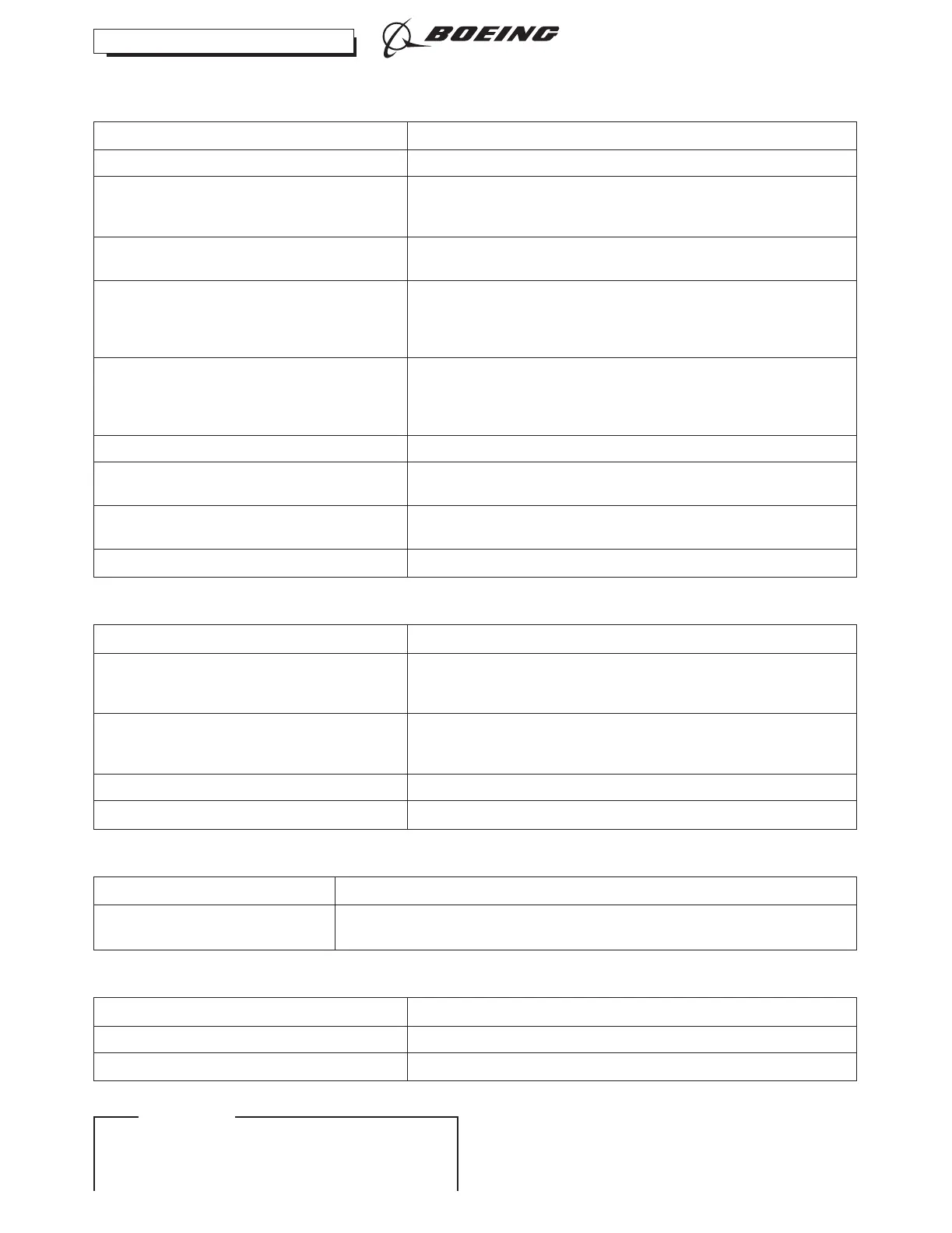

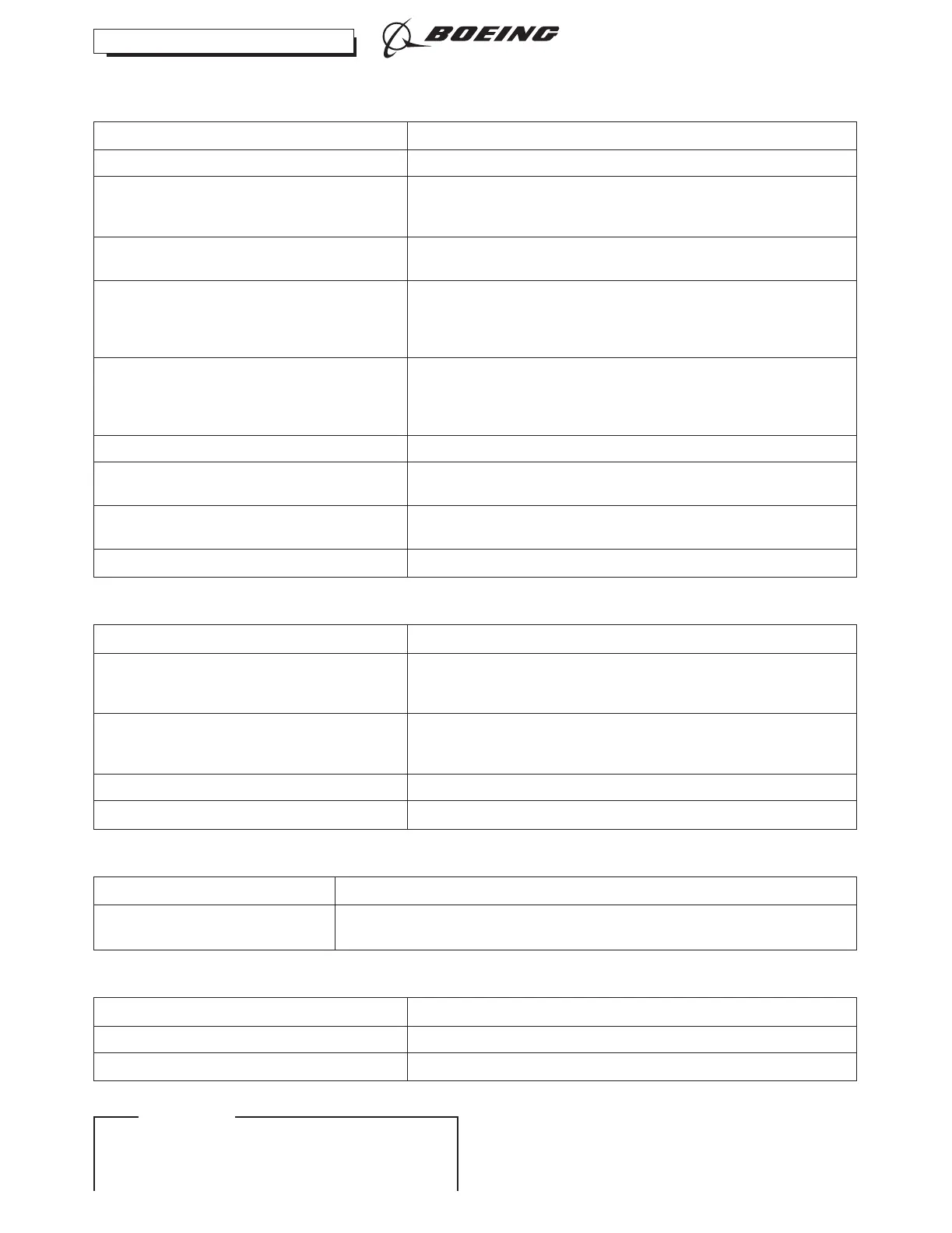

Condition Maximum Serviceable Limits

Cracks in the metal Not serviceable.

Weld cracks Permitted if less than 0.06 inch (1.5mm) in the axial direction, and less

than 0.10 inch (2.5 mm) in the transverse direction. There must be at

least 0.50 inch (13 mm) between each crack.

Dents Permitted if they are smooth and less than 0.250 inch (6.35 mm) in

depth.

Nicks, scores and scratches in the axial direction Permitted if less than 0.015 inch (0.38 mm) in depth, and 1.0 inch (25.4

mm) in length. There must be at least 1.0 inch (25.4 mm) between

each sign of damage after the high metal has been removed. The

metal must not be less than 75% of its initial thickness.

Nicks, scores and scratches in the

circumferential direction

Permitted if less than 0.030 inch (0.76 mm) in depth, and 1.0 inch (25.4

mm) in length. There must be at least 1.0 inch (25.4 mm) between

each sign of damage after the high metal has been removed. The

metal must not be less than 75% of its initial thickness.

Thread damage on the bosses One full thread can be removed. Chase the threads.

Hot spots (discoloration) Permitted if the metal is not crazed. No cracks are permitted. Do the

combustor borescope inspection (Ref 72-00-00).

Bulges Not serviceable when found with heat discoloration or cracks. Do the

combustor borescope inspection (Ref 72-00-00).

Corrosion Permitted if the metal is not less than 75% of its initial thickness.

SUBTASK 72-40-00-216-006-G00

(5) Visually examine the pads (does not include the strut pads) for the conditions that follow:

Condition Maximum Serviceable Limits

Nicks, scores and scratches on the sealing

surface

Permitted if less than 0.30 inch (0.76 mm) in depth. After the high

metal has been removed, the damage must not extend across more

than half of the sealing surface.

Thread damage (except on the fuel nozzle pad) ) The damage can be one full thread (after the thread has been chased).

If the damage is more than one thread, install the insert (Ref

72-40-00).

Thread damage (on the fuel nozzle pad) The damage can be one full thread (after the thread has been chased).

Cracks Not serviceable.

SUBTASK 72-40-00-216-007-G00

(6) Visually examine the borescope ports for the conditions that follow:

Condition Maximum Serviceable Limit

Damaged threads Not serviceable. One full thread can be removed if the remaining threads are not

damaged.

SUBTASK 72-40-00-216-008-G00

(7) Visually examine the strut pads for the conditions that follow:

Condition Maximum Serviceable Limits

Cracks in the strut ends Permitted if they do not let the air leak through the cracks.

Cracks in the bolt holes One bolt hole in each flange can have a radial crack.

767

AIRCRAFT MAINTENANCE MANUAL

CF6-80A SERIES ENGINES

72-40-00

NoC

Page 603

D633T1B7 Dec 22/2016

ECCN 9E991 BOEING PROPRIETARY - Copyright © Unpublished Work - See title page for details

EFFECTIVITY

ABX 001-007, 011, 012, 016-019, 021, 022, 025, 101,

109, 114, 115, 314-999

Loading...

Loading...