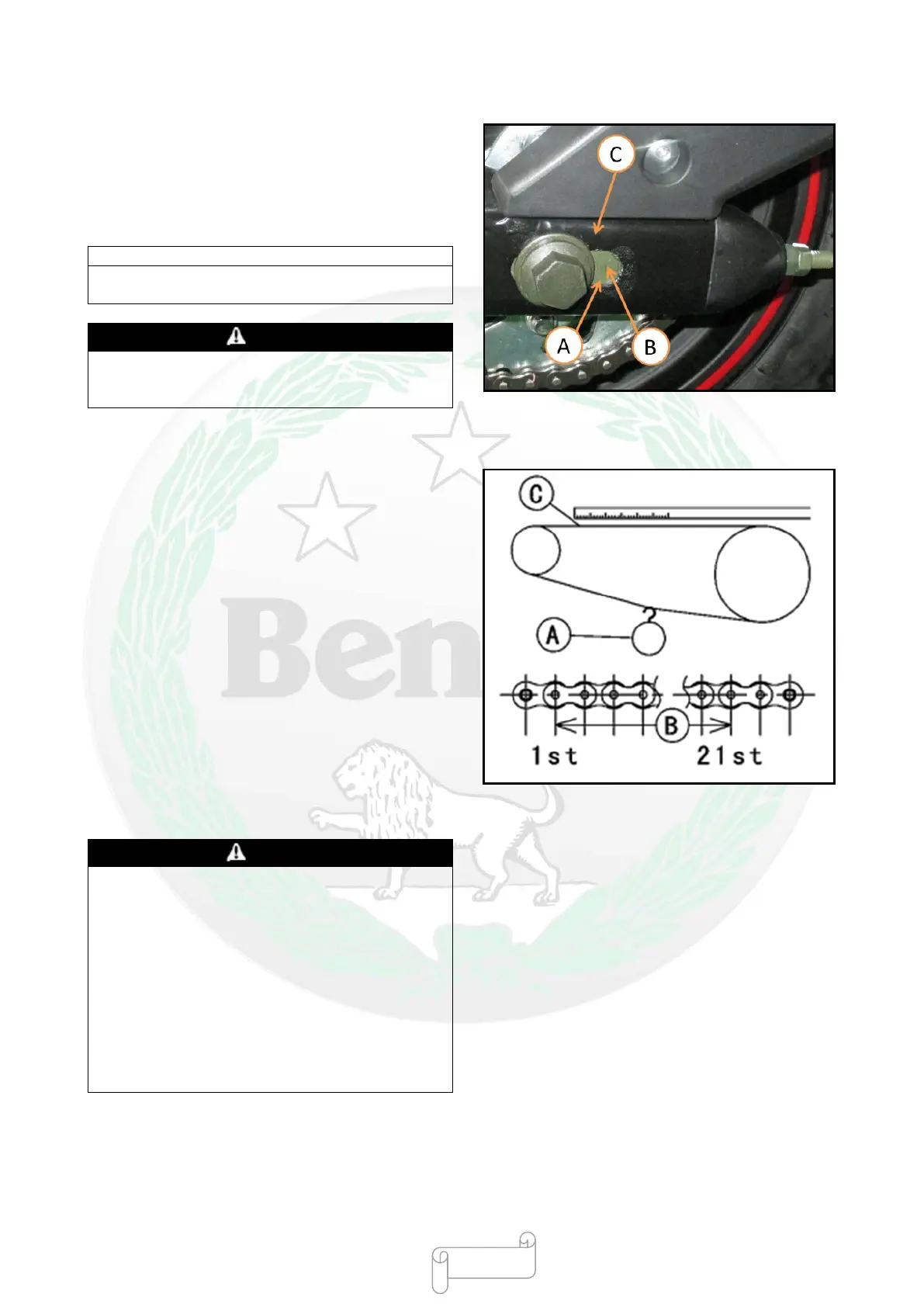

Checking Wheel Alignment

●Check whether the position of the concave scale line

[B] on the right chain adjuster [A] on the rear swing

arm [C] is the same as that of concave scale line on the

left chain adjuster.

★

If they are not aligned, adjust the slackness of drive

chain and align the wheel alignment (see “Adjusting

Slackness of Drive Chain”).

○Check whether the wheel alignment is accurate

with the ruler or rope.

If the wheels are not aligned, the wheels will

be worn out abnormally and dangers may be

caused during riding.

Checking Wear of Drive Chain

●Remove the chain guard (see “Disassembling Drive

Chain” in “Final Drive Mechanism” chapter).

●Rotate the rear wheel and check whether there are

damaged rollers, loose cotter pins and chain meshes.

★

If any abnormal situation is found, replace the drive

chain.

★If the drive chain looks dry, add the lubricant.

●Hang a 6kg

weight on the drive chain to tighten the

drive chain.

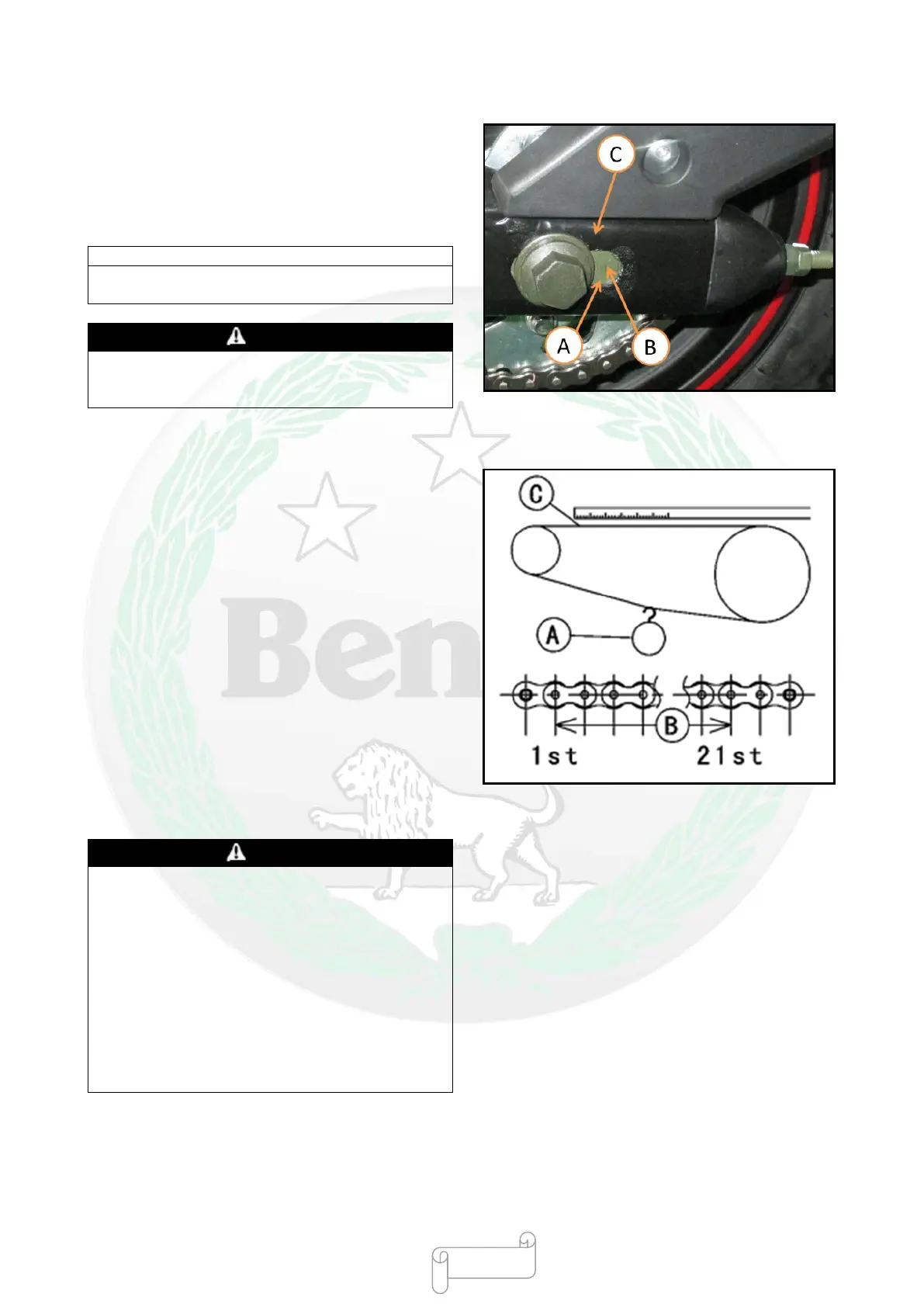

●Measure the length of the 20 links [B] (from the

center of the first cotter pin to the center of the 21

st

cotter pin) of the drive chain of the straight part [C]. As

the drive chain is

worn unevenly, the measurement

shall be carried out in several different parts.

★

If any measured value exceeds the use limit, the

drive chain needs to be replaced. Replace the front and

rear sprockets simultaneously.

Length of 20 chain meshes of drive chain

Standard: 254 -254.7 mm

Use limit: 259.5 mm

If the wear of drive chain exceeds the use limit,

the drive chain must be replaced, otherwise

dangers may be caused during riding. If the drive

chain is broken or falls off from the sprocket, the

spr

ocket of engine will be tripped or the rear

wheel will be locked, which will cause serious

damage to the motorcycle and make it be out of

control.

To ensure safety, the standard drive chain

must be used. The standard drive chain is a chain

without meshes w

hich cannot be cut off during

installation.

Standard Drive Chain

Model: 428HG

Number of chain meshes: 116

- 70 -

Loading...

Loading...