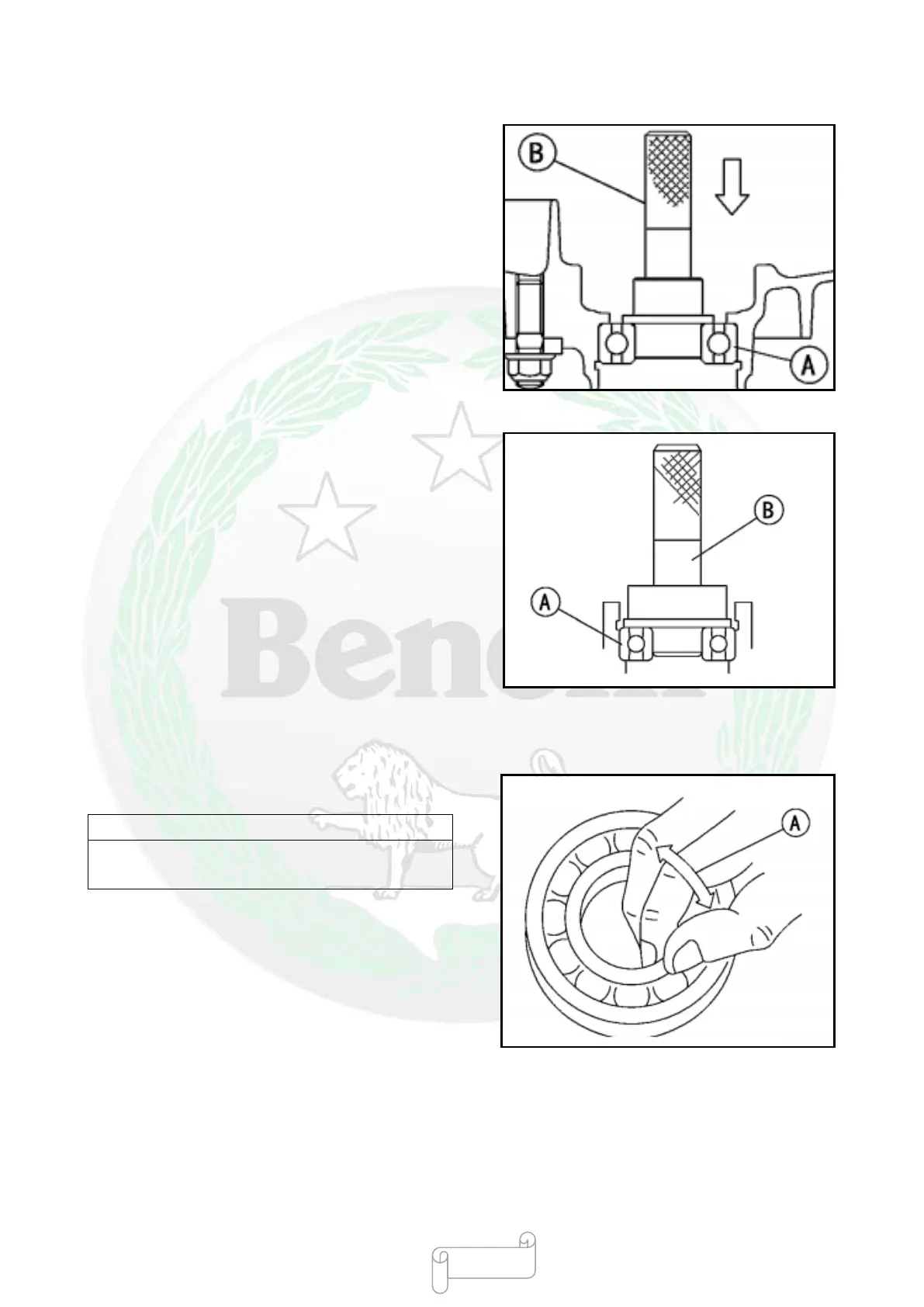

Disassembling Shaft Sleeve Bearing

●Knock out the bearing [A] from one side of wheel.

Special Tools—

Complete Set of Tools for Installing

Bearing:

Installing Shaft Sleeve Bearing

●Replace one new bearing.

●

Press bearing [A] towards the inside, until it reaches

the top.

Special Tools—

Complete Set of Tools for Installing

Bearing [B]:

●Apply high-temperature grease to the bearing.

●Replace one new oil seal.

●

When pressing it into the new oil seal, the sealing

surface should be aligned at the end of hole.

○Apply high-temperature grease to the edge of oil seal.

Special Tools—

Complete Set of Tools for Installing

Bearing:

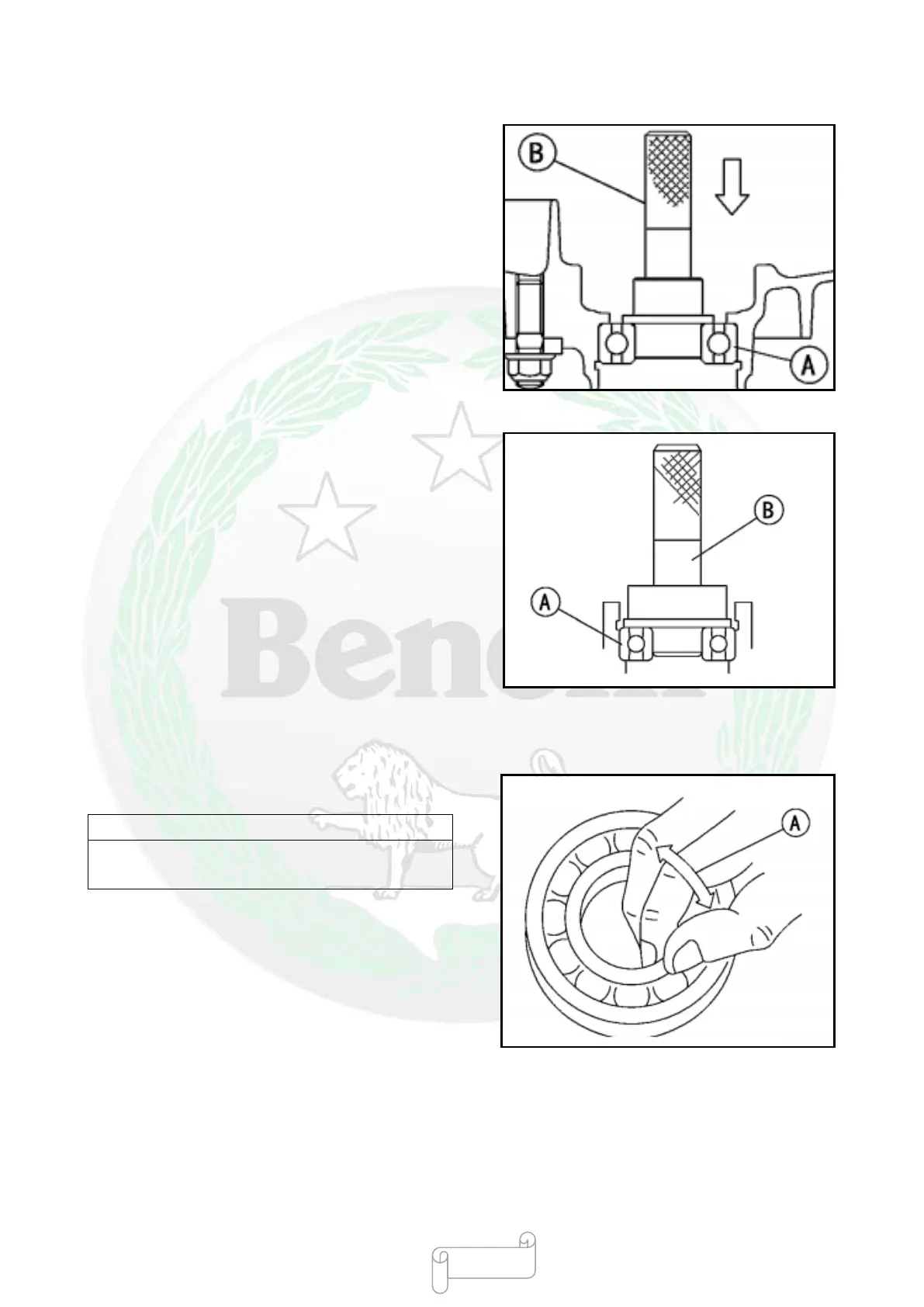

Checking Shaft Sleeve Bearing

●As the shaft sleeve bearing error is very small,

generally it is unable to measure the clearance.

○Do not remove any bearing for check, because the

bearing must be replaced with one after removal.

●If it needs to check whether there is an axial clearance

in the bearing, it is jammed or blocked during the

rotation, please rotate each bearing in the hub back and

forth [A]!

★

If the bearing cannot rotate smoothly, please replace

the bearing!

Lubrication of Shaft Sleeve Bearing

●Add high-quality bearing grease to bearing. Rotate

the bearing for several times by hands to ensure that

the grease distribution in the bearing is uniform.

- 307 -

Loading...

Loading...