Reading 2D Codes (DPM)

214

FQ2-S/CH User’s Manual

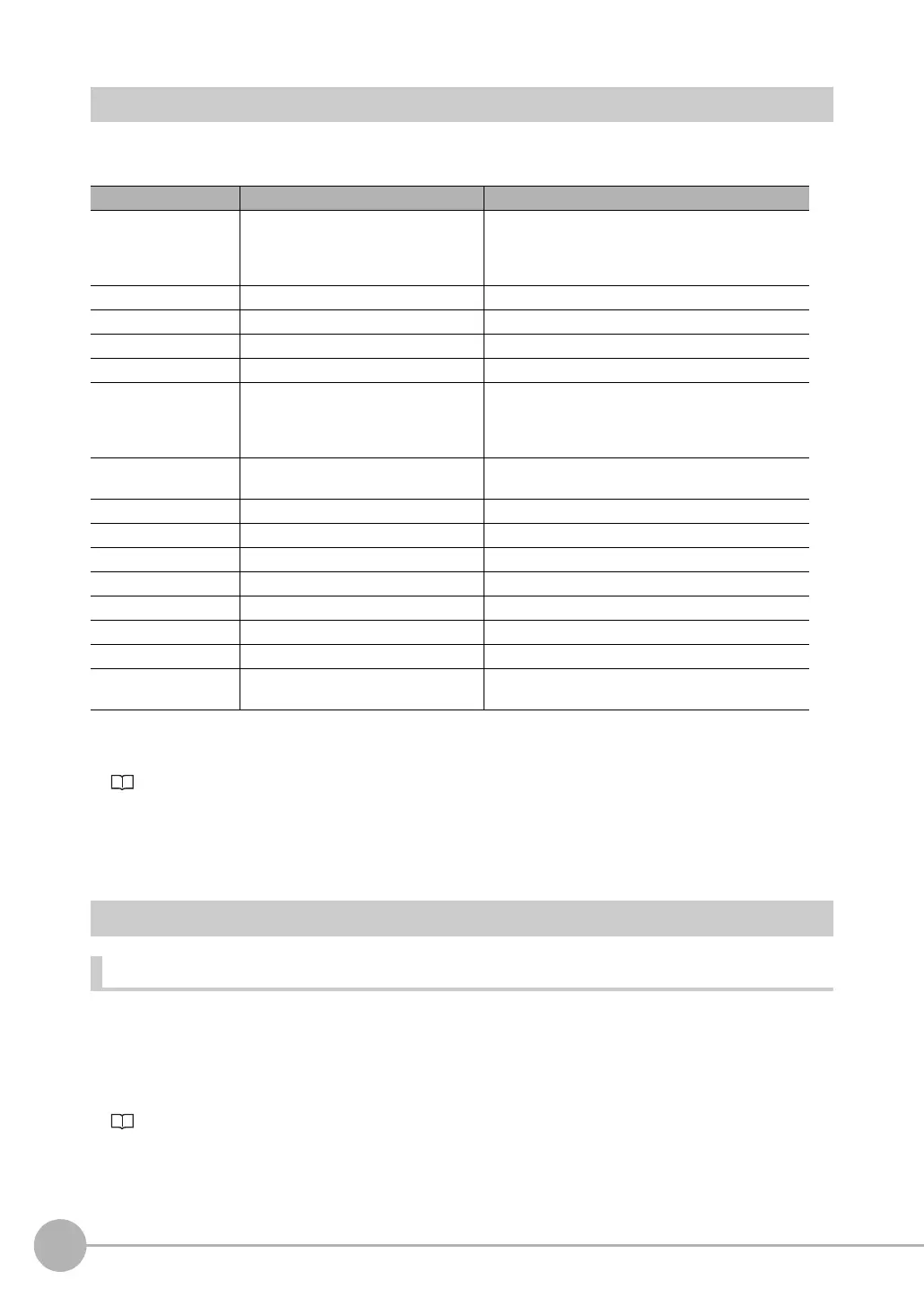

Inspection Data that Can be Logged

The following values can be logged as inspection data.

When logging data is output, the data is output in the order of the above table.

7-6 Logging Measurement Data and Image Data: p. 392

If an Error Occurs

If a teaching error occurs

If scanning of the 2D code fails, a teaching error message appears.

It is likely that low contrast caused unstable scanning.

Adjust the brightness to increase the contrast of the 2D code.

Adjusting the Brightness: p. 77

Inspection item Value range Description

Judgement

−2: No judgement (not measured)

0: Judgement is OK

−1: Judgement is NG

−16: Measurement timeout error

This is the judgment result from the measurements.

Contrast 0 to 100 Outputs the contrast.

Focus 0 to 100 Outputs the focus.

Cell recognition rate 0 to 100 Outputs the cell recognition rate.

Num. of char. 0 to 1024 Outputs the number of characters that were detected.

Index

−2: No verification pattern, or read-

ing error

−1: Verification is NG,

0 to 31: Master data No.

Outputs the index.

Cell size Depends on the size of the code. Outputs the number of pixels per cell of the scanned

code.

Overall quality 0 to 4 Outputs the evaluation value of overall quality.

Decode 0 to 4 Outputs the evaluation value of decode.

Cell contrast 0 to 4 Outputs the evaluation value of the contrast.

Cell modulation 0 to 4 Outputs the evaluation value of cell modulation.

Fixed pattern damage 0 to 4 Outputs the evaluation value of fixed pattern damage.

Axial nonuniformity 0 to 4 Outputs the evaluation value of axial nonuniformity.

Grid nonuniformity 0 to 4 Outputs the evaluation value of grid nonuniformity.

Unused err. Corr. 0 to 4 Outputs the evaluation value of unused error correc-

tion.

Loading...

Loading...