38 - 2 BeneVision N22/N19 Patient Monitor Operator’s Manual

38.1 Maintenance Introduction

Regular maintenance is essential to ensure that the equipment functions properly. This chapter contains

information on periodic testing and maintenance.

38.2 Maintenance Safety Information

• Failure on the part of the responsible individual hospital or institution using this equipment to

implement a recommended maintenance schedule may cause undue equipment failure and

possible health hazards.

• This equipment contains no user serviceable parts. Refer servicing to qualified service personnel.

• The safety checks or maintenance involving any disassembly of the equipment should be performed

by professional service personnel. Otherwise, undue equipment failure and possible health hazards

could result.

• Do not open the equipment housings. All servicing and future upgrades must be carried out by the

service personnel trained and authorized by Mindray.

• Do not open batteries, heat batteries to above 60 °C, incinerate batteries, or short the battery

terminals. Batteries may ignite, explode, leak or heat up, causing personal injury.

• No modification of this equipment is allowed.

• If you discover a problem with any of the equipment, contact your service personnel or Mindray.

• The service personnel must be properly qualified and thoroughly familiar with the operation of the

equipment.

• At the end of its service life, the equipment, as well as its accessories, must be disposed of in

compliance with the guidelines regulating the disposal of such products. If you have any questions

concerning disposal of the equipment, please contact Mindray.

• When disposing of the packaging material, be sure to observe the applicable waste control

regulations and keep it out of children’s reach.

• Use and store the equipment within the specified temperature, humidity, and altitude ranges.

38.3 Maintenance and Testing Schedule

Follow the maintenance and testing schedule or local regulations to perform testing and maintenance. Make

sure to clean and disinfect the equipment before taking any tests and maintenance

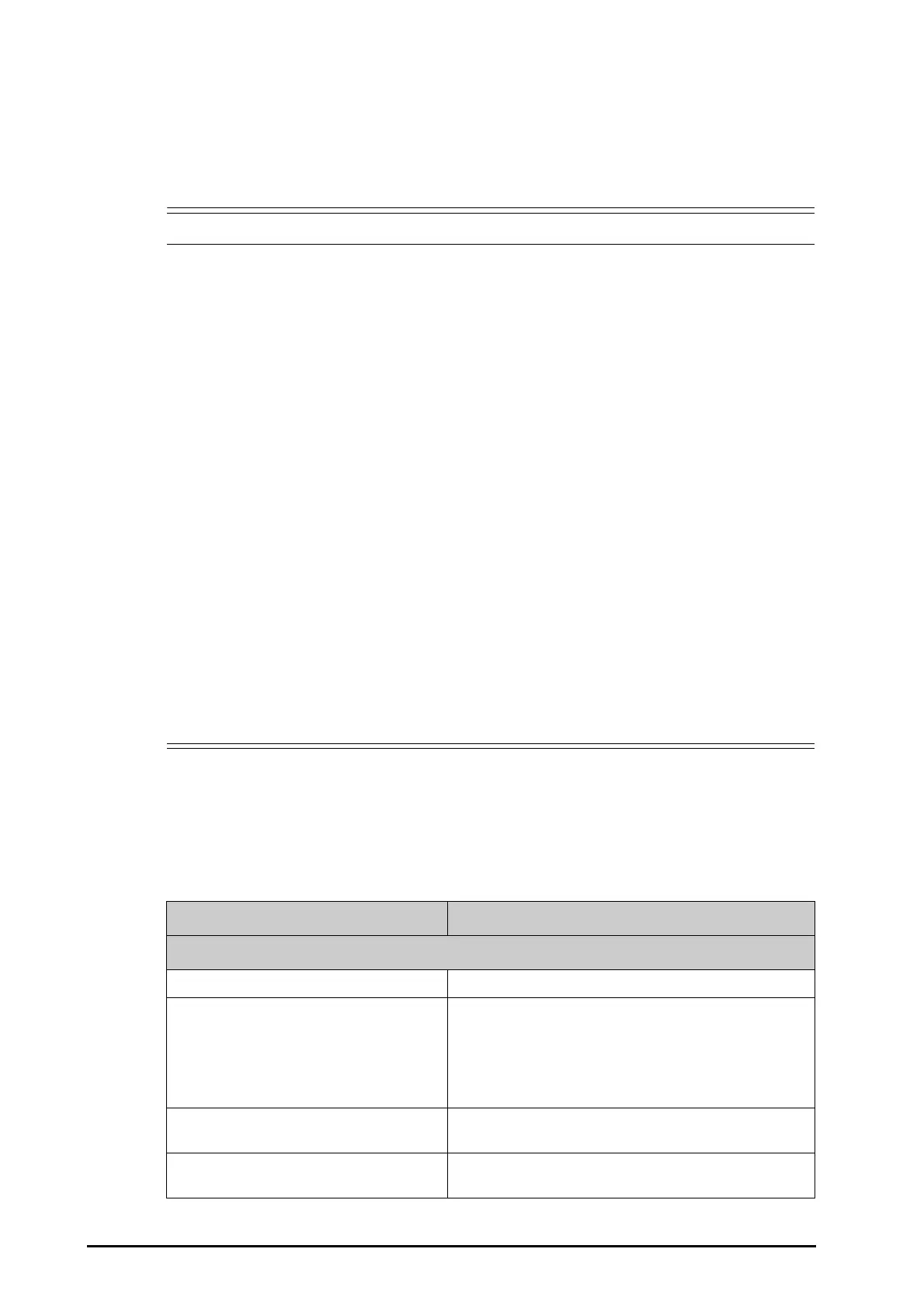

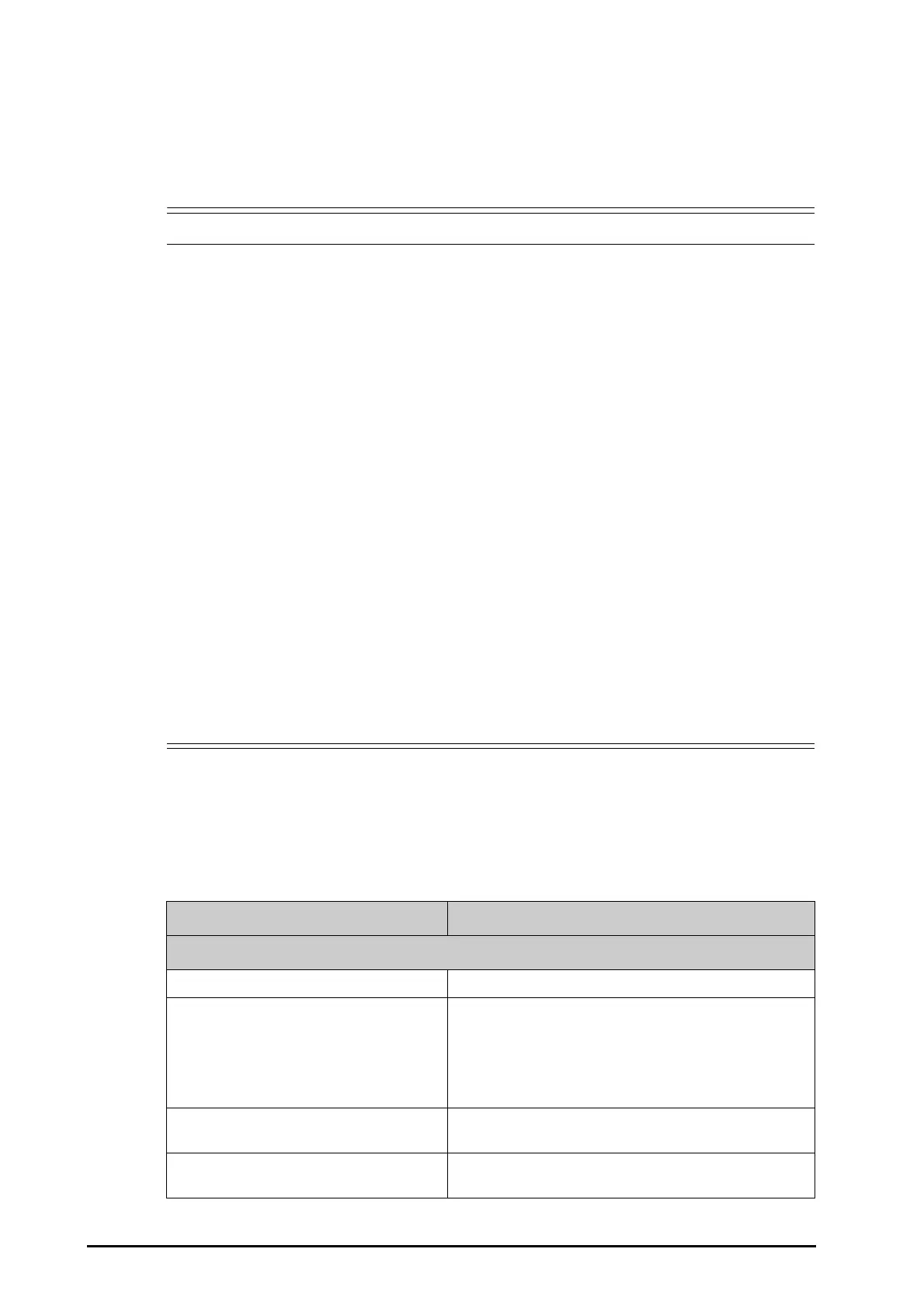

The following table lists the maintenance and testing schedule:

Test/Maintenance Item Recommended Frequency

Performance Tests

Visual inspection Every day, before first use.

Measurement module performance test and

calibration

1. If you suspect that the measurement values are incorrect.

2. Follow any repairs or replacement of relevant module.

3. Once a year for CO2 and AG tests.

4. Once every two years for other parameter module performance

tests.

Analog output test If you suspect that the analog output function does not work

properly.

Defibrillation synchronization test If you suspect that the defibrillation synchronization function does

not work properly.

Loading...

Loading...