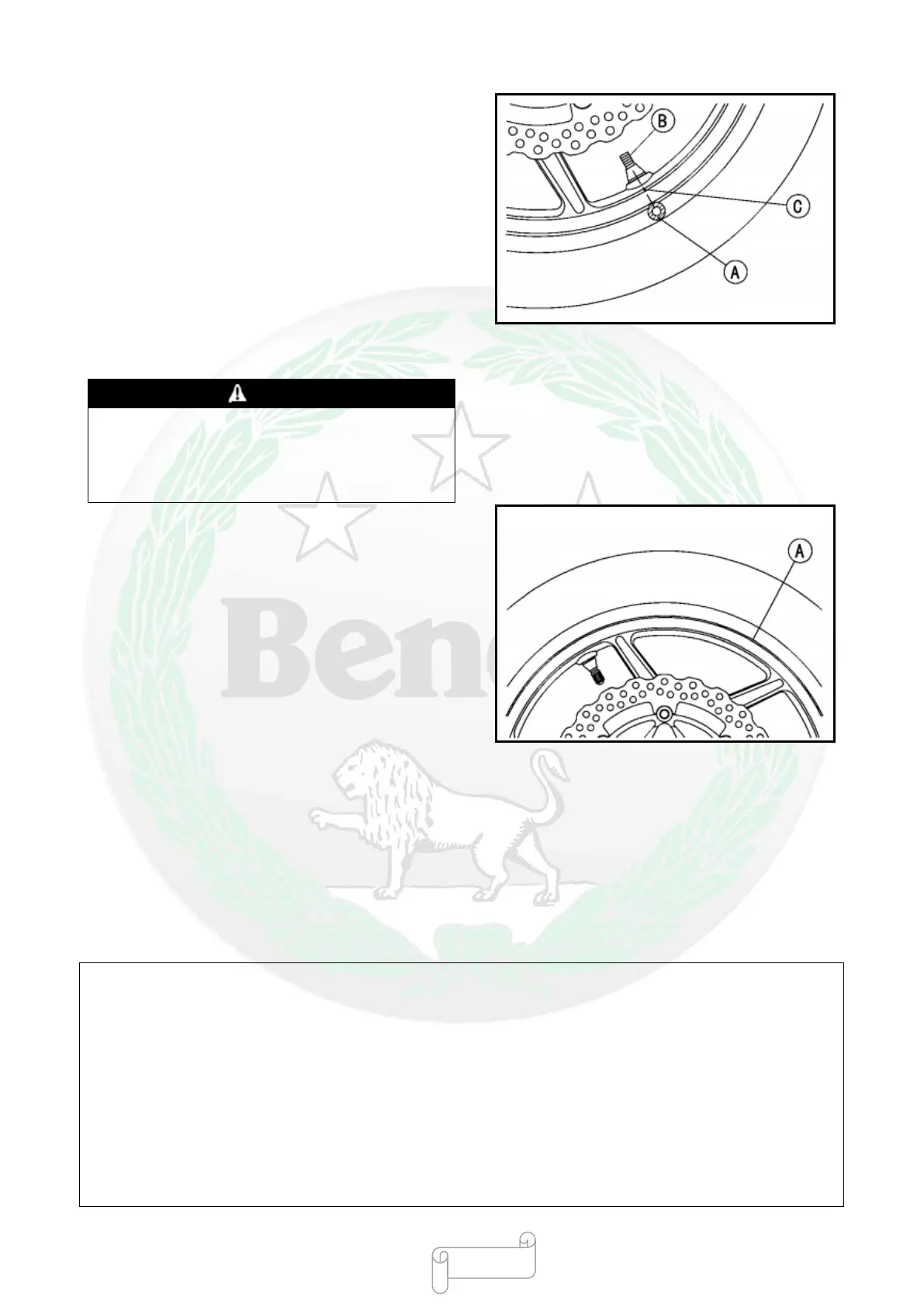

●Put tire on the rim, and align the air inlet valve [A]

with the balance mark [B] on the tire (mark made with a

chalk when the tire is removed or a yellow paint mark

on the new tire).

●Install tire bead at the edge of rim using a tire changer.

●

Lubricate tire bead and rim edges using soap or a

rubber lubricant when inflating the tire, so as to install

the tire bead at the sealing surface of rim.

●Align the tire bead at the rim, inject compressed air

into the tire until the bead engages with the inner

sealing surface of the rim.

When inflating the tires, be sure to install air

inlet valve, and the pressure inside the tire does

not exceed 400 kPa (4.0 kgf/cm

2

). Excessive

inflation may lead to puncture of tire, thus

causing casualties:

●

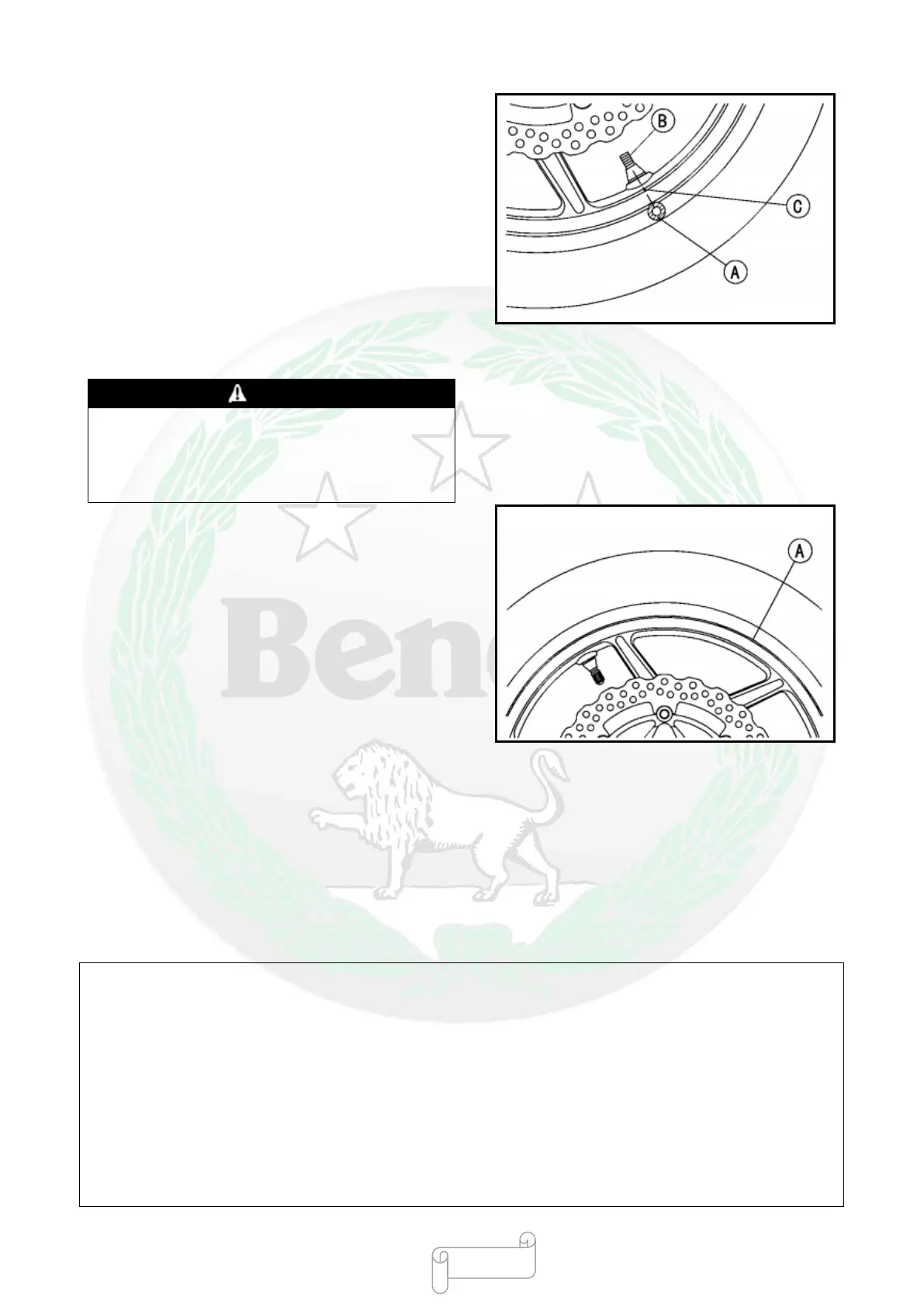

Check whether the rim line [A] on both sides of the

tire’s sidewall is parallel to the edge of the rim.

★ If the edge of the rim is not parallel to the rim line

of the tire sidewall, remove the air inlet valve.

●Lubricate the edges of the rim and bea

d.

●Install the air inlet valve and re-inflate the tire.

●After installing the

bead into the edge of the rim,

check the tire for leaks.

○The air inflated to the tire should be slightly higher

than the standard inflating volume.

○Apply soap to tire or soak the tire in the water. If there

is any air bubble, the tire may leak.

●Adjust the tire pressure according to the specified tire

pressure standard (see “Regular

Maintenance”—“Checking Tire Pressure”).

● Install air inlet valve.

● Adjust the dynamic balance of wheel (see “Adjusting

Dynamic Balance”).

R

epairing Tires

There are t

wo methods commonly used to repair vacuum tires. One is called “temporary (external) repair”: it

does not need to remove the tires from the rim to repair; the other is called “permanent (internal) maintenance”: it

needs to remove the tire to repair. It is

generally believed that compared to a temporary (external) repair,

permanent (internal) maintenance ensures a more durable and stable tire. In addition, permanent (internal)

maintenance has another benefit: associated damage that cannot be found in externa

l examination can be

identified in a thorough examination. In view of this, Benelli does not recommend the use of temporary (external)

maintenance, only recommend the use of reasonable permanent (internal) maintenance. The repair methods

recommended by man

ufacturers may differ slightly. In order to ensure safe ride, please follow the manufacturer’s

recommended repair tools and maintenance materials for repairs.

- 297 -

Loading...

Loading...