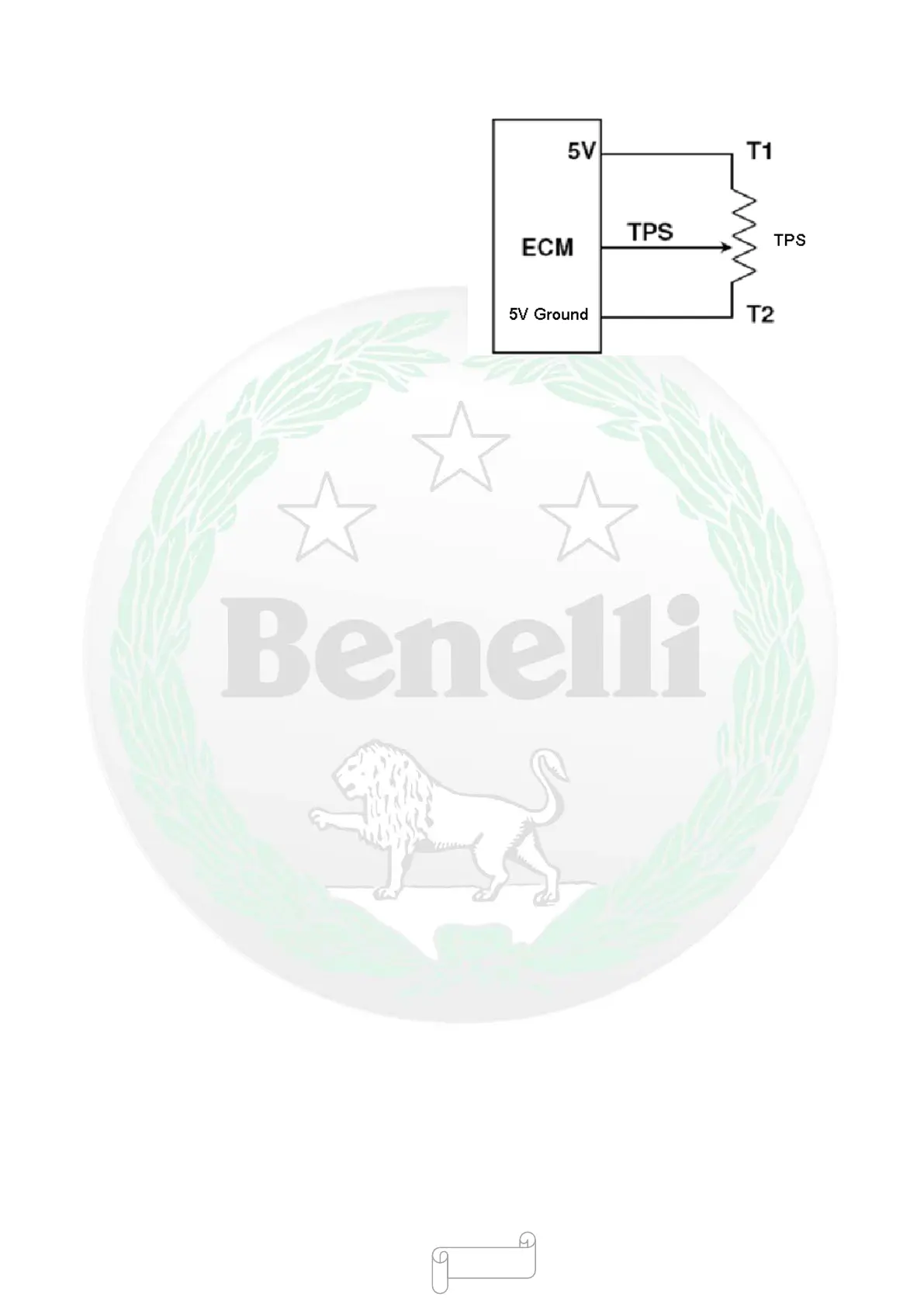

Throttle Position Sensor:

Reference voltage: 5±0.1VDC

Resistance between T1 and T2: 3k-12kΩ

Air Control Valve of Idle Speed:

Working voltage: 7.5-14.2VDC

Winding resistance: 53Ω±10%

Winding inductance: 33mH±20%

Working Environment of Throttle

Normal working temperature: -30-120°C

Disassembly of Throttle

Turn off the power switch

Disconnect the negative electrode connection of

storage battery

Disconnect the connectors of throttle position

sensor, stepper motor, intake temperature /

pressure sensor (if it has been installed at throttle

assembly)

Remove throttle wire

Remove the hose connected with air filter and

intake manifol

Cleaning Method of Throttle

Clean throttle

body using carburetor cleaner (3M

product is recommended). Spray cleaner at the inner

wall of throttle

body, and gently remove dust and

carbon depo

sit and other items using a brush. Be

careful to prevent the bypass airway from being

blocked by dirt.

Installation of Throttle

Note the following items for the steps to install

throttle body:

Adjust throttle wire

Ensure that all moved parts have been

installed in place, such as stepper motor

assembly

Install connection screw

Precautions for Installation of Throttle

Do not immerse the throttle position sensor into

the liquid.

- 155 -

Loading...

Loading...