Toner supply (sub-hopper - development unit)

The sub-hopper can hold Bk: 24.7 cc (equivalent to 230 sheets of 5% chart), or Color: 19.3 cc

(equivalent to 150 sheets of 5% chart) of toner.

Toner which has fallen into the sub-hopper is homogenized by an agitator (Sheet: 2 for BK, 1 for each

color).

After being horizontally transported by the coil, toner in the sub-hopper falls directly into the

development unit.

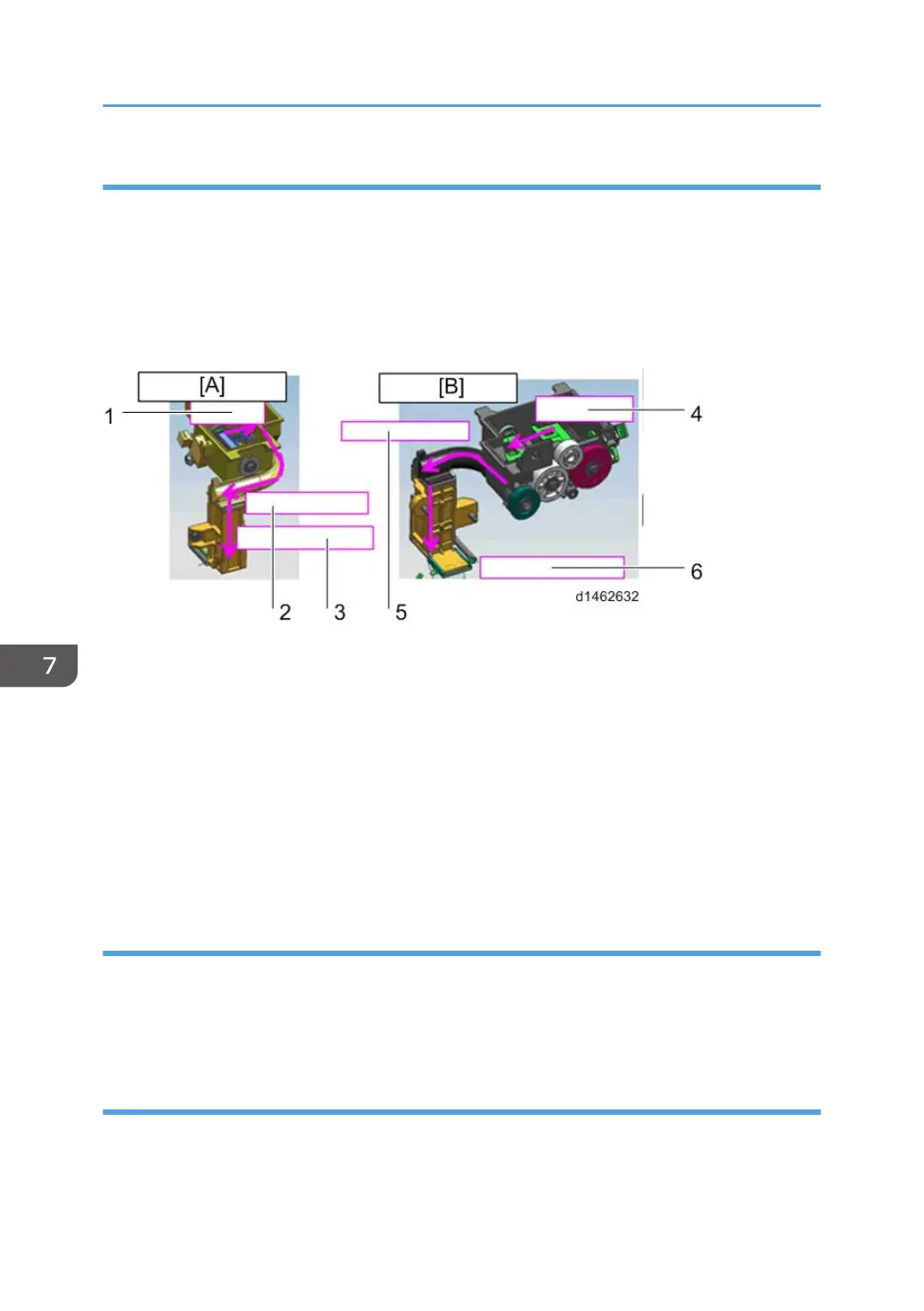

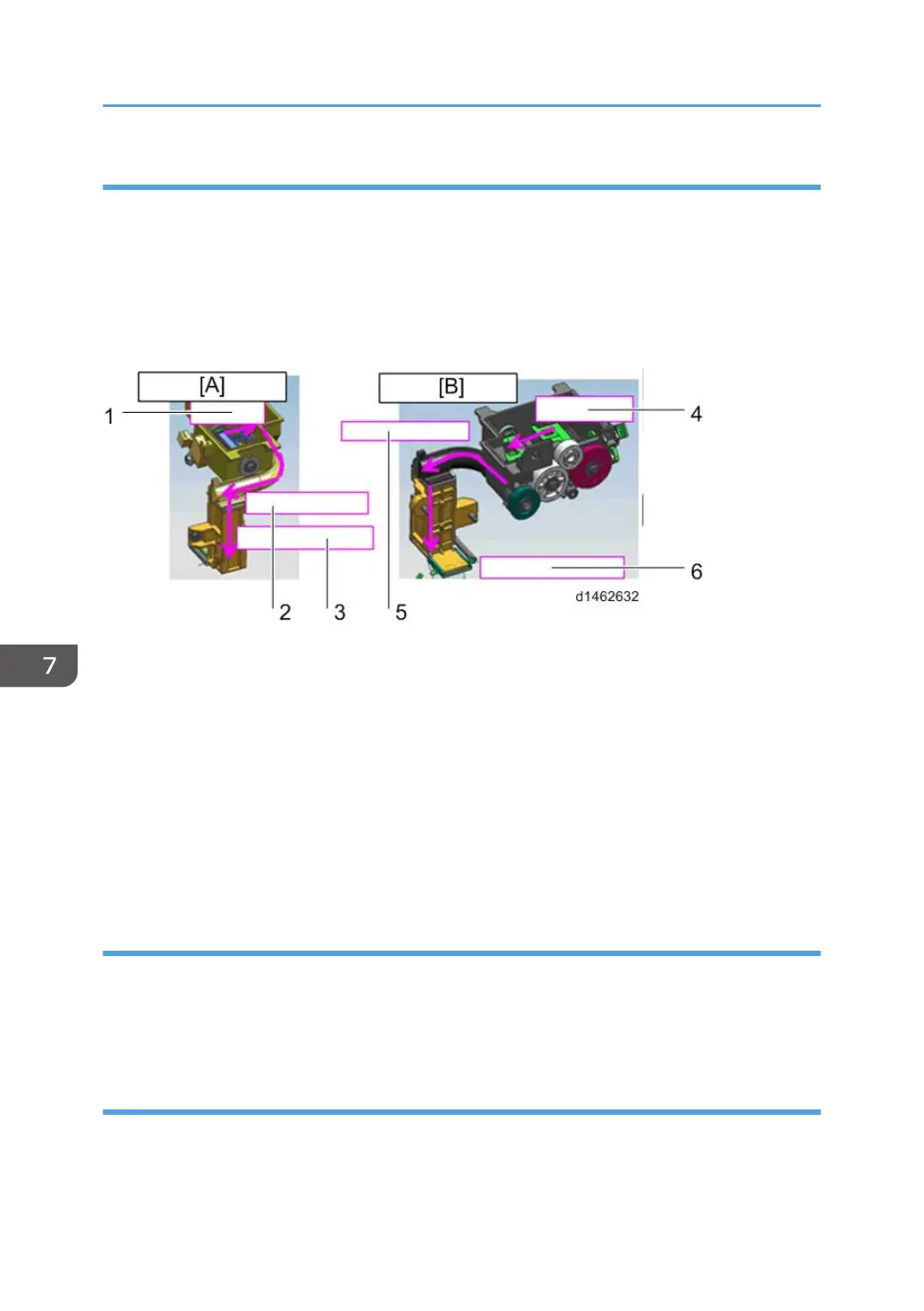

[A]: Sub-hopper: CMY

[B]: Sub-hopper: Bk

1. Transport by the sheet

2. Transport horizontally by the coil

3. Vertical drop to the Development unit

4. Transport by the sheet

5. Transport horizontally by the coil

6. Vertical drop to the Development unit

Drive

To shorten the recovery time after bottle replacement, the toner cartridge and sub-hopper are driven

separately.

The sub-hopper is driven by a stepping motor to reduce supply variations.

Toner near end/end detection

In this device, there are two types of toner near end status.

The detection conditions and detection operation for each status are shown in the following table.

7. Detailed Descriptions

1246

Loading...

Loading...