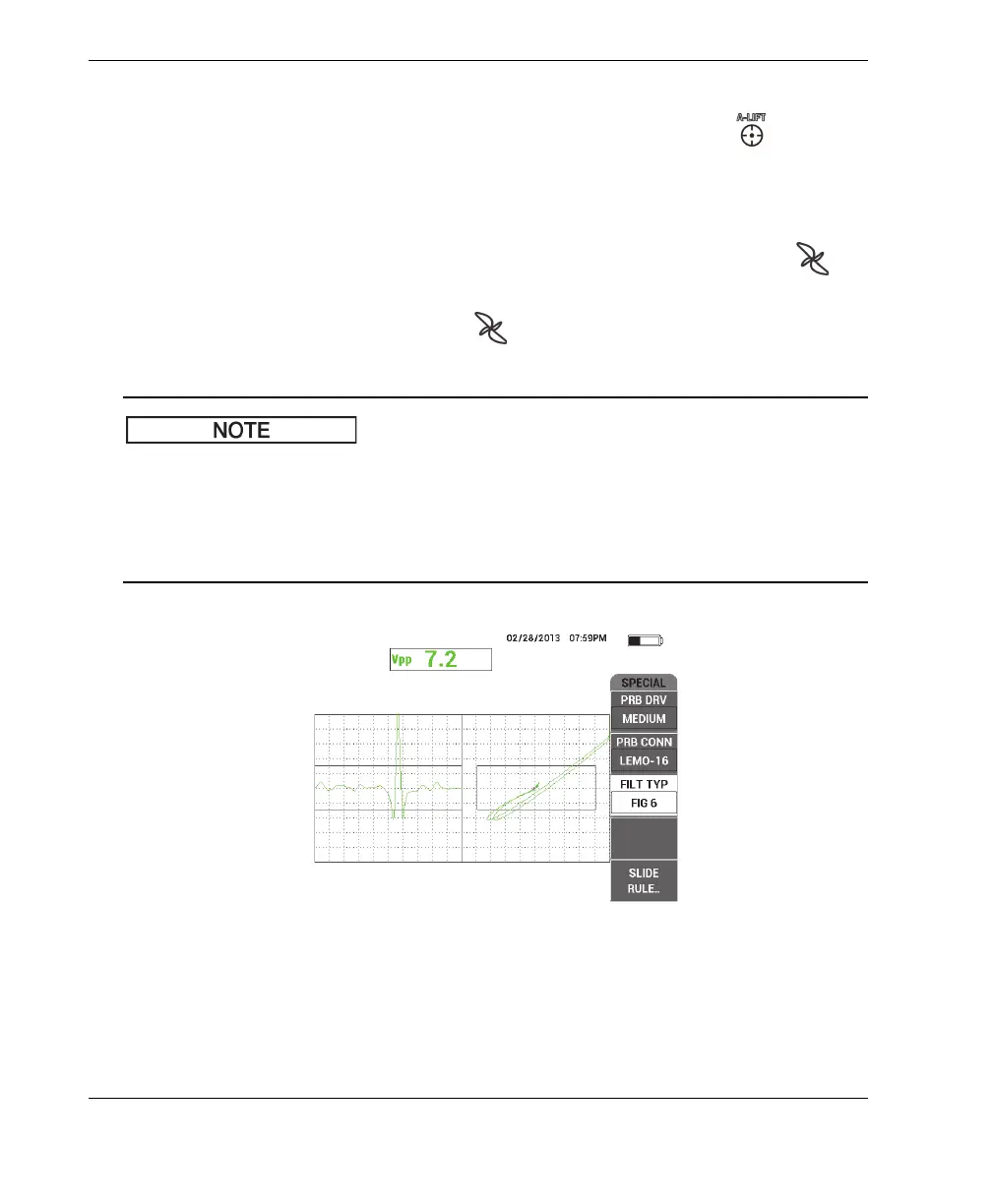

5. Press the MAIN FILTER menu key ( ), and then change the FILT TYP (C key)

to FIG 6 (see Figure 5-64 on page 168).

This procedure uses the Figure 6 filter setting. Olympus recommends using the

Figure 6 filter setting unless an absolute probe is being used, in which case the

Figure 8 filter setting might provide better performance. For more information about

the Figure 6 versus Figure 8 parameters, see “Inspecting Fastener Holes with a

Rotating Scanner — NORTEC 600S and NORTEC 600D Models” on page 126.

Figure 5‑64 The Figure 6 filter

Loading...

Loading...