SAMPLE PROCESSING

Sysmex SF-3000 Operator's Manual -- Revised September 1995 2-3

2. START-UP PROCEDURE

2.1 Operator Checks

1 . Reagents

Make sure that there is a sufficient amount of reagent for the day's samples.

If the amount is insufficient, prepare replacement reagent. If reagent runs out

during an analysis, the system automatically stops and alerts the operator to replace

the reagent. Analysis cannot be resumed until replacement is complete. Replace

the reagent container by referring to the procedures in Chapter 5: Maintenance and

Supplies.

The following shows the approximate number of cycles that can be analyzed per

container of reagent.

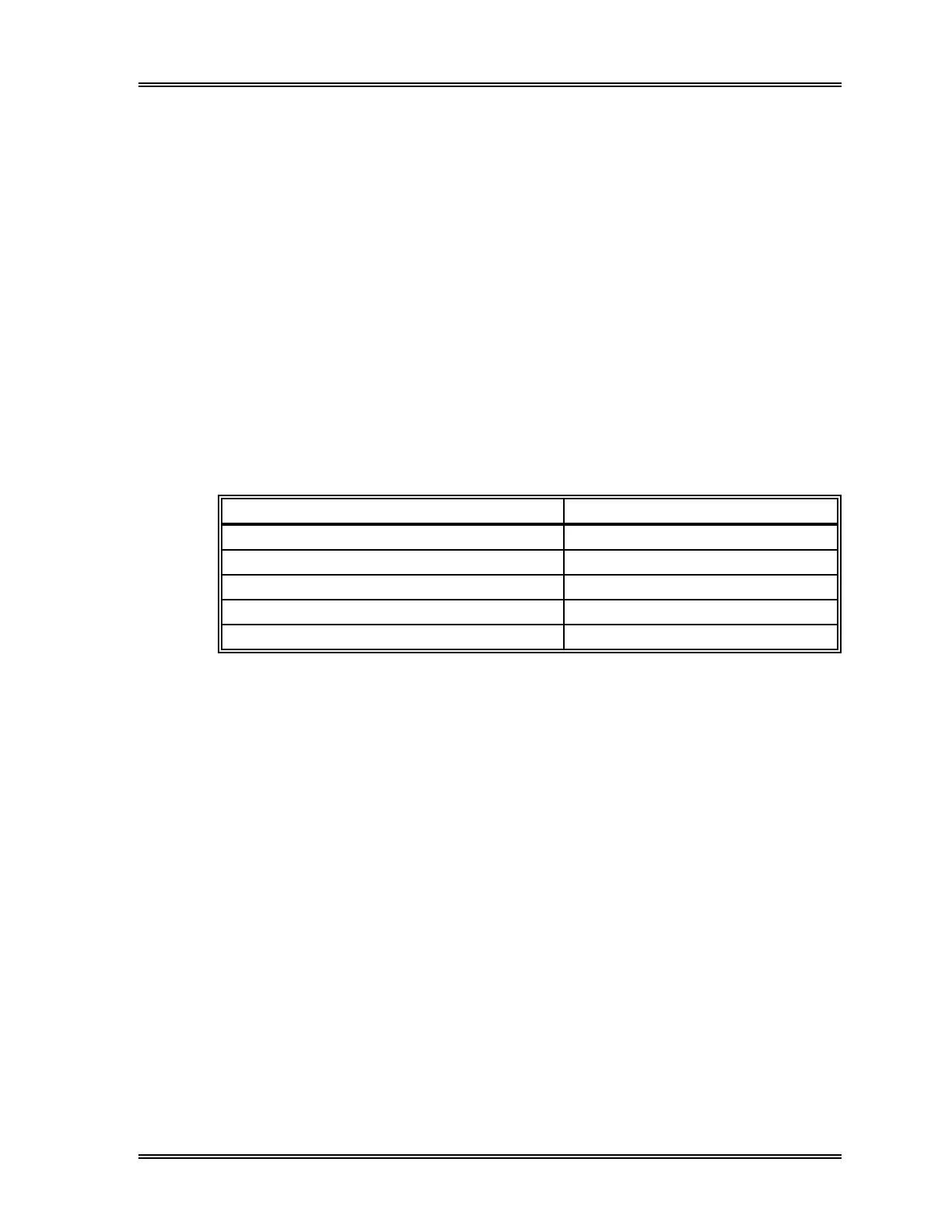

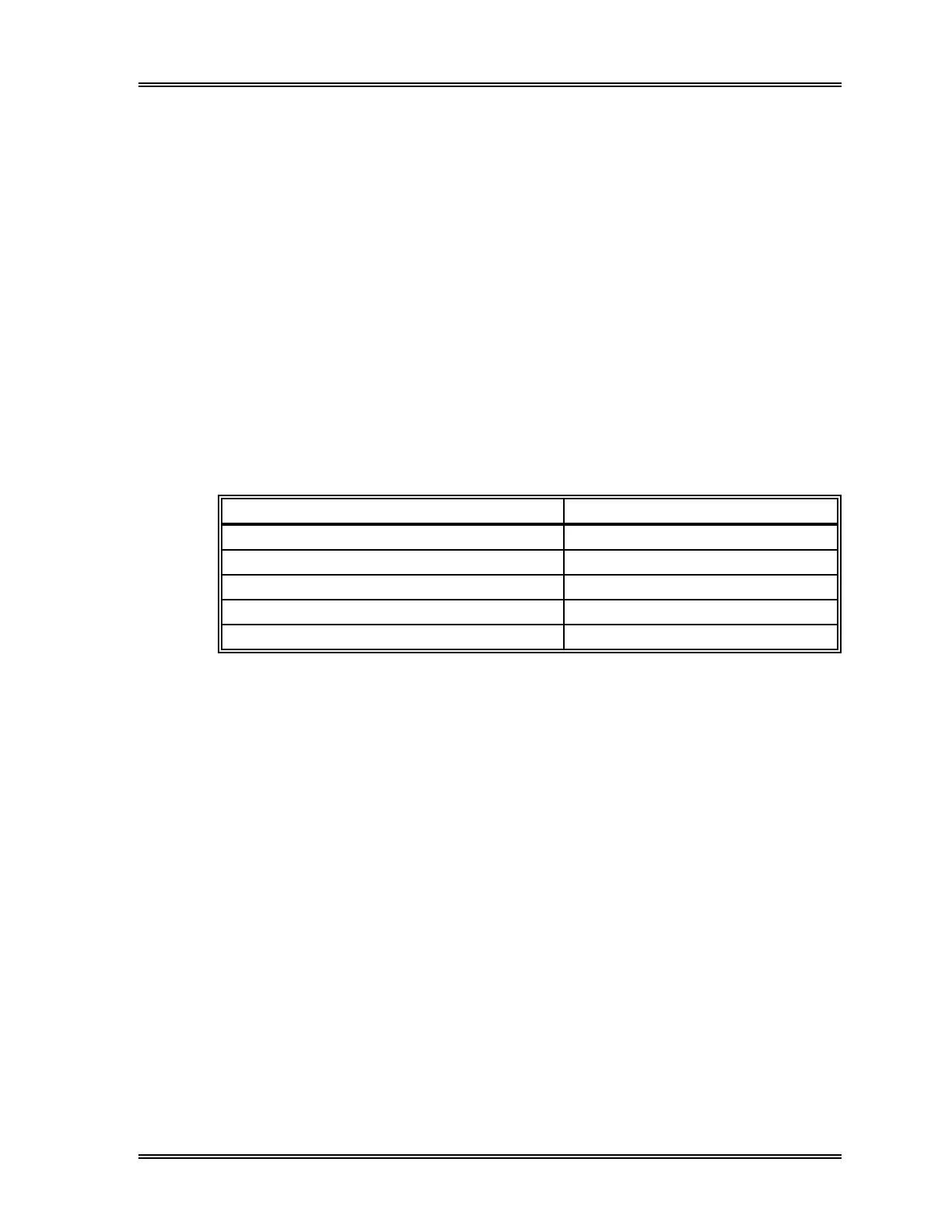

Table 2-2: Cycles Analyzed per Reagent Container

Reagent Number of Cycles Analyzed

CELLPACK : Diluent 380 cycles per 20 L container

STROMATOLYSER-FB : BASO Reagent 2,500 cycles per 5 L container

STROMATOLYSER-FD (I) : 4Diff Reagent 2,500 cycles per 5 L container

STROMATOLYSER-FD (II) : 4Diff Reagent 2,500 cycles per 500 mL bottle

SULFOLYSER : HGB Reagent 1,000 cycles per 500 mL bottle

2 . Printer Paper

Make sure that there is sufficient printer paper for the day's samples.

3 . Equipment

Check the tubing and cables. Make sure that the tubing is not bent and the power

cord is securely plugged into the power outlet.

4 . Sampler

Make sure that there are no racks on the analysis line. Remove any rack from the

line. Make sure that the left and right rack pools and analysis line are clear.

5 . Waste Fluid

Discharge any waste fluid that has been collected in the pneumatic unit drain trap

and waste container (if applicable).

Loading...

Loading...