Chapter 5 Parameters Definition

142

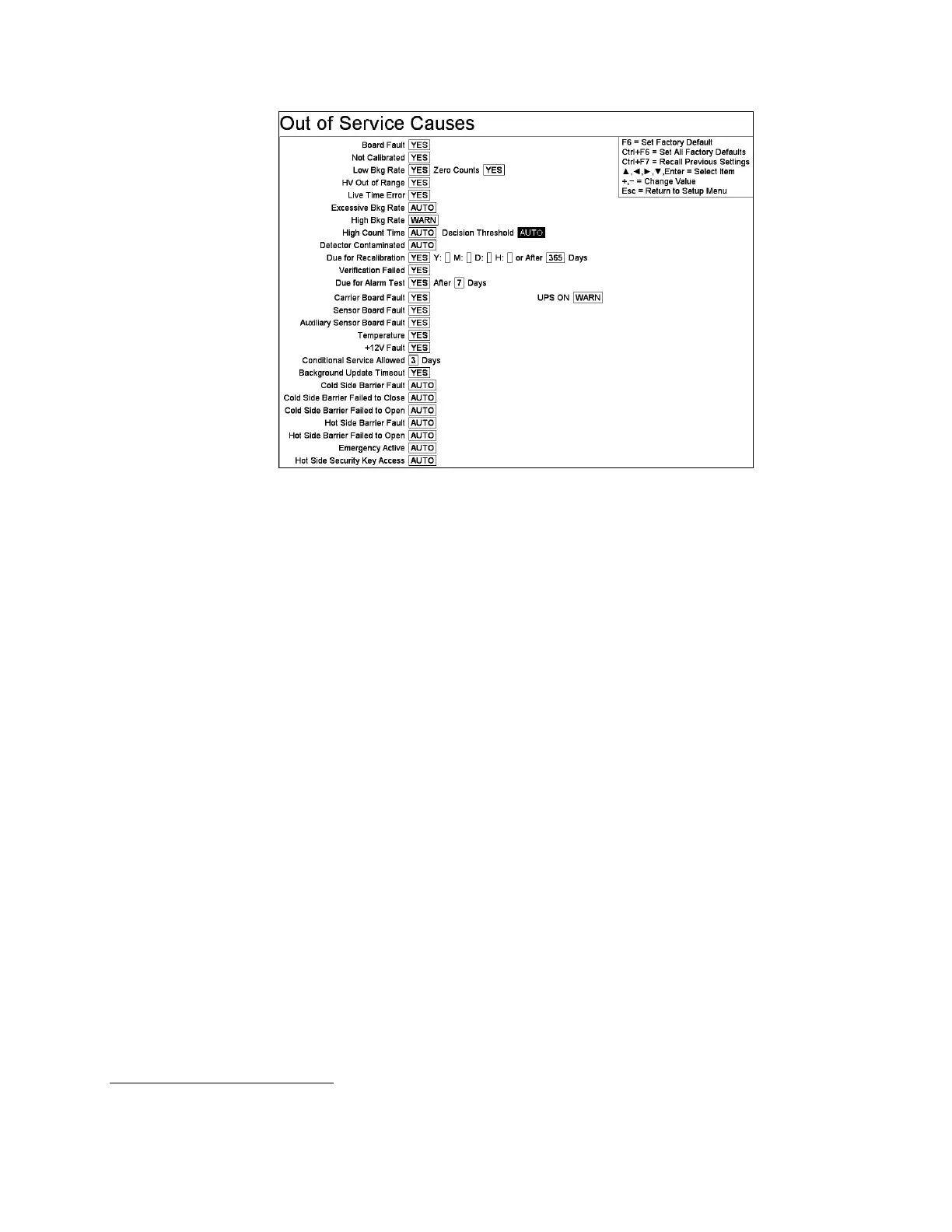

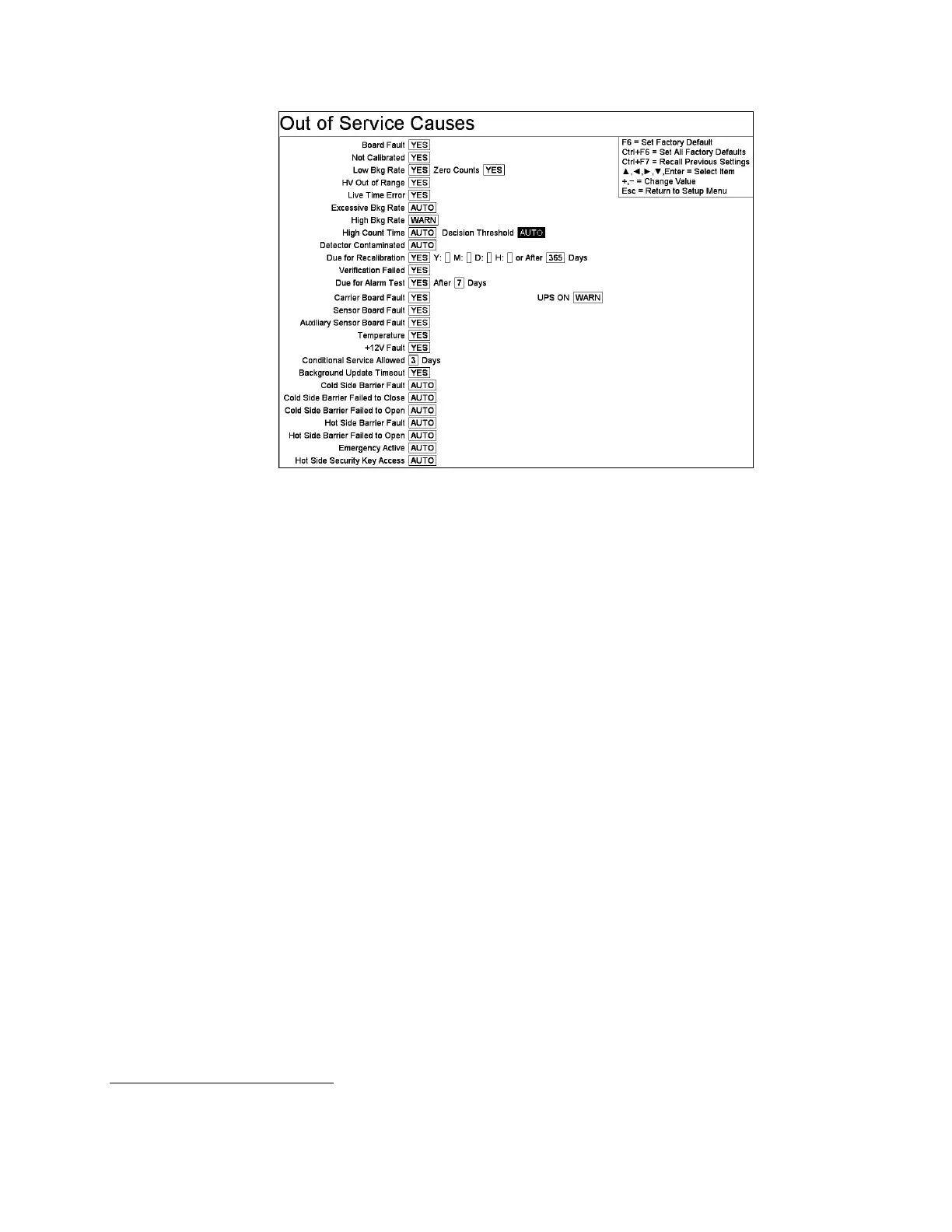

Figure 64 The Out of Service Causes Screen

Fixed Line Items [Yes]

The following conditions always cause an Out of Service condition. It is possible,

however, to return a unit to service with (detector) Board Fault(s) by putting those

detectors in “Determining Faults”, as explained on page 223.

Board Fault

8

: A (detector) board fault is flagged if it fails to respond as expected

when queried by the Carrier Board. This could be the result of a failed LED

(address) Board, an incorrectly set detector board ID switch, a disconnected cable,

etc.

Not Calibrated: Can also be known as a calibration fault. A detection zone is

considered to be not calibrated if its efficiency is <0.1% and the Sum Zone All < 1%.

This condition can be corrected by calibrating the zone using the F3 – Calibration

screen (page 121). In addition, if either the High Voltage (HV) or the Discriminator

Voltage (DV) has changed since the last calibration a Calibration fault occurs.

HV Out of Range

8

: The detector high-voltage supply is generated on the Detector

Board. It is regulated and set by a digital-to-analog converter (DAC). There is also a

built-in high-impedance voltmeter with an analog-to-digital converter (ADC) which

reads the voltage value for comparison with the set value. If the difference exceeds

2% of full scale, an error flag is set and the unit is taken out of service.

Live Time Error

8

: Whenever a pulse is detected, there is a dead time (5µs - 15 µs)

when the electronics are “busy” handling the pulse. Another pulse generated during

that time would not be counted and would be lost. A live time error would occur if

the live time for the count was zero or if the time was so small as to cause a negative

8

Board Fault, HV Out of Range, Live Time Error, Low Bkg Rate, Zero Counts, Excessive Bkg Rate, and High Bkg Rate

checks are applied to single detection zones only—not sum zones.

Loading...

Loading...