80 HEIDENHAIN Technical Manual MANUALplus 620

2.4 General Information

The HEIDENHAIN MANUALplus 620 contouring control was conceived for

standard CNC lathes. The control has an integrated digital drive control and

drives the power modules through PWM signals.

Integrating the drive controllers in the MANUALplus 620 provides the

following benefits:

All the software is contained centrally in the NC; this means that the

individual components of the NC, such as feed axes, spindle, NC and PLC,

are optimally matched.

High control quality, because the position controller, speed controller and

current controller are combined into one unit.

The same functions are available for commissioning, optimizing and

diagnosing feed drives as well as spindles.

The MANUALplus 620 supports lathes up to the following level:

1 slide (NC channel)

6 axes (X/Z/Y/U/V/W axis)

3 spindles (main spindle and opposing spindle, driven tool)

2 C axes (via main spindle drive or with separate drive)

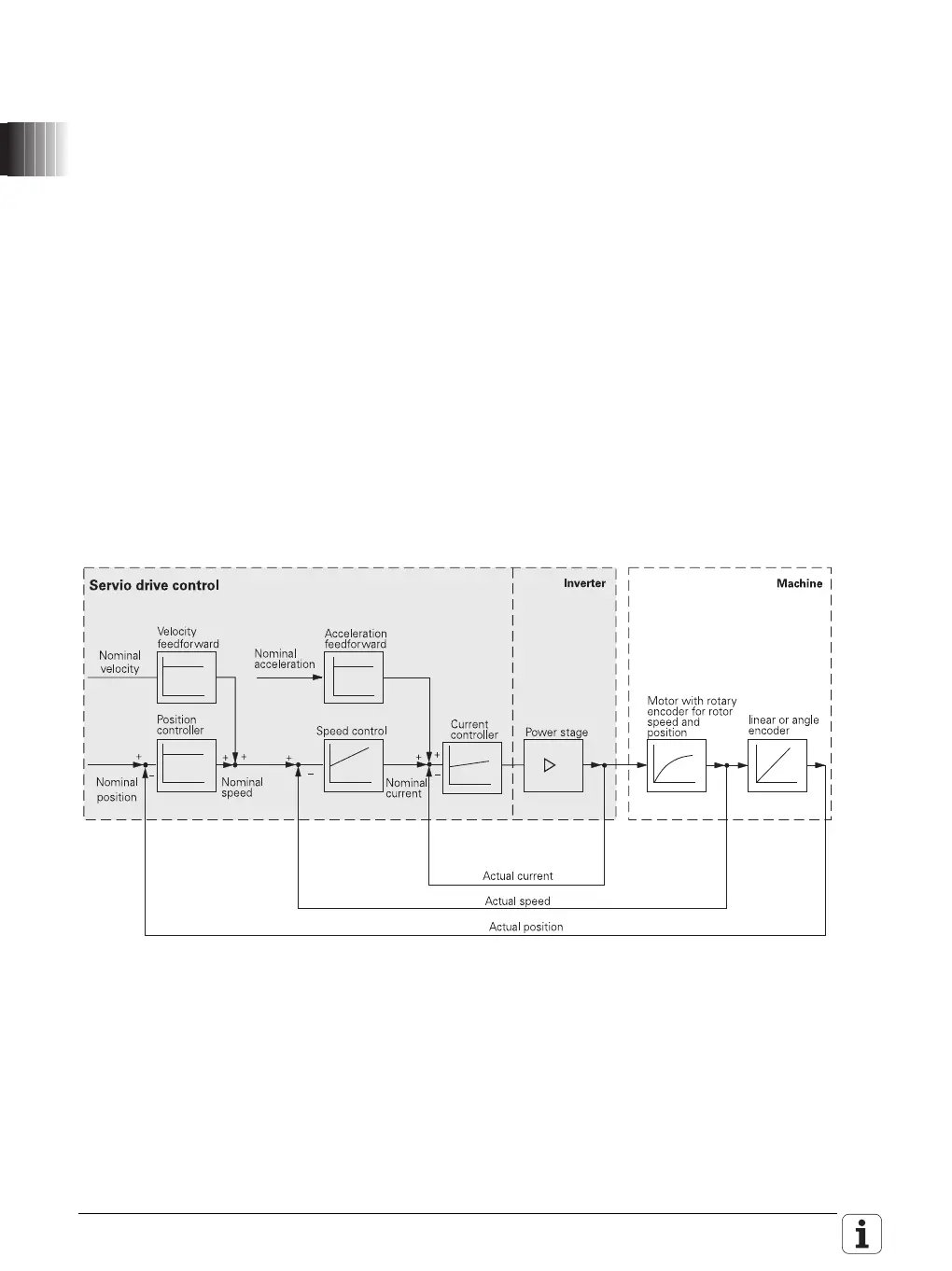

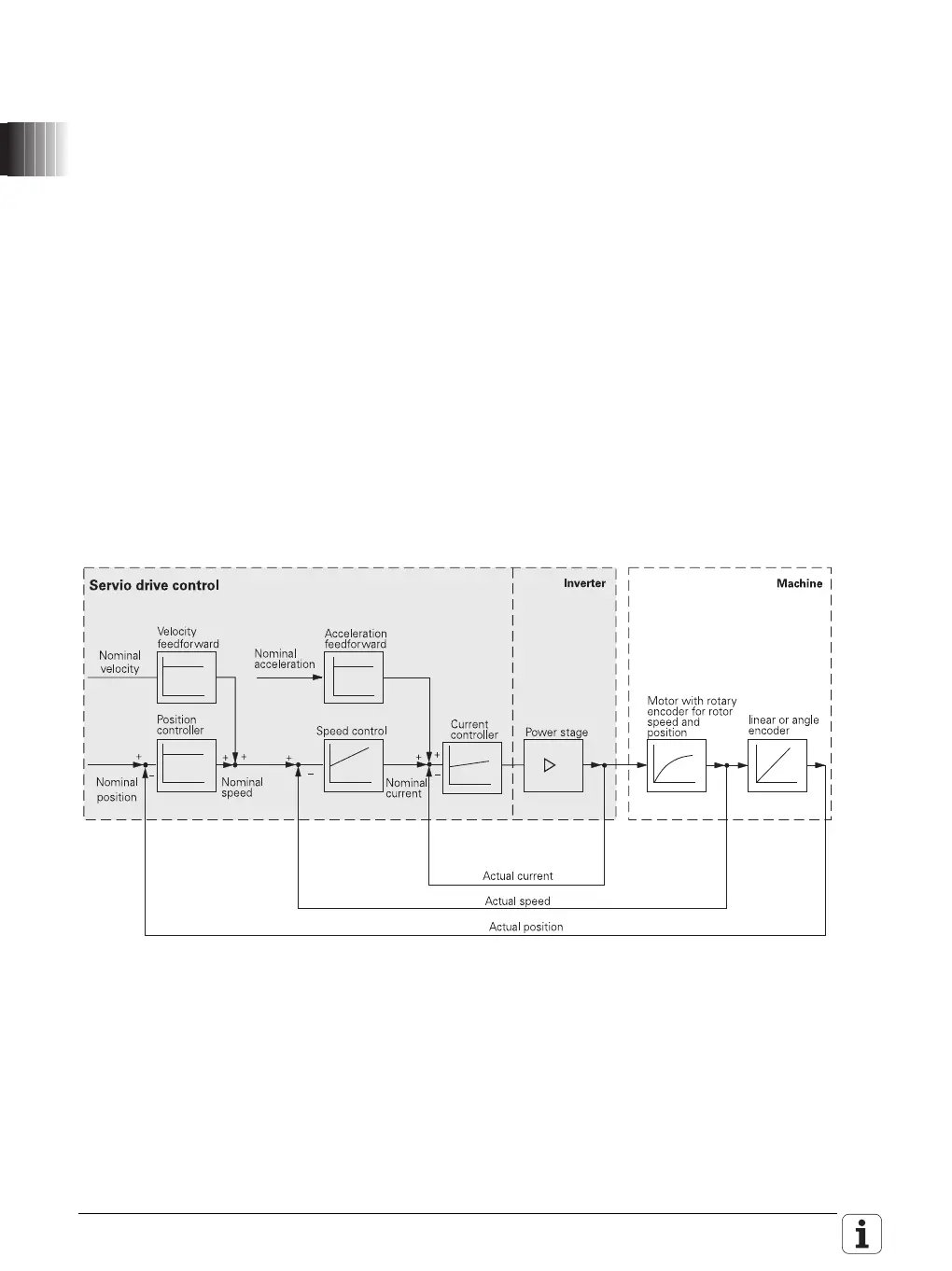

The following diagram illustrates drive control with the use of a rotary encoder

for measuring the actual speed values and a linear encoder or angle encoder

for measuring the actual position values.

The MANUALplus 620 is based on HEIDENHAIN NCK, the software platform

for the HEIDENHAIN control family. Other controls with NCK are, for example,

the TNC 620, TNC 320 or the CNC PILOT 620.

The MC 6110T, the compact main computer of the MANUALplus 620, takes

up very little space, as it is housed in the operating console, directly behind the

integrated 12.1-inch TFT display.

Loading...

Loading...