disassembling fuel line, in order to avoid the risk

of occurrence, the blocking device at the fuel pipe

should be used for blockage.

After maintenance is completed, please ensure that

the fuel line and clamp are properly installed.

After maintenance is completed, check system oil

leakage according to the provisions of “Fuel

Leakage Check Process”.

After maintenance is completed, connect the

negative electrode of storage battery, please ensure

that there is sufficient fuel in the fuel tank when

the fuel pump is running.

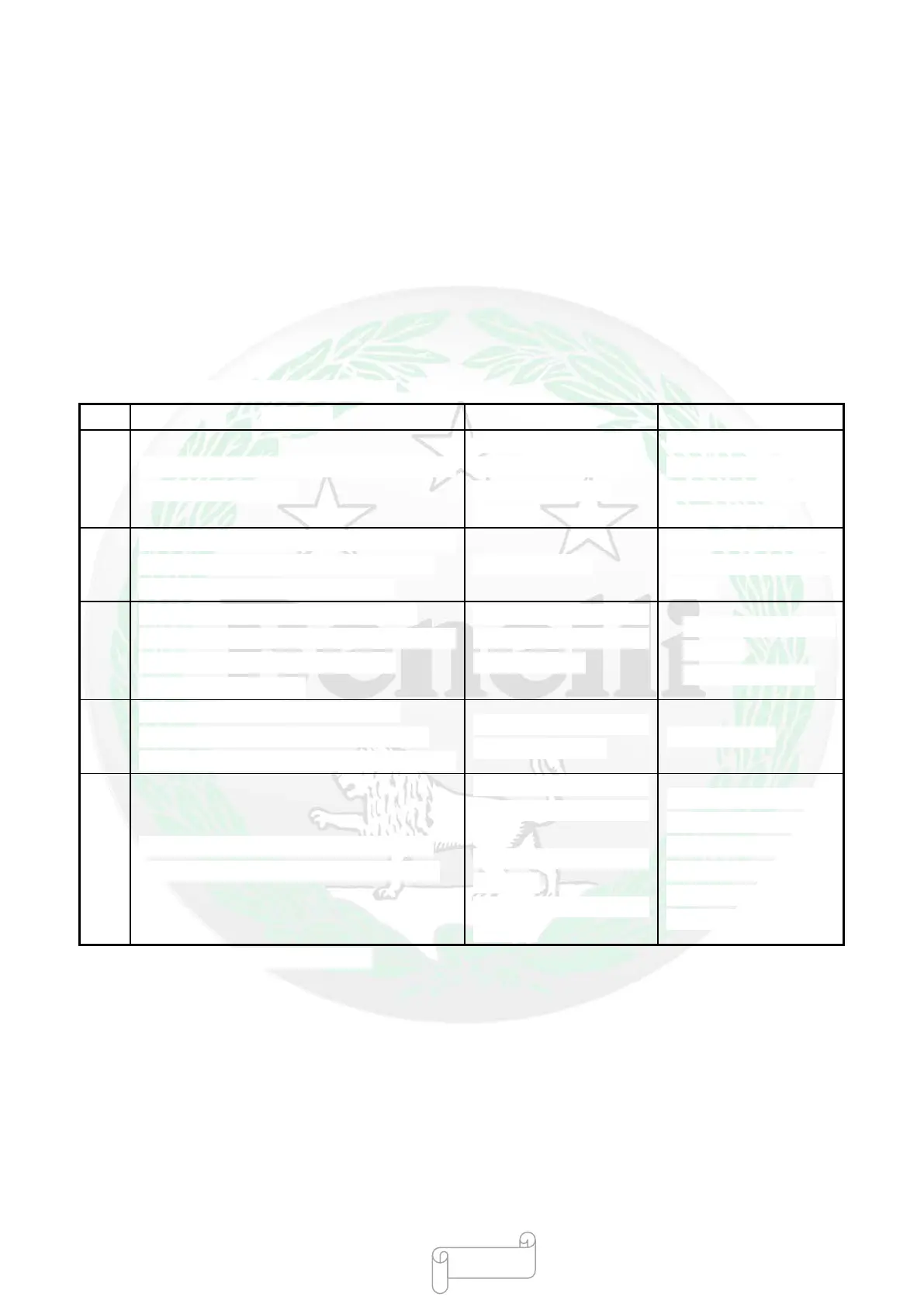

Fault Diagnosis of Fuel Pump Assembly:

1

After ingnition key

will run for 3 seconds.

fuel pump is running,

please go to Step 4

If you cannot hear that

the fuel pump is

running, please

conduct Step 2.

2

Disconnect the connector of fuel pump, and

check whether the supply voltage of fuel

pump is within the range of 10-14V

Conduct Step 3

Check the power

supply circuit of fuel

pump

3

Supply 12V DC current to fuel pump.

Ensure that there is sufficient oil in the tank,

to prevent dry running of fuel pump

from fuel pump to ECU

2. Check ECU

1.

harness

2. Check fuel pump

4

Check whether the front fuel supply

pressure of nozzle is within the range of

220-270kpa when engine is in idle running.

running normally

Conduct Step 5

5

Detect whehter fuel pipe way pressure is

less than 220kpa using oil pressure gauge.

1. Check whether there

is leakage at fuel pipe

joint

position

3. Check pressure

regulator

fuel filter is blocked

pipe is bent and twisted

regulator

Disassembly of Fuel Pump Assembly:

Refer to “Fuel Pressure Release Process” to

release the fuel pressure in the fuel line.

Disconnect the negative electrode line of storage

battery.

Disconnect fuel pump assembly harness

connector.

Remove the remaining fuel from the fuel tank and

store it in a suitable container, to ensure safety and

reduce contamination.

Remove the fuel tank from the motorcycle.

- 150 -

Loading...

Loading...